Adhered single-ply membrane roof systems came into use during the latter part of the 1970s. At the time, the primary bonding adhesives in use were made from solvent-based neoprene, and the classical roof insulation boards used were wood fiberboard, perlite and rigid fiberglass with asphalt-adhered kraft paper facers. Neoprene adhesives typically were loaded with toluene and hexane; these strong solvents are needed to dissolve and carry the neoprene polymer matrix. The volatile organic compound (VOC) level in some of the original formulations was at or near 450 grams per liter.

A good bonding adhesive mates two dissimilar surfaces together; has good initial and long-term bond strength with high shear resistance; withstands large temperature swings; and resists spread of flame. The original neoprene and solvent-based adhesives were 25 percent solids (nominal); the remainder was a mixture of volatile compounds (solvents).

By the 1990s, air quality became a hot topic, and many states (and regions) set up air-quality control standards. VOC materials used in roofing came into sharp focus as the highly volatile materials can contribute to ground-level ozone as oxides of nitrogen combine with VOCs in the presence of sunlight and heat.

A new player

The roofing industry ended up facing VOC limits of 250 grams per liter for single-ply bonding adhesives in 1989 per the state of California and the South Coast Air Quality Management District. By the early 2000s, the roofing industry was slowly facing the realities of developing quality low-VOC adhesives, which was not easy. So a push toward water-based adhesives took hold, and by 2010, the products were in many roof system specifications.

Water-based adhesive technology is different and typically costlier than the older high-VOC bonding adhesives. And because water is the solvent, rooftop temperature, humidity and wind conditions come into play. A concern for water-based materials in northern U.S. climates is freezing temperatures. One cannot leave a 5-gallon pail of water-based adhesive outside to freeze—frozen material needs to be discarded. Application temperatures generally are restricted to 40 F and rising.

A research study

To better understand the new adhesives, a joint NRCA and Midwest Roofing Contractors Association (MRCA) study of water-based adhesives examined various performance traits, including dry down time and reaction to moisture and wet environments (see "Studying water-based adhesives," for more about the study).

Four water-based adhesive products were selected for study. The first three manufacturers all had multipurpose acrylic bonding adhesive products that could be used to bond different membrane types. The Sika® Sarnafil Sarnacol 2121 product was chosen because of its time in use in the roofing market—the formulation had been in use since 1979 when it was formulated in Switzerland as a vinyl acetate latex copolymer; it earned FM Approvals' (FM) approval by 1980.

During the NRCA/MRCA study's initial phase, a significant amount of time and effort went into the four- and 24-hour film dry down behavior of the water-based adhesive products under varying temperature and humidity conditions. They all behaved quite similarly regardless of temperature and humidity conditions.

