When it comes to asphalt-based roofing specifications, manufacturers often give their contractor customers more choices than they need. The asphalt roof system category itself contains many types, such as built-up, polymer-modified bitumen and hybrid roof systems. In addition, the number of FM Global (FM) and Underwriters Laboratories Inc. asphalt-based roofing approvals is staggering.

At some point, competitive pressures and the idea "it's all about choice" made specifying asphalt-based roofing materials more complex and costly than it needs to be. By taking a closer look at what's really needed based on deck type, fire and wind-uplift ratings, and other criteria, the asphalt roofing industry can create greater value by reducing costs across the entire supply chain. At the same time, manufacturers can make the choices less complex for their customers.

For example, imagine shopping for cereal at the local grocery store and finding 800 brands of cornflakes on the shelves. You would be faced with an almost impossible decision based on price, perceived quality and what your family prefers. Of course, this would never happen in the real world because retailers couldn't possibly afford to stock so many similar products.

But this is what is occurring in the roofing industry. Choice can be a good thing, but not when it threatens to confuse customers, complicates the sales process, and drives up costs for distributors and manufacturers. For any given roof system type, there may be hundreds of choices on the market, but a building owner is looking for just one cost-effective solution that meets his or her needs.

A kaleidoscope of choices

Asphalt roofing has been around for more than 150 years and continues to play a significant role in the commercial roofing market. The advantages of these systems, including long life, multi-ply redundancy and outstanding puncture resistance, are well-known to roofing contractors, architects and roof consultants.

However, a lot has changed during the past 40 years. The largest shift occurred during the single-ply revolution of the 1970s when dramatically higher oil prices pushed asphalt-based systems out of the commodity roofing markets.

Since then, the market share of asphalt-based commercial roofing has steadily decreased as a result of competition from less expensive single-ply membranes. What was once a majority of the low-slope roofing business a decade ago was just 18 percent in 2013, according to Malvern, Pa.-based Principia Consulting LLC's Commercial Roofing 2014, a research and market-update publication. As a result, the industry's asphalt-based infrastructure must support manufacturing and sales volumes that are three to four times what actually is needed.

In asphalt's heyday, polymer-modified bitumen and BUR manufacturers continually were coming out with new twists on product and system specifications to leapfrog and block out competitors. The focus was more about marketing prowess to get an advantage over competitors and less about what customers needed. The result was customers often were left confused and facing thousands of system combinations.

The sheer quantity of these products and systems now in a much smaller market has implications on many fronts. From my experience working for two manufacturing companies, I have counted 800 GAF asphalt roof systems and estimate 800-1,000 asphalt roof systems are available from each major manufacturer in the roofing industry. GAF customers, and even its salespeople, have expressed confusion with understanding so many roof system choices. From the manufacturing perspective, the cost of storing a variety of SKUs and maintaining code approvals for so many roof systems also is costly.

Even when a roofing contractor or specifier narrows the current choices to just one roof system type, he or she still is left with hundreds of systems from which to choose. In most cases, roofing contractors tend to default to the roof systems they know best while hundreds of other options are ignored.

The fact is many asphalt-based systems essentially perform the same function on a roof with subtle differences in performance or cost. In contrast, the TPO single-ply market, which is nearly twice the size of the asphaltic business, has about 75 percent fewer systems. Perhaps the limited number of TPO system options has helped the rapid growth of this technology?

The wide variety of products and systems also dramatically increases costs for distributors because they need to order and manage so many products. In addition, stocking a broad range of products will drive up costs that ultimately are passed on to customers. This makes asphalt-based systems less attractive from a cost-effective point of view.

Understanding customer needs

In any business, it's critical to understand customer needs, and the roofing business is no exception. If a customer is looking for proven, long-term performance and peace of mind, many roofing professionals continue to rely on asphaltic-based roof systems.

When choosing a roof system for any given building, there are several factors to consider, such as deck material, roof membrane type and insulation. There also are site-specific considerations: Is the building in an arid, dry climate; a warm, humid climate; or a cool, temperate climate? Is it in an area subject to hurricanes or significant hailstorms?

