Step flashing typically is found in most steep-slope roof systems where a roof area intersects a side wall. However, for tile roof systems, channel flashing may be used.

Channel flashing, also referred to as pan flashing, frequently is installed with pan tiles and cover tiles (barrel or mission tiles) or S-tiles. Channel flashing differs from step flashing because it extends under the tile along the entire length of the roof/wall intersection instead of being interwoven between tile courses. Other common locations for channel flashings are the sides of chimneys, dormers and curbed penetrations.

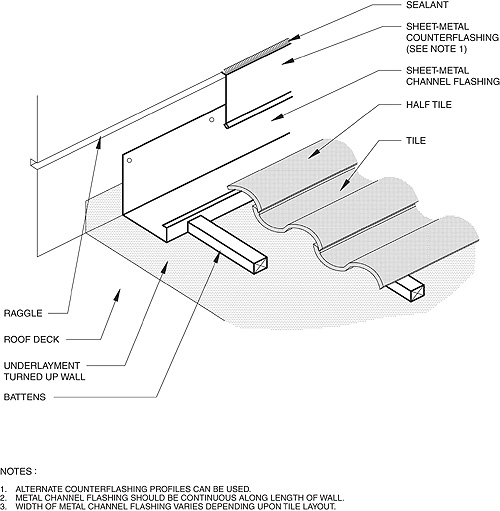

Channel flashing requires some form of counterflashing to cover and protect the top edge from water infiltration as shown in the detail. In some cases, wall covering or cladding material may be the counterflashing. Where wall cladding meets wall flashing metal, NRCA recommends cladding material and underlayment extend past and cover the flashing metal's top edge by a minimum of 2 inches (51 mm). The cladding material should be at least 1 inch (25 mm) above the roof surface.

If wall covering or cladding material cannot be used as counterflashing, a sheet-metal counterflashing should be used. Counterflashing can be surface-mounted or inset into a masonry joint or raggle.

Detail Tile-2 from The NRCA Roofing and Waterproofing Manual, Fifth Edition

Special attention should be given to the bottom of the channel flashing. NRCA recommends a sheet-metal diverter, which directs water away from a wall and off a roof. The joints in the diverter should be soldered or sealed to make the diverter weathertight.

The type and minimum thickness of the metal used for channel or step flashings should be commensurate with the anticipated service life of the tile roof system. NRCA suggests channel flashings be constructed from the following metal types and thicknesses:

In some regions, particularly those with mild climates, other types of metal and/or metals of lesser thicknesses than previously mentioned may be used successfully. NRCA considers these applications to be area practices.

Joan P. Crowe is an NRCA manager of technical services.

COMMENTS

Be the first to comment. Please log in to leave a comment.