In 2009, I wrote about the development of algae-inhibiting surfacing granules for asphalt shingles and the then-available algae-resistant asphalt shingle products and associated warranty terms (see "The fight against algae," April 2009 issue). But the industry has evolved since then, and there have been some changes in the current algae-resistant shingle market and associated product warranty terms.

Dark stains

The dark stains noticeable on rooftops in many parts of the U.S. and Canada are accumulations of blue-green algae, single-cell organisms typically from the family Gloeocapsa. The stains are readily recognizable by their resemblance to black ink blots and appear darkest near the top of a roof and may thin out as they extend downslope on a roof's surface. Some severely affected roofs have dark stains from eave to peak.

Roofs are not the only locations where blue-green algae thrive in urban environments. Similar staining commonly is visible on stucco and limestone walls, limestone and marble columns, and staircases. There is no evidence blue-green algae harms asphalt shingles, and asphalt shingle manufacturers consider it an aesthetic issue.

To grow and spread, blue-green algae require water, air, sunlight and carbon from inorganic sources. Limestone fillers in asphalt shingles dissolve in dew as shingles age and provide a source of carbonate ions blue-green algae require to carry out photosynthesis. Gloeocapsa cells are surrounded by a gelatinous outer sheath that helps them adhere to surfaces and develops protective dark coloration when directly exposed to sunlight. Blue-green algae reproduce by releasing airborne spores that readily spread the infestation to nearby surfaces.

Algae-inhibiting granules

I asked nine asphalt shingle manufacturers and two suppliers of algae-inhibiting granules whether there have been any notable technological developments or new solutions for asphalt shingles since my previous article. Six asphalt shingle manufacturers and the two suppliers—3M Industrial Mineral Products Division (3M), St. Paul, Minn., and Specialty Granules Inc. (SGI), Hagerstown, Md.—indicated the algae-inhibiting technology for asphalt shingles has not changed since 2009. The same algae-inhibiting top-surfacing granules that were used during 2009 continue to be used in products currently manufactured.

According to 3M, which originally developed the technology, the algae-inhibiting top-surfacing granules remain a proven solution that is robust. 3M currently offers four copper granule colors ranging from a light grey to black. 3M supplies surfacing granules to several North American roofing manufacturers.

Some asphalt shingle manufacturers partner with 3M to offer its ScotchgardTM Protector feature with their products. To use the Scotchgard Protector brand, 3M contractually requires asphalt shingle manufacturers to meet three key conditions: 3M copper-bearing granules must make up a minimum of 10 percent of top-surfacing granule blend; 3M copper-bearing granules must be uniformly distributed on the shingles, including hip and ridge covers; and a third-party laboratory must test product samples from every production run to verify 3M copper-bearing granule content and uniform distribution. 3M indicates the laboratory quality-assurance method uses X-ray fluorescence spectroscopy to determine the amount and distribution of elemental copper on the shingles' exposed surfaces.

SGI (formerly ISP Minerals) uses similar technology. Currently, it offers algae-inhibiting granules in three colors. SGI supplies surfacing granules to GAF, Parsippany, N.J., roofing manufacturing plants and other roofing manufacturers.

Two asphalt shingle manufacturers have developed their own copper-bearing algae-inhibiting granules: CertainTeed Corp., Valley Forge, Pa., and IKO Industries Ltd., Brampton, Ontario. IKO Industries manufactures a black algae-inhibiting granule. CertainTeed declined to provide information about its algae-inhibiting granules.

At a glance, algae-inhibiting granules are indistinguishable from common ceramic-coated mineral granules used as the bulk of top-surfacing material in asphalt shingles, stone-coated metal shingles and granule-surfaced polymer-modified bitumen cap sheets. Algae-inhibiting granules undergo additional manufacturing steps that add a copper-bearing layer before the pigmented coating is deposited. The copper-bearing granules are intended for blending with common top-surfacing granules and provide for a slow release of algae-inhibiting copper ions throughout the service life of an asphalt shingle roof system.

Once algae-resistant asphalt shingles are exposed to the weather, small quantities of algae-inhibiting copper ions are released. Rooftop moisture—primarily dew—acts as a medium for the distribution of the algae inhibitor on roof surfaces. This mechanism has a limited effective radius. Copper granules need to be distributed uniformly and present in sufficient amounts to effectively prevent algae growth. Areas where algae-resistant granule loading is too low or the granules too scattered may develop stains.

Owens Corning, Toledo, Ohio, and TAMKO Building Products Inc., Joplin, Mo., declined to address questions about algae-resistant technology development and use in their products and indicated they consider it confidential information. Building Products of Canada Corp., Calgary, Alberta, did not provide a response.

Does it work?

