Self-adhering polymer-modified bituminous sheet underlayments enjoy widespread acceptance and use in the U.S. roofing industry. According to The 2005-06 NRCA Steep-slope Roofing Materials Guide, nine manufacturers produce 21 self-adhering polymer-modified bituminous sheet underlayment products.

NRCA and many roofing professionals recognize there are considerable differences among some self-adhering polymer-modified bituminous sheet underlayments. To better understand these differences, NRCA performed a limited analysis—including laboratory testing—of self-adhering polymer-modified bituminous sheet underlayments. The results of the analysis may surprise you.

Product usage

Self-adhering polymer-modified bituminous sheet underlayments offer considerable advantages over alternative means of providing waterproof membrane underlayments for steep-slope roof systems. For example, before the development and widespread acceptance of underlayments, underlayments for ice damming areas on steep-slope roof systems typically consisted of applying two layers of organic felt in solid troweled applications of roof cement. The use of self-adhering polymer-modified bituminous sheet underlayments for this application provides a substantially cleaner application in a single labor-saving application.

Also, self-adhering polymer-modified bituminous sheet underlayments are semi-flexible and well-suited for use as waterproof underlayments in steep-slope transition detail conditions, such as valleys and roof-to-wall flashings.

Applicable standards

The recognized U.S. product standard for self-adhering polymer-modified bituminous sheet underlayments is ASTM D1970, "Standard Specification for Self-Adhering Polymer Modified Bituminous Sheet Materials Used as Steep Roofing Underlayment for Ice Dam Protection." Within this standard, minimum product workmanship, finish and appearance; physical property; and packaging and marking requirements are provided.

ASTM D1970 is the minimum requirement for self-adhering polymer-modified bituminous sheet underlayments for code compliance in the current editions of the International Building Code (IBC), International Residential Code and NFPA 5000 Building Construction and Safety Code.

ICC ES Acceptance Criteria AC48, "Acceptance Criteria for Roof Underlayment for Severe Climate Areas," also can serve as a basis for code compliance. The International Code Council Evaluation Service (ICC ES) maintains these criteria as alternative criteria for code compliance.

For example, IBC Sec. 104.11-Alternative materials, design and methods of construction allows a building official to accept alternative materials provided the materials meet the code's intent. Self-adhering polymer-modified bituminous sheet underlayments that meet ICC ES AC48 comply with the code provided they are accepted specifically by a code official.

ICC ES AC48's requirements are similar to ASTM D1970 except AC48 contains several test method parameters and additional tests for water absorption, pliability and accelerated aging.

Sampling and testing

NRCA obtained full-roll samples of 11 self-adhering polymer-modified bituminous sheet underlayments. These rolls were provided from in-hand stock held in storage warehouses by NRCA technical committee members from across the U.S. The rolls were procured through typical roofing product distribution sources.

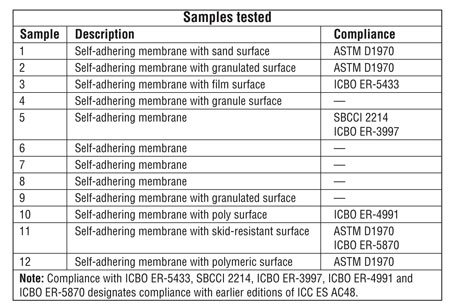

Figure 1: Descriptions and standard compliance labeling for self-adhering product samples

Descriptions of each product and sample number designations for testing purposes are provided in Figure 1. Products from Certainteed Corp., Valley Forge, Pa.; Elk Premium Building Products Inc., Dallas; GAF Materials Corp., Wayne, N.J.; Grace Construction Products, Cambridge, Mass.; Owens Corning, Toledo, Ohio; and Tamko Roofing Products, Joplin, Mo., were tested.