Next come building use considerations: Is the facility used for housing people (offices) or for manufacturing or storage (warehouses)? Does the building house sensitive, expensive or irreplaceable products or equipment? Or is it designed as a hospital, school or for government use?

Another consideration is roof system longevity and desired guarantee. A property owner who plans to sell the building in the near future may not want to spend the money on a long-term system and may not require a manufacturer's warranty. Some may opt for a 10-year warranty, while many customers are most comfortable with a 20-year, no dollar limit (NDL) warranty or longer.

There also are a number of other important considerations when specifying a new or replacement roof system, including the following:

Even with all these considerations, a customer doesn't need nearly as many of the asphalt-based products currently being offered, making it more difficult for him or her to understand why an asphalt-based roof system would be best for his or her building.

Now, let's take a look at roof warranties. Does the roofing industry need nearly 50 hot-applied asphalt systems that all provide the same 15-year warranty?

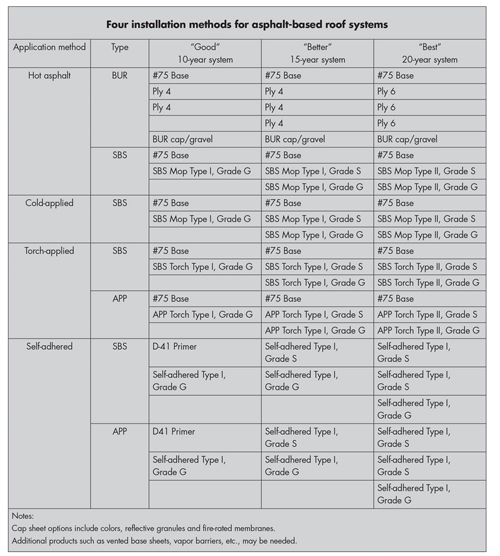

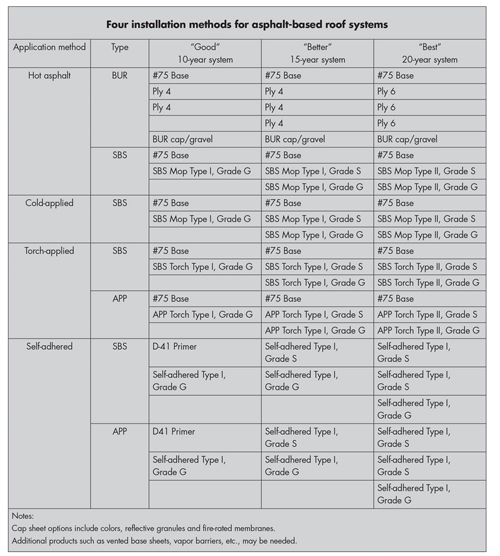

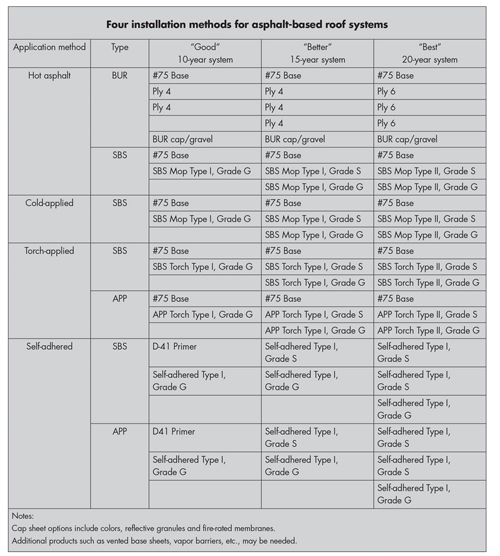

If we take the common good, better and best approach to marketing, customers can be satisfied with far fewer roof system choices than currently are being offered. Assume for a moment that a "good" system offers a 10-year warranty, a "better" system offers a 15-year warranty and a "best" system offers a 20-year warranty. Of course, there are systems that last longer and are guaranteed to last longer than 20 years.