3M indicates its Algae BlockTM (3M replaced Algae Block with the Scotchgard Protector label in 2003) copper-bearing granules first were used in shingles available during the early 1990s. A promotional piece from Malarkey Roofing Products, Portland, Ore., states the company was first to market a 3M Algae Block shingle in 1994.

3M indicates its solution to algae staining is backed by decades of science and development and has proved to be robust. The company uses outdoor-weathering test decks in locations where algae staining is common to evaluate its technology. 3M has operated an outdoor-weathering facility in the Houston area since 1937.

A former 3M scientist wrote the following about why Houston was chosen: "Scientists at the time chose Houston after a long study, not only for its high temperature and solar radiation alone, but this combined with extremely high humidity and drastic temperature changes which occur with flash rainstorms makes it an ideal location to study building material products."

3M offers weathering services at the Houston site to its customers. Reportedly, there are more than 3,000 test panels undergoing natural weathering exposure at the site (see photo).

Several asphalt shingle manufacturers stated they monitor algae-resistant performance of products exposed on weathering decks and while in service. One manufacturer indicated 3M provides progress reports regarding the performance of its products exposed at the 3M weathering site. Another manufacturer stated products monitored on roofs in Florida and Hawaii remained stain-free after 15 years in service.

3M and Owens Corning have co-developed a laboratory test method for shingles that use 3M's algae-inhibiting technology. In 2007, 3M took up an effort at ASTM International Committee D08 on Roofing and Waterproofing to use it as basis for developing a standard laboratory practice for evaluating the efficacy of asphalt shingles' algae resistance. By late 2009, it was apparent the interested parties were not going to reach an agreement, and 3M dropped the effort. The company says it continues to use the test method, and some of its customers have indicated they use it, as well.

Asphalt shingles with current algae-resistant technology have a record of more than 20 years of successful performance in service, according to supplier claims. Evidence that would allow independent verification of these claims has not been released to the public. Also, no consensus standard is available to independently evaluate or rate product performance in a laboratory setting.

Varied promotional approaches

If the technology is known to be reliable and has widely been used for many years, it is reasonable to expect it is valued by manufacturers for its marketing potential. Have asphalt shingle manufacturers made effective use of it with their customers? If the question is to be answered based on marketing materials available to contractors and consumers, the approaches used vary among manufacturers.

Atlas Roofing Corp., Atlanta; Malarkey Roofing Products; and PABCO Roofing Products, Tacoma, Wash., market asphalt shingles featuring 3M's Scotchgard Protector brand. The Scotchgard Protector logo is prominently displayed in printed marketing materials and on websites alongside promotional text describing the feature and its benefits. Product web pages include links to web content specifically addressing the staining issue and 3M's solution for asphalt shingles. The message delivered by different promotional pieces consistently hits on talking points that explain the benefits of installing asphalt shingles with Scotchgard Protector.

These materials indicate 3M is involved with helping manufacturers share information with installers and consumers. For example, Atlas Roofing, which introduced Scotchgard Protector products about six years ago, has partnered with 3M to launch a Shingle Sales Specialist Training Program that instructs roofing contractors how to educate roofing customers regarding the benefits of installing 3M Scotchgard Protector shingles to sell more jobs. 3M credits the growth of its algae-inhibiting granule business in part to greater consumer awareness and resulting demand for an effective solution.

In addition to promotional materials, technical resources addressing algae staining are available from these manufacturers. A PABCO Roofing Products technical bulletin, "Recommended Maintenance Practices," has recommendations for cleaning algae-stained asphalt shingles. PABCO Roofing Products recommends applying an equal-parts solution of chlorine bleach and water and thoroughly rinsing with low-pressure water after a 15- to 20-minute soak. The PABCO Roofing Products bulletin does not recommend using any other cleaning methods for algae on asphalt shingles.

A glossary available in the technical resources section on Malarkey Roofing Products' website includes entries that explain the origin of algae staining with a link to a page where 3M provides information about the working principle behind its solution.

CertainTeed and GAF are two manufacturers that internally source algae-inhibiting granules. Both companies have promotional materials to educate end-users about the benefits of their algae-resistant shingles. This content is available from CertainTeed's and GAF's consumer-facing websites but are not as easily identifiable as compared with materials promoting the Scotchgard Protector-branded products.

CertainTeed has published a brochure promoting shingles with its StreakFighter® algae-resistant feature. The brochure describes a technology similar to 3M's technology that provides for gradual long-term release of algae-inhibiting copper ions from specialty granules uniformly distributed over the surface of a shingle.

