Metal is a rigid material, and as with all rigid materials, metal expands and contracts when temperatures change. Expansion and contraction factors often are overlooked or regarded as insignificant in metal roof system design and construction. Metal roof systems can be the least forgiving of all roof systems if provisions for expansion and contraction are neglected.

For example, expansion and contraction can cause metal components to become distorted and possibly loosen from a substrate. Not correctly allowing for expansion and contraction results in roof leaks and makes roof systems more vulnerable to storm and wind damage.

Material behavior

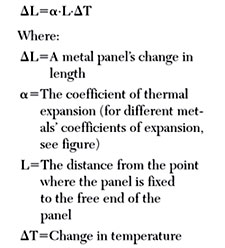

When a metal panel is heated or cooled, its length changes by an amount proportional to the original length and temperature change. The amount of movement can be calculated by the fundamental equation:

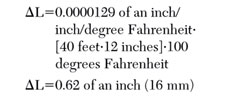

As an example, how much will a 40-foot (12.2-m) aluminum panel fixed at the ridge expand with a 100-degree Fahrenheit (56-degree Celsius) change in temperature?

Design

Movement along a panel's length from ridge to eave is an important concern with most standing-seam metal panel roof systems. Horizontal movement of a panel is of less concern because the seam-to-seam width typically is relatively small.

If panels are short, movement along their lengths generally is not a great concern. Clips used in short panels usually are one piece and designed to accommodate panel movement by rolling and flexing. Conversely, long panels can move several inches. For long panels, two- or three-piece clips are used because they allow the panels to slide back and forth or accommodate panel movement by flexing, rolling or sliding.

Typical metal roof systems fix panel expansion and contraction in a predetermined direction. Panel movement must be allowed to occur in one of three ways: upslope, downslope or both directions simultaneously. This can be achieved by providing a fixed point of attachment either at the hip and ridge, at the eave and valleys, or in the middle of roof panels. In cases where panel movement is fixed in the middle of a panel with both ends free to move, maximum movement at each end would be half of what it would be if the panel were fixed at one end and all the movement were directed to the opposite end.

Expansion coefficients of metals commonly used in roof systems

Where to fix the panel is a design consideration that must be well-planned. The location should be a horizontal point shared by all panels so panel movement is consistent from one panel to another.

For more information, roofing professionals are encouraged to refer to the Architectural Sheet Metal and Metal Roofing section of The NRCA Roofing and Waterproofing Manual, Fifth Edition; Manual for Inspection and Maintenance of Steep-slope Architectural Metal Panel Roof Systems: A Guide for Building Owners; or Manual for Inspection and Maintenance of Low-slope Structural Metal Panel Roof Assemblies: A Guide for Building Owners. Roof system designers can contact NRCA at (847) 299-9070 or click here to access NRCA's Web site, www.nrca.net.

Joan P. Crowe is an NRCA manager of technical services.

COMMENTS

Be the first to comment. Please log in to leave a comment.