Roofing contractors always are looking for better, quicker and easier methods to install insulation in roof systems. Sometimes, there are job-specific constraints, such as the inability to use mechanical fasteners (screws and plates) or materials that create unpleasant odors. When something like this occurs, the use of a polyurethane roof insulation board adhesive may be the solution.

Types

There are two types of polyurethane roof insulation board adhesives used to secure elements of roof systems: one-component and two-component. One-component products generally are known as "moisture-cured" adhesives, and two-component products generally are known as "chemically cured" adhesives. Both inherently do not penetrate deck systems and are considered to be odorless or low-odor materials.

To properly activate and set, one-component adhesives rely on moisture in the air. One-component adhesives generally are sprayed from a portable, pressurized container using a wand that produces a polyurethane foam bead or poured from 1-, 2 1/2- or 3-gallon canisters in a semiliquid state. A single canister can be used to place a single bead of adhesive, or a wheeled piece of equipment capable of carrying four or more canisters of adhesive can be used to place multiple beads of adhesive at one time.

Two-component adhesives rely on a chemical reaction between a resin-based component and diisocyanate-based component to react and set properly. Two-component adhesives are dispensed from a 14- to 18-inch-long static dispenser resembling a caulk gun with two tubes. The mixing of the two components occurs within the dispenser's tip. In addition, static dispensers may be battery-driven to help provide a more controlled, consistent adhesive bead. Static dispensers also can be bundled in specialty equipment to allow simultaneous placement of multiple beads of adhesive.

Alternatively, there are large mixing carts that hold 5-gallon containers. The carts use separate containers for each component, a dispensing tube and mixing tip. The components are mixed within the tip, which generally is a removable piece to facilitate easy cleanup. The large mixing carts are more efficient for dispensing large quantities of adhesive.

Adhered components

Polyurethane roof insulation board adhesives are used to adhere insulation to a roof deck, insulation to a base sheet, insulation to insulation and gypsum board to insulation. Re-cover boards can be adhered to certain existing roof membranes depending on a membrane's surface characteristics. Common deck types include concrete, steel and wood. Adhesives also may be used with cementitous wood fiber and gypsum decks. Common insulation types include polyisocyanurate, perlite, polystyrene and wood fiber.

The surface characteristics of the components receiving a polyurethane roof insulation board adhesive are critical to the adhesive tenacity and, ultimately, a roof system's uplift resistance. Surfaces need to be adequately porous to allow the polyurethane material to "bite" and form a strong adhesive bond.

The use of polyurethane adhesives should be evaluated with the adhesive manufacturer for each re-cover project because the parameters of re-cover projects can vary significantly. There are many types of re-cover boards available (gypsum, wood fiber, perlite), and each will provide a different uplift resistance. The use of adhesives to secure re-cover boards will be limited to a few types of existing roof systems.

Installation

Application rates for polyurethane roof insulation board adhesive generally are in the range of one bead every 12 inches on center. However, there is a lack of consistency in manufacturers' literature with regard to exact application rates. One manufacturer's literature states, "1 foot of adhesive for every square foot of insulation board," requiring that the outermost beads be 3 inches from the board edges. That means the beads actually are 14 inches on center on a 4-foot-wide board. Other manufacturers' literature state beads are placed "12 inches on center." These application rates are similar but not identical. NRCA suggests users verify the exact installation application rates with manufacturers before beginning projects.

Application rates for polyurethane adhesives sometimes can be increased to increase the uplift resistance of roof systems. Adhesive beads at 6 inches and 9 inches on center also commonly are recommended application rates at corners and perimeters.

Installation temperatures for one-component adhesives are above freezing (33 F and higher) and rising. Ambient and surface temperatures need to be above freezing because liquid moisture is needed to initiate the reaction.