GAF Technical Advisory Bulletin TAB-R 2011-102, "Algae Staining On Shingled Roof Surfaces," explains how algae staining develops, promotes GAF shingles with a StainGuard® feature based on algae-inhibiting granule technology and offers recommendations for cleaning. GAF's recommended cleaning solution is four parts water, one part bleach and about 1/16 part trisodium phosphate (TSP) or an acceptable phosphate-free substitute. TSP is an effective cleaning agent, but runoff may cause damage to water ecosystems when it enters lakes and rivers.

Also, a GAF Steep Slope Pro Field Guide addresses algae stains on asphalt shingles. It recommends against re-covering algae-covered shingles because the new shingles will likely develop algae stains. The guide also explains the available solutions, including installing GAF StainGuard shingles, and cleaning and installing "zinc moss preventer." (This can be confusing because it mentions moss and fungus in a section labeled "Algae Stains.")

The website for Owens Corning roofing products has a brief explanation of algae staining. It indicates Owens Corning provides limited warranty coverage for algae resistance for some of its asphalt shingles. The web page does not state what algae-inhibiting technology is used in Owens Corning asphalt shingles. The same website has a Hip and Ridge Technical White Paper PDF that makes a reference to hip and ridge shingles with "a special treatment added to resist roof discoloration due to algae growth."

IKO Industries' website offers promotional pieces for each asphalt shingle product available for download. These fold-outs note most products are algae-resistant. A note in fine print on each information sheet and brochure indicates algae-resistant shingles contain "a preservative to help inhibit discoloration by algae."

Asphalt shingle product catalogues, "BP Roofing Guide (East)" and "BP Roofing Guide (West)," dated May 2015 available for download from Building Products of Canada's website note warranty coverage against blue-green algae now is included as part of the company's asphalt shingle warranty.

TAMKO Building Products' asphalt shingle promotional materials contain no references to an algae-inhibiting product feature. Some promotional sheets make mention of "A 10-year Algae Relief—Algae Cleaning Limited Warranty that provides for cleaning of discoloration caused by certain algae growth."

My survey of promotional content available from asphalt shingle manufacturers' consumer-facing websites revealed manufacturers place varying levels of value on using algae resistance for product marketing. Manufacturers that use 3M's readily recognizable brand or brand their own algae-resistant technology offer more educational and promotional resources intended for installers and consumers. Little to no technical resources and limited promotional information regarding algae resistance is available from the remaining manufacturers. Two manufacturers only provide end-users with warranty information related to algae discoloration—a tacit admission this is what the marketplace expects.

ARMA weighs in

The Asphalt Roofing Manufacturers Association (ARMA) is a trade association representing North America's asphalt roofing manufacturers and its raw material suppliers. ARMA's stated mission is to advocate and advance the interests of the asphalt roofing industry. All asphalt shingle manufacturers surveyed for this article are ARMA members.

"Algae Discoloration of Roofs" is a technical bulletin available from ARMA. The original version was published in 1989 and has been revised several times; the current version is dated June 2014. The bulletin discusses the root cause of the algae-staining issue and contributing factors such as a warm, humid climate and light-colored roof surfaces. It provides a method for lightening the stains using a cleaning solution. The current document calls for a one-to-one mixture of household bleach and water to be dispersed on the roof and allowed to soak for up to 20 minutes. Then, the cleaning solution is to be rinsed by gently spraying the surface with water. ARMA warns against scrubbing the stains and using pressure-washing systems as damage to shingles may result. ARMA warns cleaning only is temporarily effective against algae staining and may have to be repeated. For a long-term solution, ARMA points to asphalt shingle products specifically designed to inhibit algae growth for extended periods of time.

In November 2016, ARMA produced a video, "Your Guide to Algae Discoloration," which is available on YouTube. The video is based on ARMA's technical bulletin and intended for homeowners. It provides a general explanation of algae staining on asphalt shingles and advice for addressing it. The video provides sensible general advice and refers homeowners to individual manufacturers for specifics of cleaning formulas and warranty requirements. The voiceover also advises some manufacturers have algae-resistant shingles available. This part is inconsistent with the message coming directly from North American asphalt shingle manufacturers whose product warranties indicate every manufacturer offers asphalt shingle products with warranty coverage against algae discoloration.

Warranty terms

Asphalt shingle warranty documents are best described as a convoluted mess. Warranty language is prepared by attorneys, intended to protect manufacturers and is reactive rather than proactive. Manufacturers regularly review and update the language of asphalt shingle limited warranties. This process can materially alter the warranty terms from one revision to the next.

It is typical for an asphalt shingle warranty document to grow in length over time as new sections and revisions are added when attorneys develop new provisions designed to limit or remove coverage for conditions responsible for the most recent rash of warranty claims. Generally, asphalt shingle product warranties provide remedies for claims resulting from manufacturing defects.