Water soak tests

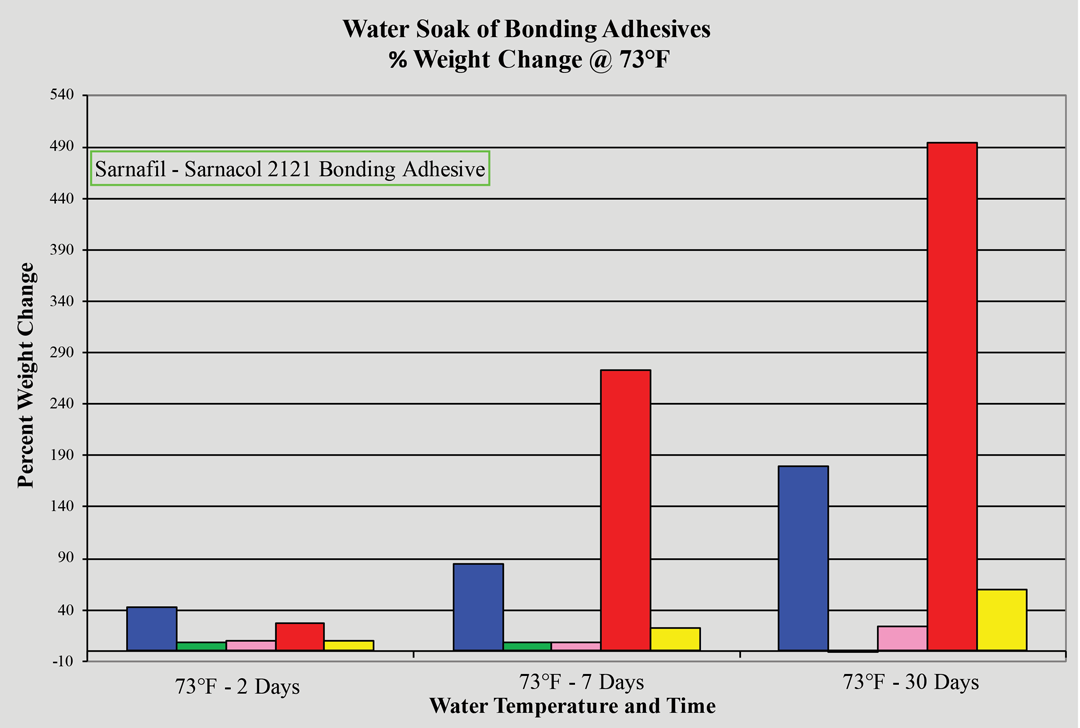

The water-based adhesives were cast onto individual aluminum plates at their specified coverage rates and allowed to air dry for seven days (no weight change was observed). Then, they were set in shallow glass dishes; water was added to cover the water-based adhesive film by 1/8 of an inch. Weight change was monitored periodically; the results are shown in Figure 1. The dark green bar in Figure 1 represents the weight gain of Sarnacol 2121, and the other colors represent the other adhesives' weight gain.

Figure 1: Weight change of water-based adhesives following a water soak test |

A significant difference of water pickup exists among these film samples. The red and blue bars are the results from two separate 5-gallon pails from one manufacturer. The pink and yellow bars are single-pail samples from other manufacturers. Basically, the Sika Sarnafil adhesive began a slight weight loss at 30 days while the other products had an accelerated water pickup. Water pickup means the product is re-emulsifying, which leads to a loss of bond strength. The roof membrane then becomes de-bonded, and an attachment failure presents itself as areas of loose membrane develop all over the roof. It was clear the Sarnacol 2121 formulation was different.

Membrane and insulation

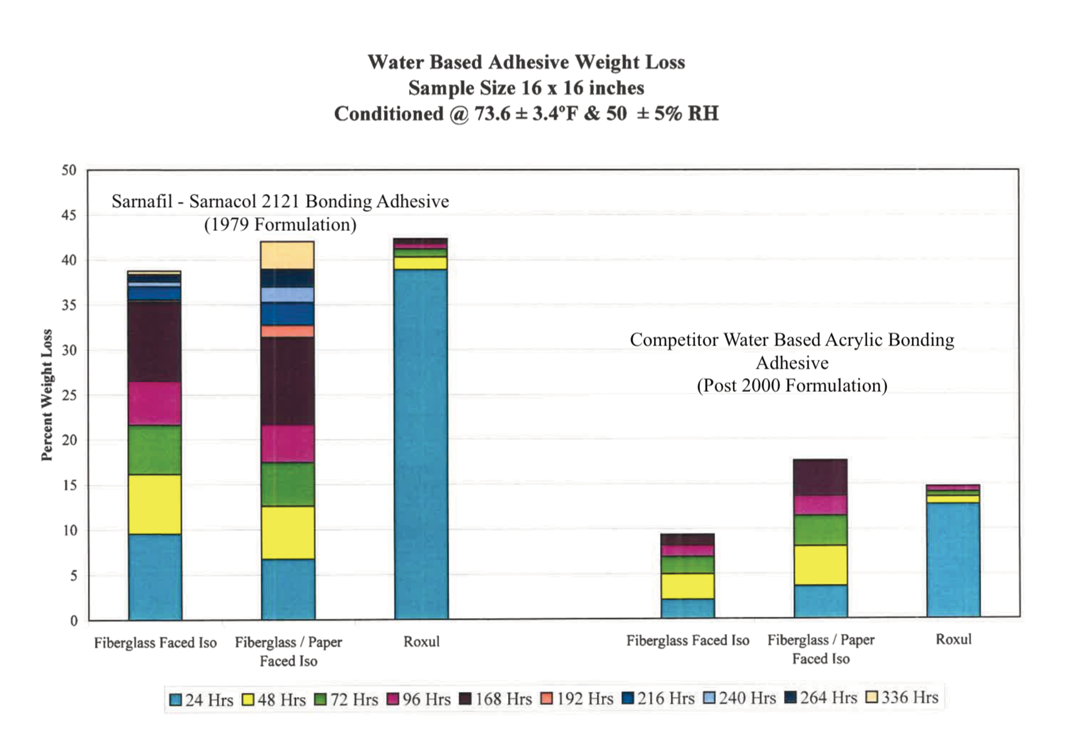

The series of tests also involved assembling 16- by 16-inch roof system samples of insulation and roof membranes bonded with water-based adhesives. The polyisocyanurate boards were 2 inches thick. The stone wool used in the study was a 2-inch dual-density product. Each sample was assembled at the specified coverage weight of water-based adhesive, which was 100 to 120 square feet per gallon (double-sided) for the acrylic polymer-based product and 133 square feet per gallon (one-sided wet method) for the Sarnacol 2121 adhesive. The two-sided applications were assembled when they became tacky to the touch; the one-sided wet method was used for the Sarnacol 2121 with the membrane being placed immediately into the adhesive.

