Environmentalists and code regulators continue to place more emphasis on green, or sustainable, roof systems, and roofing professionals are successfully adapting to these changing technologies. SPRI is no exception.

The past year has been one of the most challenging—and productive—ever for SPRI and its members. The association, which represents sheet membrane and component suppliers to the commercial roofing industry, has worked overtime to stay ahead of a dizzying array of industry developments.

Among SPRI's most important accomplishments in 2010 was the release of key standards for vegetative roof systems. The association also announced the results of an Oak Ridge National Laboratory (ORNL) study showing vegetative roof systems can reduce heating and cooling costs.

"Among other things, SPRI is developing codes and standards for contractors, specifiers, consultants and others that will help take the mystery out of vegetative roof systems and the term's relationship to cool roofs, garden roofs and energy-efficient roofing," says SPRI President Dave Bailie, regional sales manager for USG Corp. SECUROCK® Gypsum-Fiber Roof Board, Chicago.

ANSI approves standards

The American National Standards Institute (ANSI) recently approved two of three standards for vegetative roof systems developed by SPRI in cooperation with Green Roofs for Healthy Cities (GRHC).

ANSI/SPRI VF-1, "External Fire Design Standard for Vegetative Roofs," was approved Jan. 29, 2010. SPRI also completed ANSI/SPRI RP-14, "Wind Design Standard for Vegetative Roofing Systems," a wind standard for vegetative roof systems.

The recently released ANSI/SPRI VF-1 fire design standard includes fire-control designs to limit the spread of flame if a vegetative roof system were to catch fire. The standard uses barriers of nonvegetative zones to contain a potential fire.

The VF-1 standard is intended to provide a minimum design and installation reference for those who design, specify and install vegetative roof systems. It also can be used with manufacturers' installation specifications and requirements for specific products used in vegetative roof systems.

The standard specifies use of fire stop walls and fire break roof areas. Fire walls must be of noncombustible construction and extend above the roof surface a minimum of 36 inches.

The fire break roof areas must consist of a Class A-rated roof system that creates a minimum 6-foot-wide continuous border around the vegetative roof. Fire break roof areas also must be included where vegetative roof systems abut vertical surfaces, such as rooftop structures, equipment and roof penetrations.

Fire stops also are specified to protect large roof areas from the spread of fire. Incorporating the border zones into expansion joints or roof area dividers also are recommended by the standard—and NRCA-wherever possible.

"This was truly an industry effort including manufacturers, vegetative roofing professionals, testing organizations, contractors, design professionals and consultants," Bailie says.

ANSI/SPRI RP-14 2010 provides design guidelines associated with wind uplift and stone scour; it defines items such as setbacks from the edges of roofs in areas with high winds, use of wind erosion mats and edging details. The standard also discusses the various types of materials and their behavior under varying wind conditions.

A third vegetative roofing document, a root penetration standard for vegetative roof systems, GRHC-SPRI VR-1, "Procedure for Investigating Resistance to Root Penetration on Vegetative Roofs," should be approved by ANSI this month.

