Interest in energy-efficient roof systems has never been higher. Since 2005, double-digit increases in oil, natural gas and electricity rates have spurred energy-related legislation that is quickly gaining momentum. It seems the U.S. is finally getting serious about energy efficiency.

On the low-slope side of the roofing industry, the use of cooler, more reflective roof membranes is a trend that's growing stronger each year. But reflective roof membranes are only part of the issue.

Currently, progressive roofing manufacturers are doing more than just offering reflective roof membranes that save energy in warmer climates. They also are researching and marketing new improved products and installation techniques designed to make roofing contractors' work quicker and easier. For example, labor-saving self-adhering, reflective single-ply and modified bitumen roof membranes can increase roofing contractors' profit margins and offer significant cost savings for property owners.

Reflective TPO, PVC, EPDM and modified bitumen roof membranes—and even ballasted roof systems—are a good bet for most commercial buildings in warmer climates.

Reflective and clean

Self-adhering membranes are a growing trend in the single-ply roofing industry and with good reason. These systems address energy costs, labor issues and environmental concerns.

Self-adhering roof membranes usually reduce the time, labor and materials needed to install roof membranes and accessories because the adhesive is factory-applied to the membrane. In addition, such systems' seams and accessories can be heat-welded or installed with self-adhering seams and accessories.

In the field, it takes experienced roof applicators no more than a few minutes to install a 10-foot panel to an approved and properly prepared substrate. This results in substantial labor savings, competitive bids and money saved for building owners. And because many of these membranes meet ENERGY STAR® reflectivity requirements, potential energy savings are an added bonus.

However, it is important contractors strictly follow manufacturers' recommendations regarding storage, handling and installation of these membranes. It is critical the adhesive on a self-adhering membrane achieves a strong bond to the roof substrate. In reroofing applications in particular, a roof substrate must be properly prepared before the self-adhering membrane is laid out and broomed in. In addition, these systems should not be installed in ambient temperatures below 50 F.

Single-ply retrofits

Full product lines of modified bitumen roof systems are available with reflective surfaces that meet ENERGY STAR requirements. Some of these membranes also can be self-adhered. In addition, full system warranties are available for contractors and property owners looking to retrofit existing EPDM and modified bitumen roof systems. Even specifiers above the Mason-Dixon Line are adopting the cool roofing trend.

Initially, there was concern among roof system designers about possible energy "penalties" for reflective roof membranes in cold winter climates. Theoretically, the higher surface temperatures of dark-colored roof membranes on sunny winter days tend to reduce the heating demand for buildings in certain climates.

To better understand roof membrane reflectivity, SPRI and the U.S. Department of Energy (DOE) recently sponsored a three-year research program on reflectivity. SPRI, which represents sheet membrane and component suppliers to the commercial roofing industry, devotes significant time and resources to addressing industrywide technical topics such as roof reflectivity.

Conducted at the Envelope Systems Research Apparatus at Oak Ridge National Laboratory (ORNL) in Oak Ridge, Tenn., the study examined changes of reflectivity on 18 roof membranes supplied by 10 manufacturers. Membrane color varied from white, tan and gray.

William A. Miller, an ORNL research engineer, conducted the research. Miller is co-chair of SPRI's Accelerated Testing Task Force.

The study looked at what can reduce a membrane's reflectivity and what a loss of reflectivity can mean depending on where in the U.S. a membrane is installed. For example, Miller notes a decrease in reflectivity can affect total building energy costs in areas that primarily are concerned with cooling buildings. In contrast, in areas where heating a building is more important, any loss in reflectivity will have little effect on building energy costs.

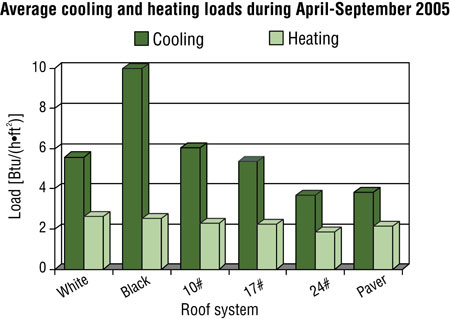

Results from a study conducted by Oak Ridge National Laboratory and the U.S. Department of Energy regarding heating and cooling loads of various roof coverings

Furthermore, the good news is ORNL's research discovered reflectivity can be completely restored by washing a membrane's surface. Roof membrane manufacturers can provide updates on the proper methods for washing installed membrane systems. (Savvy, maintenance-oriented roofing contractors might consider membrane washing as a possible business opportunity after consulting with the appropriate membrane manufacturers.)

