Rooftop-mounted photovoltaic (PV) system installations have grown in popularity and acceptance in the U.S. However, with many installations, there appears to be a lack of adequate consideration for the roof systems over which PV system installations are applied.

Regardless of the electricity production and associated cost savings a rooftop-mounted PV system can provide, if a rooftop PV system installation results in leakage or reduced roof system performance or service life, the building owner will be unhappy with the outcome.

Following is an overview of roof system considerations that need to be evaluated and implemented with rooftop-mounted PV system installations.

Why rooftop PV?

Roofing professionals often ask: "Why put PV panels on a building's roof? Can't they just go on the ground?"

Although ground-mounted PV systems have been successfully in place for years, much of the growth in the U.S. PV industry has been with rooftop-mounted applications.

Rooftop-mounted PV systems offer some advantages over ground-mounted PV systems. First, rooftop-mounted PV systems take advantage of the otherwise underutilized rooftop space instead of taking up valuable ground-level real estate.

Rooftops also are relatively secure from passersby whereas ground-mounted systems typically need to be fenced off or otherwise secured to limit access. For low-slope roofs, rooftop-mounted PV systems also may not be visible to passersby.

Also, because rooftop-mounted PV systems are located on buildings, they are close to electrical transmission lines already serving the buildings. Ground-mounted PV systems may be far from transmission lines necessitating relatively costly transmission line construction and interconnections costs.

Rooftop-mounted PV systems have some specific disadvantages compared with ground-mounted PV systems. Rooftop-mounted PV systems need to interact with the building, including the building's roof assembly on which it is installed, and should not cause diminished roof system performance or leakage. Maintaining building component performance and preventing leakage are not concerns with free-standing, ground-mounted PV systems.

Also, rooftop-mounted PV systems need to comply with building code requirements, including specific fire-resistance, wind-resistance and performance requirements, in addition to electrical code requirements. The fire code also has building-specific requirements applicable to rooftop-mounted PV systems, which do not apply to ground-mounted PV systems.

Equivalent service life

One of the first—and maybe most important—considerations for a rooftop-mounted PV system is for the roof system to have an expected useful service life equal to or greater than that of the PV system being installed. This is intended to minimize the need to partially dismantle or completely remove the rooftop-mounted PV system to provide for any necessary roof system repairs or replacement. Not only is unanticipated PV system removal and replacement costly, it also interrupts the anticipated electrical generation and associated cost savings, as well as the expected payback period of the original installation's costs the rooftop-mounted PV system is intended to provide.

PV systems often are reported to be manufactured to have service lives of about 25 years or more. Specific service life information typically is available from individual PV system manufacturers.

Roof systems, on the other hand, do not have specific service life designations. Experience has shown roof systems' useful service lives vary significantly depending on the roof system design, roofing materials used, installation workmanship and owners' maintenance. Although some roof system types such as slate, clay tile and copper architectural metal panel have been known to have service lives of 50 years or more, other roof system types are known to have significantly shorter service lives.

NRCA does not recommend a roof system manufacturer's long-term warranty be used to predict a roof system's useful service life. There is little to no actual correlation between the two.

A roofing industry study conducted in 2003 by The Roofing Industry Alliance for Progress shows the average life expectancy for a low-slope roof system on a commercial building in the U.S. is about 17.4 years.

Based on this, most roof systems underneath rooftop-mounted PV systems clearly will need to have above-average levels of design, materials application and maintenance to achieve service lives equivalent to or greater than the reported service lives of PV systems.

The most efficient means of maximizing the useful service life of a roof system underneath rooftop-mounted PV systems is for a new roof system to be installed at the time of the rooftop-mounted PV system installation. This allows for full use of the roof system's useful service life to achieve the important equivalent service life consideration.

NRCA suggests building owners and homeowners exercise caution if they are considering having a rooftop-mounted PV system installed on an existing, deteriorated roof system. In this situation, a portion of the roof system's expected useful life already has been expended and the likelihood of achieving the equivalent service life consideration is relatively low.