As shown in Figure 2, the 1979 Sarnacol 2121 formulation experienced a faster dry down than the other manufacturers' water-based adhesives shown in the right-hand columns. Of special interest is the amount of water loss. The Sarnacol 2121 had 52 percent solids content while the other water-based adhesives had 58 percent solids content. To make sure the roofing materials did not change weight, side-by-side weight changes were made on individual samples of insulation and membrane. To complete the roof assembly samples, 60-mil-thick PVC and 60-mil-thick TPO membranes were used, respectively. Therefore, the net weight change shown is water loss.

Figure 2: Water loss in water-based adhesives following a water soak test |

Of special note is the Sika Sarnafil adhesive shows a near complete water loss while the other manufacturers' adhesives had about one-third of that (42 percent average loss versus 15 percent). Again, there is an obvious difference among these formulations regarding water soak and water loss after assembly. The stone wool material showed a markedly rapid dry down, which is believed to be related to the material's permeability. On the other hand, fiberglass-faced products do not dry down as quickly as paper-faced polyisocyanurate insulation boards.

FM

In 1979, Sika Sarnafil requested FM test its PVC membranes using Sika Sarnafil's water-based adhesives as the bonding adhesive for adhered roof systems. The highest wind-uplift rating available from FM at that time was Class I-90, and Sarnacol 2121 was granted that rating when used as the bonding adhesive over 3/4-inch perlite, 1-inch wood fiberboard and 1 1/2-inch perlite-foam composite board. The insulation boards were to be laid in hot asphalt.

In 1982, FM issued a new approval, which again included a Class I-90 wind-uplift rating for Sarnacol 2121 adhered membranes but reflected a list of new mechanical fasteners that were approved for fastening insulation boards to steel deck. This began FM's change to mechanically fastening insulation boards to steel decks.

In 2011, FM issued a new approval specific to the reduction in application rate for Sarnacol 2121 in Class 1 roof assemblies to 0.75 gallons per square as it was determined one could reduce the amount of adhesive while maintaining the same uplift ratings. The application method went from a 1/4-inch notched squeegee to the roller or spray method with the membrane set into the wet adhesive. A wider range of wind-uplift ratings also was issued by FM for fiberglass-reinforced PVC membranes adhered to insulation boards, including:

The 2011 FM approval has high wind-uplift capacities specific for fully adhered PVC systems for use in the High Velocity Wind Zones of coastal Florida. This indicates the uplift resistance of a cured film of Sarnacol 2121 in terms of pounds per square inch (psi). When developing composite insulation boards such as layers of wood fiberboard product or the internal tensile strength of a perlite board, the goal is to have a minimum of 5 psi of tensile. Rigid foam polyisocyanurate insulation boards easily will reach this number.

The High Velocity Wind Zone uplift is rated at 525 pounds per square foot (psf), which is 3.65 psi. We do not know what the failure mode was in the FM evaluation of the Class I-525 system using Sarnacol 2121, but it is safe to say at least 3.65 psi apparent tensile strength was present in the glue line. It should be noted a 525-psf uplift would destroy all but a heavy concrete building; therefore, the Sika Sarnafil adhesive installed in 1979 will not be the weak link in a system for wind-uplift resistance if applied correctly. The field performances of aged adhered installations may tell us more.

