The phrase "green and growing" appropriately describes a segment of the roofing industry that is demonstrating growth and opportunity during challenging economic times: cool roof coatings.

This is partly because there is a continuing emphasis on all things "green," or sustainable. For example, Secretary of Energy Steven Chu recently spoke about the energy-saving benefits of white reflective roof coatings, and in late September, former Vice President Al Gore helped apply white reflective roof coating to a roof in New York and spoke about such coatings' heat island mitigation benefits.

Reflective roof coatings are considered sustainable because they help extend the service lives of existing roof substrates, provide energy savings for buildings and positively affect the environment in various ways.

In addition, building owners, government leaders and consumers are searching for ways to demonstrate they are environmentally conscious by saving energy and reducing their carbon footprints. The exposure and excitement surrounding cool roof coatings' sustainability benefits present an opportunity for roofing contractors to expand their businesses, meet the needs of sustainability-conscious consumers and perhaps improve their companies' revenues in the process.

Extending roof system life

It is understood and accepted that black and other dark roof surfaces absorb much of the sun's incident infrared radiation and become hot and white and light-colored roof surfaces reflect much of the sun's rays, emit absorbed heat and stay dramatically cooler—as much as 60 degrees Fahrenheit lower on clear summer days.

Roof coatings manufacturers long have touted the benefits of white and light-colored reflective roof coatings for extending the service lives of dark roof substrates to which they are applied. A reflective roof coating acts as a protective barrier on a roof substrate by shielding it from damaging ultraviolet rays that initiate the chemical breakdown of roof substrates, resisting erosion caused by weather and keeping the roof system's temperature lower to slow the substrate's rate of aging.

Reapplying a reflective coating every 15 to 20 years may help a roof system continue to provide benefits for several decades. Keep in mind, I am not referring to an asphaltic coating that may last only five to 10 years. Coating technologies based on acrylic, polyurethane and silicone resins have been used for 25 years and, when properly applied at recommended thicknesses, have service lives of 15 to 25 years.

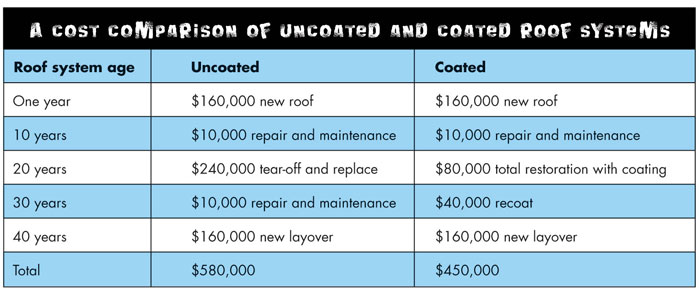

The figure compares the construction, maintenance and repair costs during a 40-year time period of a traditional black roof system with a roof system featuring a reflective white coating.

As the figure demonstrates, keeping an existing roof system in place and protecting it by applying a reflective coating can provide a significant financial return to the building owner and keep a fair amount of roofing material out of landfills. In addition to providing potential energy savings, assisting with mitigating the heat island effect, and helping increase efficiency and longevity of roof-mounted HVAC units, applying a coating helps extend roof substrate and system service life.

This chart compares the costs of uncoated and coated roof systems.

Energy savings

Serious discussion about the energy-saving benefits of white and light-colored reflective roof coatings applied to traditional black roof surfaces began a dozen or more years ago as roofing materials manufacturers and contractors began sharing anecdotal evidence of energy savings from various roof coating applications.

Then, several things happened:

Reflective roof coatings' effects on dark roof systems and their surface temperatures vary widely depending on roof assembly type, building location, climate, and building operating systems for cooling and heating, etc. During the past several years, rooftop conditions documented by ORNL, LBNL and ERSystems Inc., Rockford, Minn., among others, have shown:

Also, within the past few years, LBNL has developed simulations demonstrating how cool roof surfaces affect heat islands.

In "Potential Benefits of Cool Roofs on Commercial Buildings: Conserving Energy, Saving Money, and Reducing Emissions of Greenhouse Gases and Air Pollutants," LBNL scientists Hashem Akbari and Ronnen Levinson estimate if roofs on 80 percent of air-conditioned commercial buildings in the U.S. were coated to qualify as cool roofs (a conservative 55 percent aged solar reflectance), the buildings' owners would save more than 10,000 gigawatt hours of energy annually valued at about $725 million. These energy savings also would result in an annual reduction of more than 6 megatons of carbon dioxide production, which is equivalent to the carbon dioxide emissions of about 1.25 million automobiles.

The same LBNL study estimates dramatic reductions in nitrogen oxides, sulfur dioxide and mercury emissions. The temperature reduction within urban areas, as well as the reduction of greenhouse gases and other pollutants in the form of smog, could be dramatic.

Common concerns

Although reflective roof coatings' popularity has grown during the past 10 years, roofing professionals have raised several questions regarding coatings' long-term performance. Three of the most common concerns are coating durability, soiling of white and light-colored coating surfaces and the resultant loss of solar reflectance, and climate limitations of energy savings related to cool roof coatings. (Using cool roof coatings in cool climates produces a "heating penalty"—a dark, heat-absorbing roof surface is thought to be advantageous during heating season.)