If a rooftop-mounted PV system is installed on an aged, deteriorated roof system, the building owner should be aware of the likely necessity to perform large-scale roof system repairs or replacement before the end of the PV system's service life. Such roof system repair or replacement undoubtedly will necessitate partial or possibly full removal of the rooftop-mounted PV system to allow for the necessary roofing work.

PV-ready roof systems

In addition to the equivalent service life consideration, some additional enhancements to roof system design should be considered to make a roof system "PV ready."

For low-slope roof systems, NRCA recommends the following enhancements:

For steep-slope roof systems, NRCA recommends:

SPRI Industry Information Bulletin No. 1-13, "A Summary of SPRI Membrane Manufacturer Photovoltaic (PV) Ready Roof Systems and Services," provides the results and recommendations from a SPRI member survey regarding rooftop PV system installations. The survey resulted in several suggestions and recommendations, including:

The bulletin concludes rooftop-mounted PV system installation needs to be closely coordinated with roof membrane manufacturers because manufacturers may have additional specific recommendations.

The Asphalt Roofing Manufacturers Association (ARMA) has issued two technical bulletins applicable to rooftop-mounted PV system installations.

ARMA's "Photovoltaic Systems and Low-slope Commercial Roofs" addresses safety and product handling; design, installation and maintenance; and rooftop PV system standards and testing approvals applicable to rooftop-mounted PV systems on built-up and polymer-modified bitumen membrane roof systems.

ARMA's "Photovoltaic Systems and Asphalt Shingle Roofs" discusses safety and product handling and design, installation and maintenance applicable to rooftop-mounted PV systems installed on asphalt shingle roof systems. The document references NRCA's Guidelines for Roof-mounted Photovoltaic System Installations for additional information.

Roof system penetrations

Rooftop-mounted PV systems typically result in more roof system penetrations and flashing conditions than conventional roof systems. Properly addressing these rooftop penetrations is an important roof system performance and watertightness consideration.

Most roof system penetration and flashing conditions encountered with rooftop-mounted PV systems are fundamentally similar to those used with conventional roof systems. For example, flashings for electrical conduit penetrations and supports, equipment supports and rail curbs are similar whether they apply to rooftop-mounted PV systems or rooftop-mounted HVAC equipment.

NRCA Guidelines for Rooftop-mounted Photovoltaic Systems and The NRCA Roofing Manual should be consulted for specific roof flashing guidelines for these detail conditions. For some roof system types, roof membrane system manufacturers have prefabricated flashings for specific flashing conditions.

There are several PV panel and rail support systems currently on the market that are less than desirable from a long-term roof system watertightness standpoint. For example, angle- or L-bracket PV panel supports intended to be attached to roof decks through steep-slope roofing products using sealant-applied or gasketed, exposed fasteners (lag screws) are problematic and likely will not provide for long-term watertightness. Experience has shown exposed fasteners in a roof system's drainage plane are prone to leakage over time and require frequent maintenance.

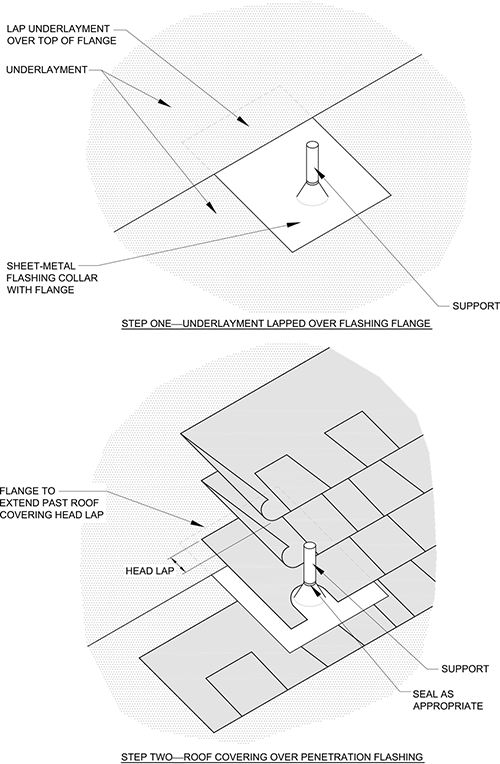

Proper flashing of a rack support; an asphalt shingle roof system is shown. |

The figure shows a proper flanged support flashing configuration that is preferred for this condition. Several PV support manufacturers make one-piece support and flanged flashings that can be used.

