Photo courtesy of Advanced Roofing Inc., Fort Lauderdale, Fla.

Photo courtesy of Advanced Roofing Inc., Fort Lauderdale, Fla. Photo courtesy of Advanced Roofing Inc., Fort Lauderdale, Fla.

Photo courtesy of Advanced Roofing Inc., Fort Lauderdale, Fla. Photo courtesy of Advanced Roofing Inc., Fort Lauderdale, Fla.

Photo courtesy of Advanced Roofing Inc., Fort Lauderdale, Fla. Photo courtesy of Advanced Roofing Inc., Fort Lauderdale, Fla.

Photo courtesy of Advanced Roofing Inc., Fort Lauderdale, Fla. Photo courtesy of Advanced Roofing Inc., Fort Lauderdale, Fla.

Photo courtesy of Advanced Roofing Inc., Fort Lauderdale, Fla.From daily weather forecasts, severe storm warnings and climate monitoring to fisheries management, coastal restoration and marine commerce support, the National Oceanic and Atmospheric Administration's (NOAA's) products and services support economic vitality and affect more than one-third of the U.S.' gross domestic product, according to NOAA.

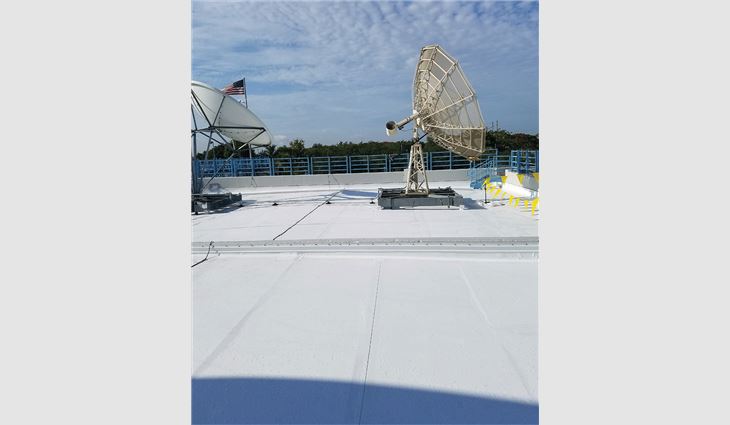

Located on Florida International University's campus in Miami, NOAA's National Hurricane Center is a one-of-a-kind operation featuring advanced hurricane tracking technology relied upon by the U.S., Latin America and the Caribbean. Since moving to its current location more than 20 years ago, poorly serviced HVAC equipment and weather satellite dishes compromised the hurricane center's roof system integrity over time.

Maintaining a fully operational facility with capabilities to monitor severe weather throughout the U.S. and provide ample warnings and weather forecasts to those living in affected areas is critical to the safety of millions of people. When the National Hurricane Center's roof system began leaking in 2016, NOAA called Advanced Roofing Inc., Fort Lauderdale, Fla., to perform repairs.

Building a new roof

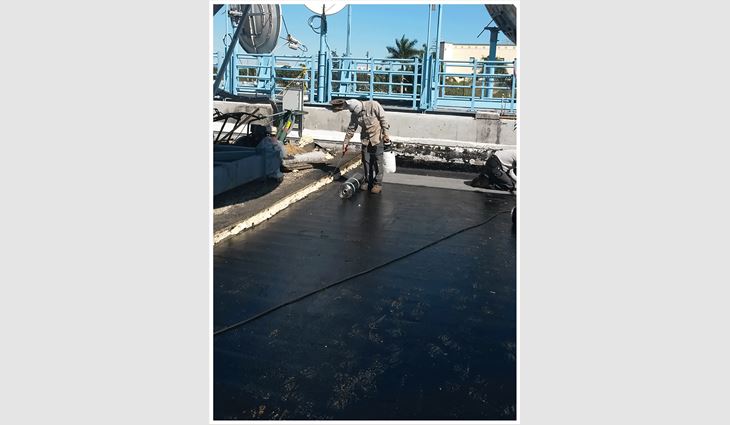

As the existing roof system was failing, water leaked through the rooftop's large satellite dishes and into a mechanical room underneath. Wasting no time, in February 2016, Advanced Roofing's crew began removing the existing roof system composed of 1/4-inch built-up roofing with gravel, 1 1/2-inch-thick high-density wood fiberboard and 3 1/2-inch-thick adhered polyisocyanurate insulation down to the structural concrete roof deck.

Working in sections, each day workers only removed what they could re-cover the same day with SOPRALENE® Flam 180, an SBS polymer-modified bitumen base ply that was heat-welded directly to the concrete deck to act as a "temporary roof" while the permanent roof system was installed.

"As the National Hurricane Center's command center remains operational even through a Category 5 hurricane, it was important to provide a temporary roof to protect the facility and its occupants while they provide storm updates to protect residents in South Florida and throughout the nation," says Matt Cooper, project manager for Advanced Roofing.