Durability

There are many factors that affect a coating's long-term performance and durability. A coating applicator first must select a product that will adhere well to a given roof substrate. If the coating does not adhere well to the roof substrate, nothing else matters. Adhesion depends on the appropriateness of a surface/substrate for a coating, how well a surface is prepared for a coating and the application technique.

A well-formulated coating (one formulated to its respective ASTM International performance standard) properly selected for a specific roof surface and properly applied should perform for 15 years or more. (Fifteen years is not necessarily the minimum, but a well-formulated product—as described in The NRCA Guide to Roof Coatings, Second Edition—should be designed to perform to that level in ordinary conditions.) Then, the roof can be recoated with the same coating type with minimal surface preparation, extending the coating's life.

Soiling

All coatings and roof surfaces accumulate dirt over time. In fact, dark roof surfaces may accumulate dirt and increase their solar reflectances. Likewise, white and light-colored roof surfaces tend to accumulate dirt and have a corresponding loss of solar reflectance over time.

It is well-documented and well-known that most roof coatings absorb dirt quickly when they are fresh and their initial solar reflectance of 0.85 to 0.90 drops to 0.70 to 0.75 during the first few months of exposure, leveling off at 0.60 to 0.70 after the first year (a loss of 25 to 30 percent). As a result, energy savings calculations related to white and light-colored coated roofs typically are based on a conservative aged solar reflectance of 0.55.

One of the more exciting recent developments within the roof coatings industry has been the introduction of finish coats, or topcoats, that stay clean and highly reflective for extended time periods. They are based on new emulsion-based, low-volatile organic compound polyvinylidene fluoride fluoropolymer technology.

Three-year aged exposure studies conducted by ERSystems of its ReflectiClean coating indicate the coating will retain a total solar reflectance of more than 0.75 for three to seven years. This may translate into energy savings 25 to 45 percent greater than could be realized with a coating that soils to an aged solar reflectance of 0.55.

In addition to excellent color and reflectivity retention, these new fluoropolymer finish coats demonstrate excellent durability and weathering, which means the time period between recoats may be extended and provide additional cost savings over time.

Cool climates

Highly reflective cool roofs are an obvious choice in the cooling-dominated Southern and Southwestern U.S. It is not surprising some people have purported cool roofs are disadvantageous in heating-dominated states where roofs already are cool for several months each year. But you must consider the cooling energy savings against the heating energy penalty for each building individually to arrive at an overall energy cost total.

Surprisingly, a significant body of data is being developed to document cool reflective roof systems' advantages on average even in cold, heating-dominated states, such as Minnesota.

Data gathered near Minneapolis by ERSystems indicates modest annual energy savings from reflective roof surfaces have been reinforced by Akbari and Levinson's study. Researchers simulated the potential effects of applying cool roof technology in place of traditional dark commercial roof systems in 236 cities throughout the U.S. LBNL found cool roofs generated more cooling energy savings than an increase in heating energy penalty in every state, including Minnesota and even most of Alaska.

Key to this study were assumptions made down to the local building inventories, including insulation levels of old (pre-1980) and newer buildings, the solar reflectance of aged roof surfaces, local climate conditions, and local energy sources and prices for cooling and heating. The study used the DOE-2.1E building energy model for calculations.

The heating penalty of reflective roofs in northern climates is minimized by several factors. Winter in northern climates is characterized by shorter days with more clouds and a lower angle of solar incidence. Even a dark roof may be white when covered with snow for much of winter providing no thermal advantage to the building. Different fuel sources are used for heating and cooling (coal and natural gas versus electricity) in most northern states with dramatic differences in cost. The DOE-2.1E model considers all these factors when generating the results.

Your opportunities

It is obvious cool roof coatings are a timely concept. The technologies are valid; the energy savings are documented; and the environmental benefits are real. Most important, receptivity by building owners, architects and roofing contractors to the energy- and environmental-related benefits is high.

Adding roof coatings to your roof application portfolio can greatly benefit your company. For one thing, you may expand your revenue base through your present customer base. Contact customers whose roofs you have installed during the past five to 25 years, and demonstrate the benefits of applying highly reflective coatings. Also, discuss potential government/tax incentives for energy-related improvements and demonstrate potential savings over time.

Remember, overhead costs to begin applying coatings are relatively low and some applicator training may be necessary, but profit potential is significant.

To get started, you may want to contact one or more manufacturing members of the Reflective Roof Coatings Institute. A roof coatings manufacturer should be able to help you with initial product and equipment training, on-site assistance, energy savings proposals and bid packages. The NRCA Guide to Roof Coatings, Second Edition also is an excellent resource for initial training and education of your employees.

If you want to add a sustainable offering to your business to meet your customers' needs, consider highly reflective roof coating applications. Extend the service lives of existing roof systems, save energy, provide myriad additional environmental benefits—and strengthen your business at the same time.

Jim Leonard is former president of the Reflective Roof Coatings Institute and founder of ERSystems Inc. and Prairie Technologies, Rockford, Minn.

COMMENTS

Be the first to comment. Please log in to leave a comment.