A roof clear of mechanical equipment has fewer items to detail, flash and maintain and reduces roof traffic, making work on a roof easier to handle.

For this reason, NRCA recommends mechanical equipment be installed somewhere other than on a roof, such as in penthouses or at ground level. Unfortunately, it is common to find mechanical equipment located on a commercial or institutional low-slope roof system.

If mechanical equipment is to be placed on a roof, NRCA suggests the equipment be installed on curbs instead of support stands to eliminate the need for roof application or service work under mechanical units when reroofing or maintenance becomes necessary.

However, if a mechanical unit is mounted on support stands, it should be raised a sufficient height above the roof surface to allow space for proper roof system installation and making repairs beneath the unit.

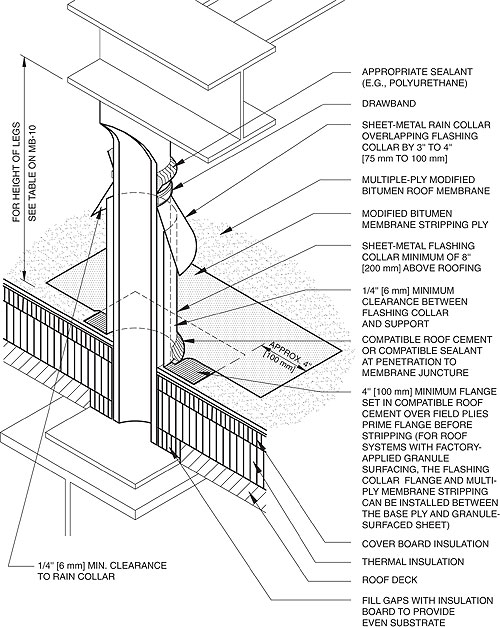

Detail MB-11 from The NRCA Roofing and Waterproofing Manual, Fifth Edition

NRCA also recommends units mounted on steel frames be supported by round steel pipes or square tubes instead of steel angles or "W" shapes to facilitate effective flashing installations.

For modified bitumen roof systems, pipe penetrations should be flashed into the membrane with a flashing collar fabricated from soft metal, such as sheet lead or copper. The detail shows there should be a minimum of 1/4-of-an-inch (6-mm) clearance between the pipe penetration and flashing collar.

The flange width of the flashing collar should be a minimum of 4 inches (102 mm). The flanges should be primed, set in a bed of asphalt roof cement and stripped into the roof system with a modified bitumen stripping ply. For roof systems with factory-applied granule surfacing, the flange and multi-ply membrane stripping can be installed between the base ply and granule-surfaced sheet.

The detail also shows a sheet-metal rain collar secured in place with a drawband. The rain collar should be formed to accept a bead of sealant above the drawband. An appropriate sealant, such as polyurethane, should be used and installed in such a manner to facilitate runoff.

The flashing collar should be a minimum of 8 inches (203 mm) above the roofing, and the rain collar should overlap the flashing collar by 3 inches to 4 inches (76 mm to 102 mm).

Joan P. Crowe is an NRCA manager of technical services.

COMMENTS

Be the first to comment. Please log in to leave a comment.