Saving energy

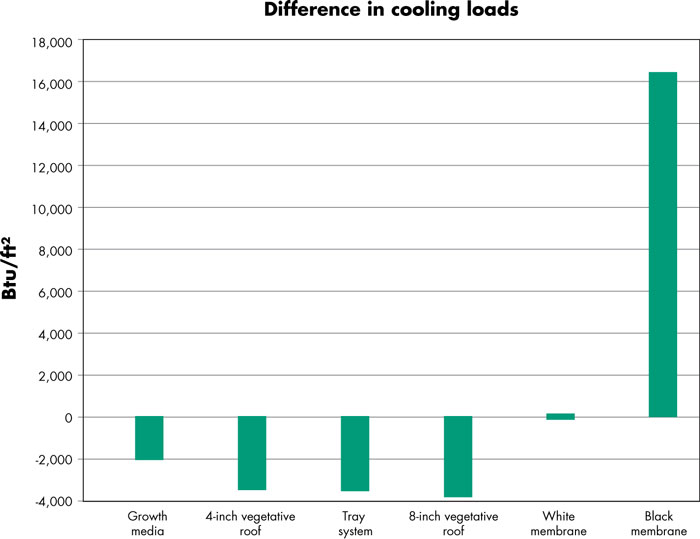

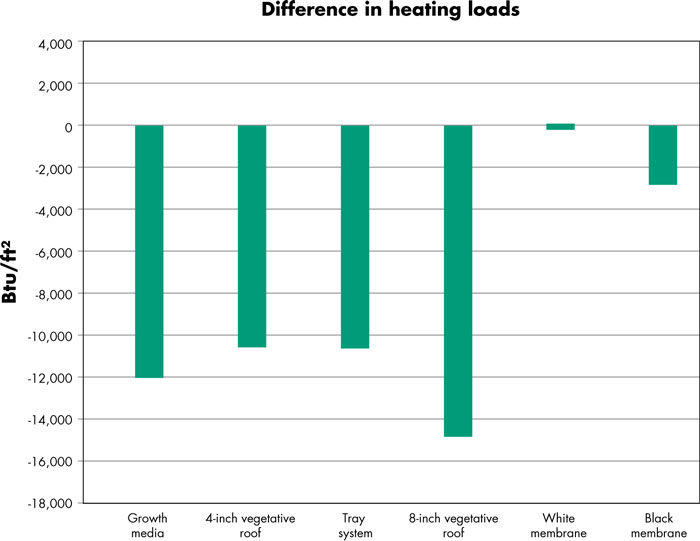

In another effort to better understand vegetative roof system performance, SPRI and ORNL completed a study showing vegetative roof systems can help reduce heat gains and losses, resulting in significant energy savings in mixed climates. The reduction in heat gains during cooling-dominated periods—and heat losses during heating-dominated periods—shown in the study translates to lower heating and cooling demands for the conditioned space. (See Figures 1 and 2.)

Figure 1: The SPRI/ORNL vegetative roof study measured cooling loads of vegetative and black roof sections indexed to the white section cooling load.

The SPRI/ORNL study accurately measured the annual cooling and heating loads per unit area of three vegetative roof systems. The study also included side-by-side comparisons with black and white roof systems, as well as a test section with just the growth media without plants. The low-slope roof systems were constructed for continuous monitoring in east Tennessee's mixed climate (see Photo 1).

The study notes the energy savings offered by vegetative roof systems are climate-dependent and affected by the efficiencies of heating and cooling equipment. The study results also show lower membrane temperatures and temperature fluctuations were experienced by the vegetative roof systems than the control black EPDM and white TPO roof systems.

A summary of the study, "Thermal Performance of Vegetative Roofs," is available at www.spri.org.

In the future, SPRI and ORNL hope to model the internal heat flow for the vegetative roof systems with the STAR computer model.

Figure 2: The SPRI/ORNL vegetative roof study measured heating loads of vegetative and black roof sections indexed to the white section heating load.

STAR is a transient one-dimensional finite difference model for heat conduction. The model simulates heat flow in multilayer roof systems. This will require materials with known properties, such as thermal conductivities and specific heats.

The validated STAR computer model will be used to predict energy use in roof systems with different insulation levels and in climates different from the test climate. Future work also will include evaluation of R-value trade-off in these systems.

Other SPRI standards

SPRI continues to provide information about codes and standards for the roofing industry. During 2010, SPRI submitted 12 proposed code changes to the International Building Code. Two were recommended for approval.

SPRI and the roofing industry also were represented at International Green Construction Code (IGCC) meetings. The association submitted four proposed code changes to IGCC and attended the group's first Technical Committee meeting in August 2010. SPRI will continue to be involved with IGCC's development, specifically regarding volatile organic compounds and energy requirements as they pertain to single-ply roof membrane systems.

SPRI also is investigating the effect roof membrane color has on moisture accumulation in roof assemblies. SPRI will present a paper on this topic at NRCA's 2011 International Roofing Symposium, which will be held Sept. 7-9 in Washington, D.C., in cooperation with ORNL and the National Roofing Council Canada.

Another important standard completed in 2010 is ANSI/SPRI GD-1, "Design Standard for Gutter Systems Used with Low-Slope Roofs." The standard specifies structural design for gutters used with low-slope roof systems. The standard does not address water removal or the water-carrying capability of gutters because other building codes already address these issues.

SPRI/FM 4435-ES-1 2010, "Wind Design Standard for Edge Systems Used with Low Slope Roofing Systems," is the draft revision to SPRI ES-1 that currently is in the ANSI canvassing process and will be an update to ES-1-2003. It combines SPRI and FM Global requirements and provides basic requirements for wind-load resistance testing and design for roof-edge securement, flashing systems and nailers.

The standard also provides minimum fascia thicknesses that lead to satisfactory flatness and designs to minimize corrosion. It is intended to be used with manufacturer specifications and requirements of specific roofing materials and edge systems used in roof assemblies, excluding gutters.

The latest draft to ES-1 combines the performance requirements included in the current version of ES-1 and requirements addressed in FM 4435, "Approval Standard for Roof Perimeter Flashing."