Consumers should carefully examine asphalt shingle warranty documents. This will help avoid misunderstandings later, especially as there may be uncommon or unexpected clauses included in some warranties. For example, one manufacturer's warranty states its algae-resistance warranty only is valid when the asphalt shingles in question contain a manufacturing defect that has resulted in a leak.

Typically, provisions that address coverage for claims resulting from staining caused by blue-green algae are in a separate section of an asphalt shingle product warranty document and provide a warranty coverage length that is shorter than the period applicable to claims resulting from manufacturing defects. Asphalt shingle algae-resistance warranty lengths currently available are mostly unchanged from 2009. Depending on manufacturer and product, they range from five to 20 years.

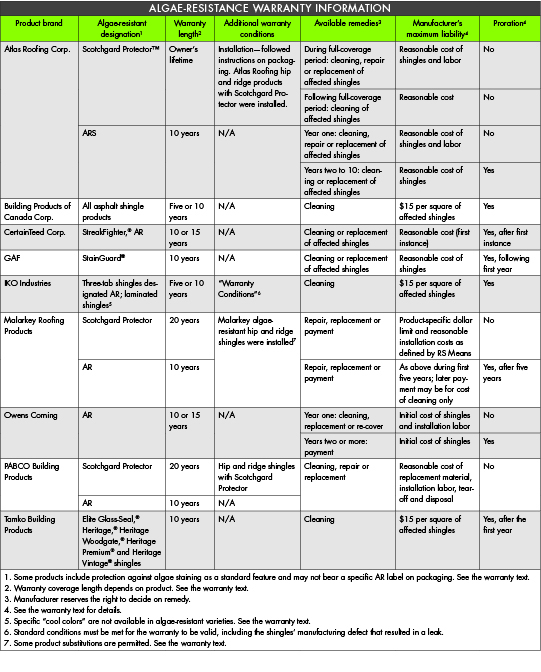

The figure provides a comparison of algae-resistance warranties currently available from North American asphalt shingle manufacturers. Following are the highlights.

Twenty-year algae-resistance warranties are available for Atlas Roofing, Malarkey Roofing Products and PABCO Roofing Products asphalt shingles with Scotchgard Protector. Installing Scotchgard Protector hip and ridge shingles is required. The warranty terms indicate manufacturers will pay for replacement or cleaning of shingles that exhibit discoloration as a result of algae, including the cost of shingles and installation labor. These benefits are not prorated though the manufacturers reserve the right to determine the remedy. Atlas Roofing's warranty indicates after 10 years the sole available remedy is payment for cleaning.

Atlas Roofing, Malarkey Roofing Products and PABCO Roofing Products also market asphalt shingles labeled "AR" and "ARS" with shorter algae-resistance warranty lengths that range from five to 12 years depending on manufacturer and product. Products in this category are manufactured with 3M copper-bearing granules used in lower amounts than required for Scotchgard Protector-labeled products, according to the manufacturers. With these products, algae-resistance warranty terms vary by manufacturer. PABCO Roofing Products provides the same terms as its Scotchgard Protector products except for a period of 10 years. Atlas Roofing and Malarkey Roofing Products provide prorated benefits, and their available remedies vary.

For CertainTeed StreakFighter, GAF StainGuard and Owens Corning AR products, the manufacturers indicate algae-resistance warranty lengths from 10 to 15 years, depending on manufacturer and product, and provide prorated benefits after the first year or first claim occurrence. Specifics of what the warranty promises to pay for vary by manufacturer.

Building Products of Canada and TAMKO Building Products do not use brand names or other labels to designate algae-resistant asphalt shingle products in promotional materials and product packaging. IKO Industries uses AR for some of its three-tab asphalt shingles but has no similar designation for any of its other products that are marketed as algae-resistant. These manufacturers indicate algae-resistance warranty lengths of five to 10 years, depending on manufacturer and product, and payment of prorated costs for cleaning algae-stained shingles. All three specify a flat base rate of $15 per square. The same rate was specified by IKO Industries and TAMKO Building Products warranties in effect in 2009.

NRCA recommendations

NRCA encourages roofing contractors who promote algae-resistant asphalt shingles as part of their sales processes to press manufacturers to provide objective evidence the feature works. Contractors who take advantage of asphalt shingle manufacturers' business support services or participate in manufacturer-sponsored sales and applicator training programs should use it as an opportunity to challenge a manufacturer to provide the information.

With respect to selection of construction materials and methods, NRCA has maintained a history of successful past performance is the best indicator of future performance. When selecting algae-resistant asphalt shingle products, NRCA recommends roofing contractors and consumers consider products with histories of proven performance.

Maciek Rupar is an NRCA director of technical services.

COMMENTS

Be the first to comment. Please log in to leave a comment.