However, a good, better or best marketing-classified roof system directly is related to its components and the application method. Asphalt-based roof systems can be torch-applied, self-adhering, or installed by adhering in hot asphalt or a cold-process adhesive. In some cases, the installation method will improve the performance or reduce the application cost. In other cases, the cost of labor, contractor preference or project circumstances can alter performance or cost. For example, a roofing contractor may prefer to use hot asphalt, but if a building is occupied by many people, he or she may choose not to use hot asphalt because of possible occupant concerns regarding fumes.

Type II membranes

Labor also is a crucial part of the cost equation. The more layers required, the more expensive it will be to install a roof system. If a contractor can offer his or her customer a 20-year NDL warranty using two ASTM D6163, "Standard Specification for Styrene Butadiene Styrene (SBS) Modified Bituminous Sheet Materials Using Glass Fiber Reinforcements," Type II polymer-modified bitumen membranes, why offer the current option of three Type I polymer-modified bitumen membranes? Clearly, two Type II membranes are more cost-effective than installing three Type I membranes.

Given all the considerations discussed so far, let's look at what really is needed for the asphalt roofing business. Figure 1 shows four installation methods for asphalt-based roof systems (it is not meant to represent a complete list of products). There still are variances that provide benefits, such as the flexibility of a polyester mat, the cost and dimensional stability of a fiberglass mat, or even the high performance of a dual, hybrid fiberglass/polyester mat that meets ASTM D6162, "Standard Specification for Styrene Butadiene Styrene (SBS) Modified Bituminous Sheet Materials Using a Combination of Polyester and Glass Fiber Reinforcements." These are important ways competitors differentiate themselves from other companies, but there certainly are opportunities for manufacturers to simplify their offerings to customers.

Figure 1: Four installation methods for asphalt-based roof systems

Figure 2 illustrates one way to meet customer needs more simply and at a reduced cost as a result of fewer roof system options. Figure 3 represents the actual products required to install the roof systems. Imagine what this straightforward line of products and systems could do to simplify the lives of roofing contractors, customers, specifiers, distributors and manufacturers.

A secondary benefit of this approach is it debunks the myth about the complexity of asphalt-based roof systems. A streamlined product offering can help show the next generation of roofing contractors that built-up, polymer-modified bitumen and hybrid roof systems are neither as difficult to specify nor as costly to install as may appear at first glance.

Figure 2: Illustration of one way to meet customers' needs more simply and at a reduced cost as a result of fewer roof system options.

Admittedly, limiting asphalt-based roofing choices from thousands of product combinations to hundreds of specifications likely will remove certain esoteric system combinations of which some roofing contractors have occasionally come to rely.

Let's consider another practical matter—specifically, the reality of "or equal" specifications and frequent roof system or component substitutions made by an architect or property owner. The change to a more manageable set of roofing choices should help mitigate these challenges in the specification process for a majority of roofing contractors. Fewer alternate bids, post-job conferences and product substitutions should result in less confusion and greater time and labor savings for all involved.

Figure 3: Actual products required to install roof systems

Other benefits, such as easier-to-understand roof system inspection and maintenance procedures; leaner product and technical literature requirements; simplified training of roof mechanics; improved profitability from longer production runs of fewer products; and quicker and clearer analyses of existing roof systems also should become apparent as asphalt-based roof choices are pared down to a practical level.

Focus on the customer

The bottom line is thousands of roofing products and/or roof system components have been introduced in the asphalt-based market solely to either meet or exceed the choices offered by competitors. Shouldn't we be focusing less on our competition and more on the value we can offer our customers? It's a question the asphalt-based roofing industry needs to answer, and it's one that has been put off or ignored for too long.

At GAF, we are taking the lead by reducing product SKUs to streamline offerings and simplify roof system choices. Doing so runs the risk of GAF being accused of not having a full product line, but we believe it is in our customers' best interests to not offer a dozen products that provide the same features, and we hope other manufacturers will follow. If manufacturers can successfully produce fewer SKUs, it will improve competitiveness, cost and profits for the asphalt roofing industry.

Lee Martucci is product manager, commercial roofing systems at GAF, Wayne, N.J.

COMMENTS

Be the first to comment. Please log in to leave a comment.