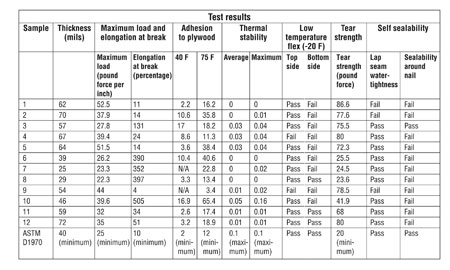

Figure 2: Physical property test results for self-adhering underlayment products

Laboratory testing was conducted according to ASTM D1970 by a recognized, respected testing laboratory. The results are provided in Figure 2.

Analyzing test results

Review of the test results reveals none of the self-adhering polymer-modified bituminous sheet underlayments tested fully comply with ASTM D1970's requirements. Only Samples 1, 2, 11 and 12 are represented by their manufacturers on their product package labeling as complying with ASTM D1970.

Samples 7 and 8 have maximum load values—23.3 pound force (lbf) per inch and 22.3 lbf per inch, respectively—below the 25-lbf-per-inch minimum requirement in ASTM D1970. Also, Sample 9 has a 4 percent elongation at break value, which is below the 10 percent minimum allowable value in ASTM D1970.

Samples 7 and 9 had no recordable peel strength adhesion values when tested at 40 F; these samples did not adhere to the test substrate. ASTM D1970 includes a 2-pounds-per-foot minimum value for peel strength adhesion value when tested at 40 F. When tested at 75 F, Sample 9 had a 3.4-pounds-per-foot minimum value—well below the 12-pounds-per-foot minimum allowable value in ASTM D1970. Sample 10 had a maximum flow value of 0.16 of an inch—exceeding the 0.1-inch maximum allowable value in ASTM D1970.

Only Samples 8, 11 and 12 passed ASTM D1970's low-temperature flexibility test at -20 F on the top side, bottom side or both. Samples 1, 2 and 9 failed the lap seam watertightness test.

All samples except Sample 3 failed ASTM D1970's nail sealability test. The samples' widespread failure of ASTM D1970's nail sealability test is of particular concern because this attribute of self-adhering polymer-modified bituminous sheet underlayments is a primary reason most roofing professionals use such products. And ASTM D1970's test method for nail sealability is considered by many to be not representative and actually less restrictive than field conditions for the product's use.

For example, ASTM International's laboratory test method provides for driving a roof nail into a specimen of self-adhering polymer-modified bituminous sheet underlayment adhered to a plywood substrate then tapping, or "backing out," the nail's pointed end to raise the nail head about 1/4 of an inch off the sheet's surface. The specimen then is subjected to a 5-inch head of water for three days. The process of backing out the nail in the test method is thought to enhance, or "gasket," the seal of the specimen to the nail's shank, which is not representative of actual field conditions.

Recommendations

Self-adhering polymer-modified bituminous sheet underlayments offer obvious advantages to alternative means of providing waterproof underlayments for steep-slope roof systems. However, NRCA's testing reveals significant differences among products.

NRCA recommends roofing professionals seek self-adhering polymer-modified bituminous sheet underlayments that comply with ASTM D1970. In addition to defining minimum physical and performance requirements, ASTM D1970 is a minimum requirement for building code compliance.

Also, NRCA encourages users of self-adhering polymer-modified bituminous sheet underlayments to not overly rely on the product's nail sealability feature because, as testing has shown, a product may not perform this function consistently. NRCA recommends minimum roof slope guidelines for steep-slope roofing products be followed as an effective and proven means of providing watertightness.

Finally, NRCA recommends ICC ES consider withdrawing its acceptance criteria AC48. Having both in the marketplace creates confusion about code compliance requirements. ASTM D1970 is a nationally recognized product standard that has been developed by ASTM International's consensus process, which includes individuals who are knowledgeable of the product and roofing application. If ICC ES desires to have the additional test methods' parameters in AC48 included in ASTM D1970, they should be submitted to the ASTM D1970 task group for consideration and appropriate action.

Mark S. Graham is NRCA's associate executive director of technical services.

COMMENTS

Be the first to comment. Please log in to leave a comment.