Two-component adhesives can be installed at temperatures of 40 F to 45 F and higher depending on the specific manufacturer. Because the two-component materials react exothermically (meaning heat is released during the chemical reaction), if substrates are too cold, there is a possibility the reaction will not occur properly, resulting in unreacted or off-ratio polyurethane adhesive and unadhered materials. However, there are formulations for two-component adhesives that allow installation at temperatures as low as 0 F.

On the high-temperature end, manufacturers recommend the maximum surface temperature be 120 F. It is well-known roof surface temperatures easily can exceed 120 F, so this requirement is unrealistic on sunny days when working with dark or black substrate materials, such as dark-faced polyisocyanurate insulation boards or base sheets. Specifiers and manufacturers should be aware this requirement likely will not be met during the course of typical daytime summer conditions, and the workday schedule may need to be adjusted to compensate for substrate temperature conditions. However, it is likely many projects have been installed successfully above the recommended temperature limit; therefore, this is an installation parameter that should be re-evaluated by manufacturers to accommodate real-world parameters.

Insulation boards are placed immediately after pourable one-component adhesives are applied. For sprayed one-component adhesives, placement of insulation boards should occur within a few minutes. Although both types of one-component adhesives require moisture to activate and set, the time parameters for insulation placement vary significantly. Also, insulation boards need to be stepped in or weighted for a certain time to allow the adhesive to adequately secure the components.

The reaction time for one-component adhesives will vary depending on humidity levels. The higher the humidity, the faster the reaction time. The lower the humidity, the slower the reaction time. For roofing contractors, this translates to the amount of time required to wait before setting insulation boards into newly placed beads of adhesive. Higher humidity requires less waiting time; lower humidity requires longer waiting time.

When there is too little humidity at the point of application, misting a one-component polyurethane roof insulation board adhesive with water or an accelerator can provide adequate moisture to speed up reaction time. Millenium Adhesive Products Inc., Bradenton, Fla., allows this practice when a quicker reaction is desired. However, NRCA does not recommend this technique because it is unlikely it can be controlled and monitored effectively.

For one-component spray adhesives, if the relative humidity is too low at the point of contact and adequate time is not allowed between adhesive installation and board placement, there is potential for uncured adhesive to be absorbed into the insulation to be secured. This creates the possibility for a nonreacted adhesive and no adhesion between the two roof assembly components. This is a concern on dark or black surfaces (such as dark-faced polyisocyanurate insulation board) when installation occurs on a warm, sunny day. Even though there is adequate humidity above the surface of the roof (about 3 feet to 6 feet up), the elevated temperature of the dark or black surface significantly reduces the relative humidity in the air at the point of adhesive application. This slows the adhesive reaction time so it is necessary to wait before setting an insulation board in the adhesive. Determining how long to wait to set boards is critical with one-component polyurethane adhesives.

Theoretically, humidity levels should not affect two-component adhesives. However, similar to other two-component polyurethane roofing materials, when the surface temperature is too close to the dew point (within 5 degrees Fahrenheit), there is a possibility condensation may occur and interfere with the reaction of the two components, creating an off-ratio polyurethane. In addition, liquid moisture can affect a two-component polyurethane adhesive's chemical reaction, resulting in materials that do not have desirable adhesive properties.

For two-component adhesives, the mix ratio is critical. Mix ratios are intended to be 1-to-1. If components are off-ratio by as little as 5 percent or 10 percent, the mixture will not react properly and the adhesive properties of the material will be lost. Keeping ratios consistently 1-to-1 requires materials to be at the proper temperatures and, depending on the dispensing system, proper pressures within the equipment to keep the materials flowing consistently.

Roof decks

Roof decks, in general, should be clean and visibly dry so adhesives will adhere to the surfaces. Decks need to have even surfaces so insulation boards will lie flat against decks without gaps or voids. Uplift resistance generally will increase with the rigidity of the roof deck and corresponding less deflection. For example, a concrete deck likely will provide greater uplift resistance than a wood deck, all other things being equal. Also, a 20-gauge metal roof deck will provide greater uplift resistance than a 22-gauge metal roof deck. This is because of the potential for movement of the roof deck during dynamic loading, which may cause a reduction of adhesion over time (fatigue of the adhesive because of repetitive cycling).

