NRCA's EnergyWise Roof Calculator Online is a web-based application that provides a graphical method of constructing roof assemblies to evaluate thermal performance and estimated energy costs under normal operating conditions. Developed in 2007, EnergyWise Roof Calculator Online has been updated to include information from the most recent versions of the International Code Council's International Energy Conservation Code (IECC); the International Green Construction Code (IgCC); and ASHRAE Standard 90.1, "Energy Standard for Buildings Except Low-Rise Residential Buildings" (ASHRAE 90.1).

In addition, NRCA has included revised minimum long-term thermal resistance (LTTR) values and its latest recommendations for minimum R-values for polyisocyanurate insulation in the application. This most recent update also offers a new feature—the application now can determine the temperature gradient through a roof assembly and present the information graphically on a report. Users will find this feature beneficial when evaluating a vapor retarder's effectiveness.

Background

EnergyWise Roof Calculator Online is a free, web-based application that provides a graphical method of constructing a roof assembly to determine the overall R-value; the minimum R-value requirements for a selected code or standard; and estimated energy costs attributed to a roof assembly under normal operating conditions.

In 2007, the online version launched and has been updated throughout the years to incorporate the latest energy codes and standards. With this most recent update, the application now includes minimum R-value requirements for roof assemblies from the 2015 versions of IECC and IgCC and the 2013 version of ASHRAE 90.1. EnergyWise Roof Calculator Online addresses the following codes and standards:

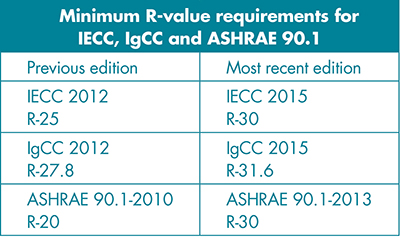

Minimum R-values on the rise

Designers should note the latest editions of IECC, IgCC and ASHRAE 90.1 may require higher minimum R-value requirements than their respective previous editions. To illustrate this, Figure 1 compares the minimum R-value requirements according to the previous and most recent editions of IECC, IgCC and ASHRAE 90.1 for an office building in Climate Zone 5 where the insulation is located above the roof deck.

Figure 1: Minimum R-value requirements for roof assemblies where the insulation is located above the roof deck |

R-value and LTTR

Users familiar with the EnergyWise Roof Calculator Online know the application includes R-values and LTTR values for polyisocyanurate insulation. In previous updates, R-values were revised to reflect changes to NRCA recommendations. With this update, not only have the R-values changed but the LTTR values have changed, as well.

As of January 2016, NRCA recommends designers use a design R-value of 5.0 per inch thickness for polyisocyanurate insulation in all climates. Previous recommendations called for an R-value of 5.0 in predominant heating-climate conditions and 5.6 in predominant cooling-climate conditions. (For background information about this revised recommendation, see NRCA's Industry Issue Update, "New polyisocyanurate R-values," January 2016.)

Additionally, U.S. polyisocyanurate insulation manufacturers began reporting LTTR values based on updated and revised test methods. As a result, LTTR values are less than values previously used. For example, the current design LTTR value for 1-inch-thick polyisocyanurate is 5.6 compared with the previous value of 6.0. The LTTR values used in EnergyWise Roof Calculator Online reflect these reduced values.

Users have the option to choose between R-value and LTTR values, but keep in mind NRCA does not consider LTTR use to be appropriate for roof system design purposes when actual in-service R-values can be important aspects of roof system and whole building performance.

A new feature

NRCA's Technical Services Section often receives telephone calls regarding condensation issues. Most of the concerns relate to vapor retarder design and, more specifically, how to confirm whether a vapor retarder will be effective.

A commonly used method to determine vapor retarder effectiveness is to simply calculate the temperature at the vapor retarder level and compare it with the design dew point temperature. The temperature at the vapor retarder must be warmer than the dew point temperature to prevent condensation. The previous version of EnergyWise Roof Calculator Online performed these temperature calculations and presented the results in a report.

However, based on feedback NRCA was receiving, it became evident there still is some confusion regarding vapor retarder concepts and calculations. To address this, NRCA added a new feature that provides users with the thermal gradient calculations and a graphic representation of temperature distribution through a proposed roof assembly. This information is presented in a report a user can generate.

Determining heat loss

During winter, warm interior air will cool as it passes through or across a roof assembly. Because every building material has distinct thermal-resistance properties, the rate at which the air cools depends on the material it is passing through.

The fundamental formula to determine heat loss, or temperature drop, at each material within a roof assembly is:

These temperature changes are referred to as temperature gradient. The temperature calculated for each material can be plotted on a roof assembly diagram to illustrate heat loss.

Following is an example demonstrating the "behind the scenes" heat-loss calculations in the EnergyWise Roof Calculator Online application.

Example

For a textile manufacturing plant located in Minneapolis, calculate the temperature gradient through a roof assembly composed of the following materials:

For this example, the following climate information and design temperature values are used:

A user will input the winter interior design dry bulb temperature and interior design relative humidity value. These can come from the building's HVAC system designer or, if it is an existing building, a knowledgeable building maintenance engineer or whoever maintains the building's HVAC and mechanical control systems.