History of field performance

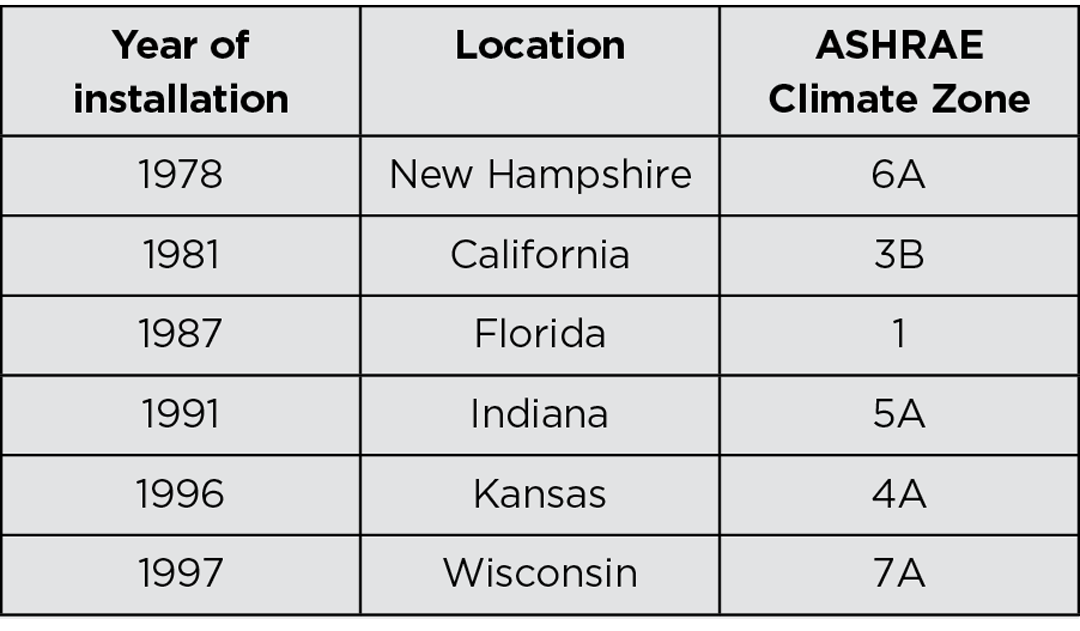

A review of in-service records of adhered roof assemblies using water-based adhesives was completed in late 2017. Figure 3 shows a small sampling of age, location and ASHRAE Climate Zones for roofs older than 20 years. Photo 1 shows a 1987 Miami roof system installation with tile roof mansards present. Photo 2 shows a 1995 school roof in Massachusetts. Photo 3 is a 1981 California roof system undergoing perimeter remediation because of a change in the edge metal; the field of the 1981 roof continues to be in service as adhered with the 1981 Sarnacol 2121 water-based adhesive. Note the first layer of the original perlite substrate board was adhered with hot asphalt.

Figure 3: Sampling of ASHRAE Climate Zones for roofs older than 20 years |

It is quite conceivable some of these aged installations experienced high-wind velocity conditions at some point in their lives and remain in service. In fact, the Miami roof system not only survived Hurricane Andrew in 1992, but it also was in the path of Hurricane Irma in 2017 and performed well with no damage.

A solid performer

Sarnacol 2121 water-based adhesive dates to 1979 when it was brought from Switzerland for use by Sika Sarnafil in Canada and the U.S. The 2013-14 NRCA/MRCA test programs on water-based adhesive have shown Sarnacol 2121 has low water absorption when compared with newer competitive water-based adhesive formulations tested. The research also demonstrated Sarnacol 2121 experiences almost a total water loss from the adhesive upon dry down in the tested roof assemblies when compared with other water-based adhesive formulations. In addition, Sarnacol 2121 is not subject to re-emulsification as demonstrated by its decades of use without change to the formula. Some newer water-based adhesive products have been changed because of re-emulsification issues.

A 2017 review of the in-service records of some adhered PVC roofs using water-based adhesives was made. Interestingly, the age spans of in-service roofs dated to 1978—a span of 38 years of field performance. Not even the original solvent-based neoprene adhesives performed that long. The 38-year time span of performance also covered the wide range of climate zones in the U.S. from hot and humid to cold and dry. What is remarkable in hindsight is the fact that Swiss formulators came up with the Sarnacol 2121 formulation in 1979. This was long before our European friends who wildly exported roofing materials to the U.S. during that time period really understood our huge climatic differences.

As an experienced researcher of roof system materials, it certainly appears to me that the 1979 water-based adhesive formulation is a solid performer; it has been out there quietly working where needed. It was not until current clean-air regulations caused the roofing industry to seek out water-based adhesive materials that we realized the history of the Swiss-formulated Sarnacol 2121 and its nearly four decades of performance as a bonding adhesive in the U.S.

Rene Dupuis, Ph.D., P.E., is principal with SRI, Middleton, Wis.

Studying water-based adhesives

The diminished use of solvent-based adhesives to bond roof membranes brought about the use of water-based bonding adhesives. This shift primarily was driven by concerns regarding regional outdoor air quality; oxides of nitrogen combine with volatile organic compounds (VOC) from solvent-based adhesives and can produce ground-level smog.

NRCA and Midwest Roofing Contractors Association technical committees sponsored an in-depth study of water-based adhesives during 2013-14 to study the following:

The four water-based adhesive products tested were Carlisle Aqua Base 120; Firestone Water Based Bonding Adhesive P; GAF WB 181; and Sika Sarnafil Sarnacol 2121. The first three are acrylate base polymer systems, and the last (and oldest) is a polyvinyl alcohol/acetate mixture. Other additives are present; these products are all subject to freezing as water is the primary component. Solids contents range from 50 to 58 percent.

Following is a summary of five test protocols:

Roof system designers should be aware of the potential for water vapor drive from a building's interior to a single-ply roof assembly for some water-based adhesives as re-emulsification could occur. A vapor retarder should be used, especially over new concrete roof decks.

Roof system designers also should incorporate the use of fiberglass facers when using polyisocyanurate insulation board as a substrate because re-wetting of water-based adhesives could result in a delamination of paper-faced products.

COMMENTS

Be the first to comment. Please log in to leave a comment.