Concrete roof decks should be cured properly before application of polyurethane roof insulation board adhesive. Residual moisture in concrete may benefit a one-component adhesive; however, installation of organic-faced insulation may not be appropriate if there is too much residual moisture in the concrete. Acceptable amounts of residual moisture are difficult to quantify.

Manufacturers that offer polyurethane roof insulation board adhesive

Steel decks should be a minimum 22 gauge. Metal decks generally are either galvanized or painted. Painted steel roof decks should be primed. Painted and primed steel decks generally will provide better adhesion than galvanized steel decks. However, because of a lesser amount of porosity of a steel deck's surface (relative to concrete and wood), polyurethane adhesives do not adhere as well to steel decks as they do to concrete and wood decks.

NRCA recommends that if polyurethane adhesive is used to secure roof insulation over a metal deck, a rigid board first is mechanically fastened to the metal deck. This contradicts one of the reasons to use adhesives—to eliminate fasteners through a metal deck. However, there are other reasons to use adhesives, such as to eliminate thermal bridging.

Insulation and rigid boards

Many types of insulation can be adhered using polyurethane adhesives. The tenacity of the adhesion to different types of insulation will vary because of surface characteristics and facer differences. Insulation boards must be flat, clean, dry and generally dust-free.

Insulation boards usually are limited to 4 feet by 4 feet as an additional precaution to decrease the tendency for bowing and cupping, which create voids or gaps below the boards. Four- by 8-foot boards may be able to be walked in and held in place, but large boards are susceptible to internal stresses and potentially can bow or cup. These additional stresses placed on the adhesive may be detrimental to a roof system's long-term uplift resistance.

Rigid boards, such as fiberglass-faced gypsum boards, generally lie extremely flat and, therefore, 4- by 8-foot sized boards can be used. Because these types of gypsum boards come with different facers, you should verify with the manufacturer that the specific facer type has been tested appropriately for adhesion. It is important for the polyurethane adhesive to adhere properly to the gypsum board's facer given the varying ambient conditions during a roofing project and also provide the desired uplift resistance.

Manufacturers

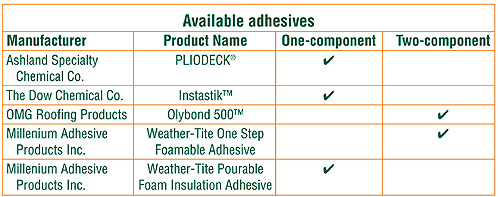

NRCA currently is aware of four manufacturers of polyurethane roof insulation board adhesive, which are listed in the figure. There likely are other products available that are private-labeled, but the figure lists material manufacturers and their product names.

A manufacturer of one-component polyurethane adhesives recently introduced a faster-reacting one-component adhesive product that should be released by the end of 2006. This should assist applicators with some of the application-time concerns (such as waiting for moisture pickup to begin the reaction) of one-component adhesives.

Information and testing

FM Approvals does not allow approval of roof systems attached to metal roof decks with adhesives, so there are no FM approvals for roof systems adhered to metal decks with polyurethane roof insulation board adhesives. Underwriters Laboratories Inc. provides listings for roof systems attached to metal roof decks with adhesives.

Understanding

Although polyurethane roof insulation board adhesives have been used in the industry for nearly 20 years, these adhesives now are becoming a larger part of the roofing industry. Roofing professionals should understand the differences among the types of adhesives, be aware of the limitations of their use and understand the specific installation instructions for each type of adhesive used. Also, applicators must be aware that polyurethane adhesives are application-sensitive relative to the ambient temperature and relative humidity at the point of application. Appropriately specifying and installing these products is critical to a roof system's success.

James R. Kirby is an NRCA senior director of technical services.

COMMENTS

Be the first to comment. Please log in to leave a comment.