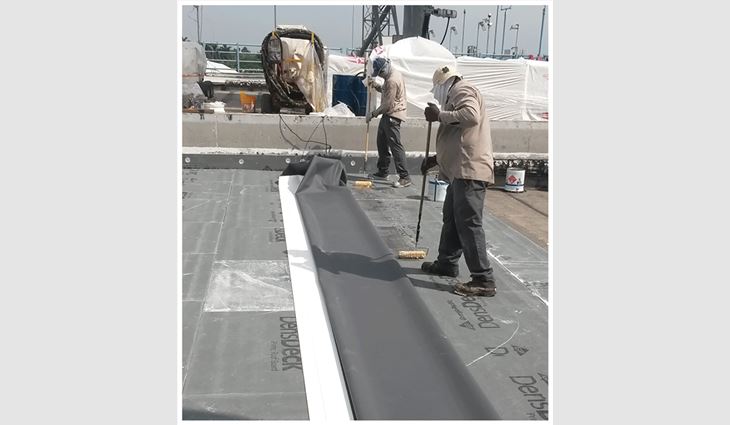

After the temporary roof membrane was adhered, the Advanced Roofing crew began installing the permanent roof system in sections. Using two-part Sika® Sarnacol® AD Board Adhesive, workers adhered two layers of 2.6-inch-thick Sarnatherm® 25-psi (pounds per square inch) polyisocyanurate insulation weighted for proper adhesion and one layer of 1/2-inch-thick Securock® cover board followed by 60-mil-thick PVC single-ply Sarnafil G410 EnergySmart Roof® Membrane adhered in Sarnacol 2170 adhesive.

"The combination of the temporary and permanent roof systems offers advantages that exceed the limitations of each roof system type on its own," Cooper says. "Combined, it is one of the best roofs NOAA could have installed on its building, and it's guaranteed to remain watertight for 25 years or more with minimal maintenance."

In addition, the National Hurricane Center's existing adjacent rooftop structural walls are made from exposed poured concrete with a porous surface. As an alternative to fully encapsulating these walls with a roof membrane, Advanced Roofing workers used SikaQuick® Smooth Finish mortar to skim-coat all surfaces to be waterproofed. Workers then coated the walls with one layer of Sikagard® 552W Primer and two subsequent layers of Sikagard 550W Elastocolor elastomeric coating. The existing edge metal was Kynar®-coated and painted blue to match the facility and fastened per Miami-Dade County requirements.

Facing challenges

Because the National Hurricane Center operates 24 hours per day, seven days per week, 365 days per year, the facility could not be offline at any point. This posed a unique challenge as the Advanced Roofing team had to be sensitive to the needs of building tenants and coordinate every move on the building's roof with NOAA management. For example, to ensure building occupants were not disturbed, Advanced Roofing rescheduled tear-off work originally scheduled to occur during an NOAA conference hosted at the facility.

Perimeter warning lines and a safety monitor were used during the project's duration, and Advanced Roofing's safety department performed periodic safety inspections. The facility contains important mechanical, satellite communication and weather-monitoring equipment, so extra care was taken to avoid damaging the equipment.

Additionally, the general contractor hired a HVAC contractor to replace the rooftop units. During replacement, it was determined the HVAC coils needed to be replaced, pushing back completion of the HVAC work and the roof system replacement schedule. Because of this, roofing materials needed to be shifted to be used on other roof areas.

After the HVAC work was completed, it was discovered the curbs installed by the HVAC contractor were leaking and retaining water under the HVAC units. This also stalled the project and forced Advanced Roofing to accommodate a double counterflashing to make the curbs watertight.

As Advanced Roofing's work progressed, NOAA requested an accelerated timeline to complete the project in time for hurricane season. To accomplish this, Advanced Roofing brought in an additional crew to focus solely on the waterproofing tasks, and two Advanced Roofing crews worked simultaneously for a portion of the project.

Blue skies ahead

At several points during the project, roofing work on the National Hurricane Center was halted to prevent disrupting occupants, rescheduled to accommodate HVAC repairs and then accelerated to complete work before hurricane season began. Despite many challenges, Advanced Roofing completed its work in May 2016, in time for hurricane season and without any disruptions to rooftop satellite equipment.

"The most rewarding part of the job was completing the project in time for the hurricane season with no interruptions to the operations at one of the nation's most vital weather facilities," says Matt Ladd, vice president of operations for Advanced Roofing. "Now, when a hurricane season arrives in full force, the Advanced Roofing team knows the National Hurricane Center's roof system will protect building occupants as they ride the storm out at command center during a hurricane."

Indeed, during 2017, Hurricane Irma blew through southern Florida and caused more than $21 billion in damage and has been blamed for at least 84 deaths, according to The Associated Press. However, NOAA's National Hurricane Center's new roof system fared the storm with no damage.

"We are proud of our crew's hard work and excellent craftsmanship," says Faustino Perez, construction manager for Advanced Roofing. "When we completed the project, the final result was a stunning roof. I am happy to report the roof system is in excellent condition and withstood the 2016 and 2017 hurricane seasons with no issues."

For exceptional work on the National Hurricane Center, Advanced Roofing received a 2017 NRCA Gold Circle Awards honorable mention in the Outstanding Workmanship: Low-slope category.

Project name: National Hurricane Center

Project location: Miami

Project duration: February-May 2016

Roof system type: PVC

Roofing contractor: Advanced Roofing Inc., Fort Lauderdale, Fla.

Roofing manufacturers: Sika® Sarnafil Inc., Canton, Mass; SOPREMA® Inc., Wadsworth, Ohio; USG Corp.,

Chicago

Gold Circle Awards category: Outstanding Workmanship: Low-slope

COMMENTS

Be the first to comment. Please log in to leave a comment.