Ballasted PV rack systems

Nonpenetrating membrane, ballasted PV rack systems sometimes are used as support systems for rooftop-mounted PV systems. Proponents for ballasted PV rack systems indicate they eliminate the need for many roof system penetration flashings required with conventional direct-to-building structure- or deck-supported PV rack systems.

Some ballasted PV rack systems also are marketed to eliminate the need for roofing contractor involvement with rooftop-mounted PV system installations.

NRCA has concerns with ballasted PV rack systems. Such systems transfer the ballast weight required to resist wind-uplift loads directly to the roof system's surface. In many instances, the required ballast loads, which are concentrated where the ballasted rack systems contact the roof surface, exceed the compressive strength of the roof system's membrane and insulation. In some instances, these ballast loads also exceed the capacities of some roof decks and joists.

An additional concern is ballasted PV rack systems tend to move laterally on the roof system's surface in high wind-loading and seismic conditions. Experience has shown roof surface abrasion as a result of rack system sliding is detrimental to satisfactory long-term roof system performance.

NRCA is of the opinion ballasted rack systems do not satisfy the equivalent service life criteria necessary for successful roof system performance throughout the useful life of rooftop-mounted PV systems. Ballasted rack systems also are not consistent with NRCA's best practices approach, which for years has successfully served as the basis for The NRCA Roofing Manual.

Closing thoughts

NRCA recognizes rooftops are an attractive and viable platform for installing PV systems. But it is important to remember a roof system's primary function is to protect a building or home and its contents and occupants from the weather, including water leakage. Proper consideration of the specific roof system to which a PV system is applied is essential in all rooftop-mounted PV system installations. This consideration needs to take place not only during the time of PV system installation on the rooftop but also during the planning and design phases.

In addition, building owners and homeowners will need to commit to enhanced levels of maintenance and repairs to roof systems as a result of the additional usage and rooftop traffic resulting from a rooftop-mounted PV system.

Additional information regarding installing rooftop-mounted PV systems is provided in NRCA Guidelines for Rooftop-mounted Photovoltaic Systems. The document references requirements contained in NFPA 70: National Electrical Code, 2014 Edition; International Building Code: 2015 Edition; International Fire Code, 2015 Edition and the standards applicable to these codes.

NRCA is updating its PV guidelines document to include the 2017 and 2018 codes and reference standards. The updated document should be available in early 2018.

Roofing industry and PV professionals interested in providing input to NRCA's PV guidelines update are encouraged to call NRCA's Technical Services Section at (800) 323-9545.

Mark S. Graham is NRCA's vice president of technical services.

PV installer or roofing contractor?

Rooftop-mounted photovoltaic (PV) system installations always should involve a professional roofing contractor and licensed electrician. The involvement of a licensed electrician is necessary to oversee the proper installation of a PV system's electrical components; most jurisdictions have requirements for licensed electricians to perform that function. Also, a number of state and local governments have enacted special licensing requirements for PV system installers.

NRCA also recommends rooftop-mounted PV system installation only should be undertaken with the involvement of a professional roofing contractor employing skilled roofing workers for a number of reasons, including:

For these reasons, NRCA considers a building owner to be best served when a professional roofing contractor (preferably one with whom the building owner has an ongoing relationship), the roof system manufacturer and a licensed electrician be involved in a rooftop-mounted PV system installation.

COMMENTS

Be the first to comment. Please log in to leave a comment.