Fastener corrosion

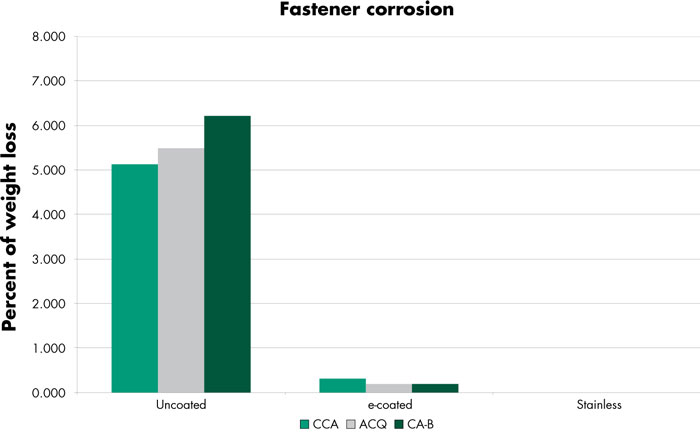

SPRI ES-1 specifically was designed to address the issue of roof perimeter edge failures. Along these lines, SPRI, ORNL, NRCA and RCI Inc. also investigated the role fastener corrosion may play in roof edge failures and whether metal fastener corrosion in treated lumber is an issue.

Figure 3: SPRI found uncoated fasteners exposed to ACQ/CA-B treatments exhibited greater corrosion than those exposed to the CCA treatment.

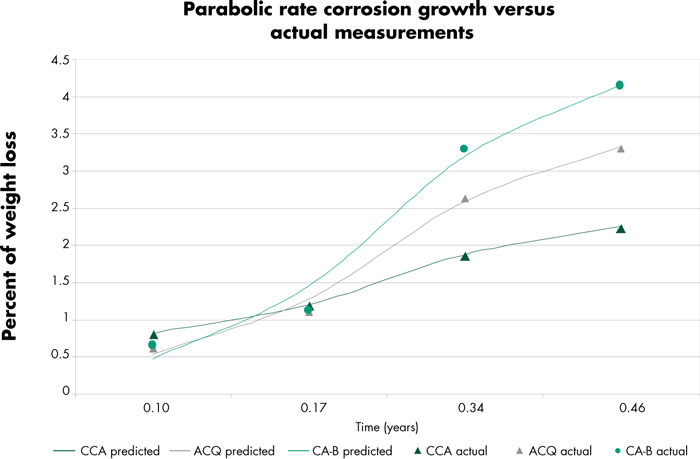

The study, "Evaluation of Metal Fasteners Corroded from Contact with Preservative Treated Wood," assessed the relative corrosion levels of various fasteners used with CCA, ACQ and CA-B lumber. (See Figures 3 and 4.)

SPRI's studies were limited to low-slope roofing applications, and laboratory tests were conducted to identify critical temperature and humidity conditions required to initiate corrosion. Field tests also were conducted to determine whether corrosive conditions exist in low-slope commercial roofing applications.

The study showed no reports of excessive fastener corrosion when installed in treated wood nailers. However, SPRI recommends the roofing industry:

Figure 4: Coated fasteners exposed to ACQ/CA-B exhibited less corrosion than those initially exposed to the CCA treatment.

The study results are available at www.spri.org.

Insulation adhesives

In summer 2010, another standard, ANSI/SPRI IA-1 2010, "Standard Field Test Procedure for Determining the Mechanical Uplift Resistance of Insulation Adhesives over Various Substrates," was reaffirmed by ANSI.

ANSI/SPRI IA-1 was developed to provide a uniform field testing procedure to determine whether using an insulation adhesive is suitable to attach insulation or cover board to a substrate. The standard is intended primarily for situations when an existing roof system is being replaced or re-covered and the general condition of the substrate is in doubt.

However, the procedure also applies to new construction. The uplift data obtained provides manufacturers and design professionals with pull-resistance values that will assist in verifying the suitability of intended designs.

"It has been a busy and challenging year for SPRI and its members, and the association is committed to focusing on the most important issues facing the commercial roofing industry in 2011," Bailie concludes. "We are already beginning to work on a number of new technical initiatives that were discussed during SPRI's annual meeting in January."

One initiative is the development of guidelines to define the successful use and limitations of using waterborne bonding adhesives with TPO, PVC and EPDM single-ply membranes. Concerns about the efficacy of water-based adhesives and/or application methods were expressed by NRCA Associate Executive Director of Technical Services Mark Graham. A SPRI task force has been created to investigate the issue and develop guidelines for the use of such adhesives if necessary.

SPRI will report its findings on these and other industry-related technical issues in the coming months.

Mike Ennis is SPRI's technical director.

COMMENTS

Be the first to comment. Please log in to leave a comment.