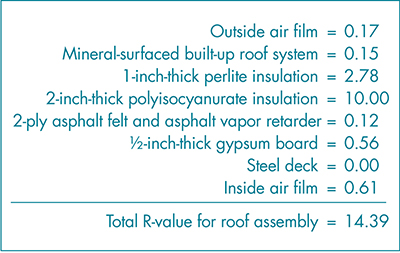

Figure 2: Total R-value of an overall roof assembly |

The winter exterior design dry bulb temperature automatically is provided in the application. It is based on the climate county or region the user selects. If more specific information is desired, the default value can be overridden. Values can be found in Chapter 14—Climatic Design Information of the ASHRAE Handbook—Fundamentals or by researching historical climatic data.

The overall R-value of a roof assembly also needs to be calculated. See Figure 2 for the R-values used in this example to determine the total R-value for the overall roof assembly.

EnergyWise Roof Calculator Online provides default R-values for various materials; however, users can override these values. Thermal properties of common building materials and air films can be found in Chapter 26—Heat, Air, and Moisture Control in Building Assemblies—Material Properties in the ASHRAE Handbook—Fundamentals or obtained from manufacturers.

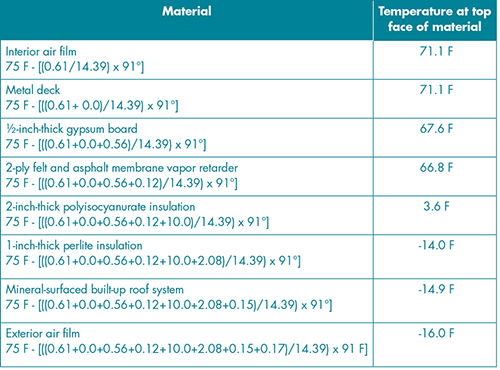

Using this information, the temperature at each material can be calculated using the following fundamental heat-loss formula:

See Figure 3 for heat-loss calculations for the example roof assembly.

Figure 3: Heat-loss calculations for the example roof assembly |

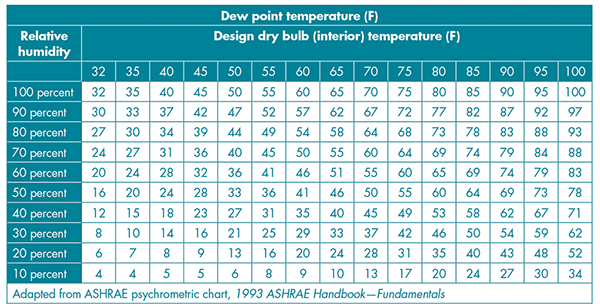

Finally, the dew point temperature is determined. EnergyWise Roof Calculator Online uses a simplified version of the ASHRAE psychometric chart (see Figure 4). The dew point temperature is at the intersection of the design dry bulb temperature column and the relative humidity row.

As previously mentioned, the interior design conditions are:

Figure 4: EnergyWise Roof Calculator Online uses a simplified version of ASHRAE’s psychometric chart |

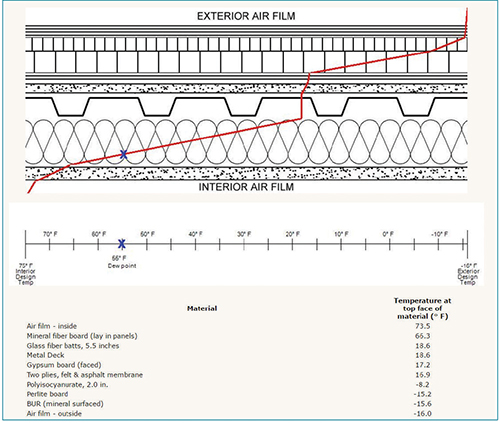

EnergyWise Roof Calculator Online takes the results and plots the temperature gradient values for each material on a roof assembly drawing. It also locates the dew point temperature value on the temperature gradient line. See Figure 5 for the graphic illustration EnergyWise Roof Calculator Online will produce for this example.

Things to note

The graphical method is a simplified procedure using theoretical constant values. Actual relative humidity and dew point temperature values constantly are changing in normal building environments as the ambient temperature and/or water vapor pressure in the air change. This method is just one way to determine whether the vapor retarder will perform its intended function. Roof system designers are encouraged to further substantiate their analyses by using other methods.

Figure 5: Temperature gradient through the example roof assembly. For this example, the dew point temperature falls within the insulation that is placed above the vapor retarder, so the vapor retarder should be effective. |

Additionally, this example and discussion did not address the guidelines for how to determine whether a roof assembly needs a vapor retarder. Readers are encouraged to refer to Chapter 2—Condensation Control for Low-slope Roof Systems of The NRCA Roofing Manual: Architectural Metal Flashings, Condensation and Air Leakage Control, and Reroofing—2014 for additional information. This chapter was updated in July to include a discussion about the temperature gradient method. The most current edition of the 2014 manual is available for download at www.nrca.net/store. (The downloaded document is free for NRCA members.)

Give it a try

EnergyWise Roof Calculator Online continually is updated to ensure it references the most recent energy codes and standards' requirements and reflects NRCA's recommendations for best roofing practices. Visit energywise.nrca.net and give it a try.

Joan Crowe, AIA, is a former NRCA director of technical services.

COMMENTS

Be the first to comment. Please log in to leave a comment.