Accelerated testing protocols would help manufacturers speed up the process of earning an ENERGY STAR rating, Miller adds. This is particularly important because current ENERGY STAR requirements require an additional three years of field testing whenever any formulation change alters a membrane's reflectance by 5 percent or more.

"In this way, with accelerated testing protocols, everybody could win," Miller says.

Where this work goes from here is up to SPRI's Accelerated Testing Task Force.

Ballasted membranes

SPRI also has released an interim report on its study "Evaluating the Energy Performance of Ballasted Roof Systems." The study's purpose is to show whether ballasted roof systems offer energy-efficiency benefits similar to those offered by cool roof systems and deserve cool status from the U.S. Environmental Protection Agency (EPA), as well as other federal and code organizations. The interim report is available for free from SPRI's Web site, www.spri.org.

The research team, led by André Desjarlais, group leader for ORNL's Building Envelope Research Program, conducted side-by-side experiments comparing different weights of ballasted roofs to a paver system and black and white membranes. The study began March 12, 2004, and continued uninterrupted for 100 weeks through April 2006; it was completed earlier this year.

After 24 months' exposure in east Tennessee, the heaviest gravel-ballasted system reduced energy flow into the test buildings. Previous ORNL studies investigated reflective membranes' performances. These combined studies have demonstrated that ballasted and reflective membrane systems reduce energy flow into buildings and, therefore, provide energy savings in cooling-dominated climates. A cooling-dominated climate is where the bulk of the energy bill to condition the space is used to provide cooling. This would include DOE's and the International Energy Conservation Code's Zones 1, 2 and the southern part of 3.

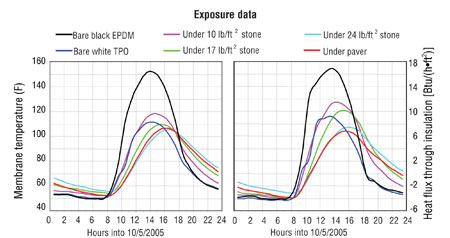

The results so far show the ballasted systems' maximum surface temperatures (90 F to 103 F) are significantly cooler than that of the black roof membrane (146 F) and approximately equal to the paver system. The white membrane stayed coolest, with its peak temperature reaching only 86 F. However, the ballasted roof systems show a delay in peak temperature from 30 minutes to two hours, keeping these roofs warmer in the early evening hours.

Membrane temperatures and roof heat fluxes 19 months into an experimental program conducted by Oak Ridge National Laboratory and the U.S. Department of Energy

By reducing peak roof temperatures and delaying heat flow into a building, the mass of a ballasted roof system provides measurable energy-saving benefits, according to the interim study. However, these roof systems currently do not meet the requirements of high solar reflectance and thermal emittance. As a result, EPA and other organizations do not recognize ballasted roof systems as being cool.

The study has also found that the heaviest ballasted roof system and paver assembly have identical area densities but substantially different solar reflectances of 0.22 and 0.55, respectively, after seven months. These observations strongly suggest the controlling parameter is mass and not solar reflectance.

The study is expected to produce three years of experimental data, and two research papers already have been written and presented on the project.

Data collection includes continuous monitoring of temperatures, heat flows and weather conditions, as well as periodic verification of the surface properties of solar reflectance and thermal emittance.

Sustainable roof systems

A single-ply roof system consists of three or four basic components: structural deck, air or vapor retarder, insulation and single-ply membrane. When installing a sustainable roof system, the manufacturing processes used to produce these components, installation procedures, roof system life expectancy, in-service performance and maintenance must be considered. Just as important is the ability to reuse, recycle or dispose of an old roof system in an environmentally acceptable manner.

As you probably are aware, there is a direct correlation between premature roof system failure and "lowest first cost" design criteria. Unfortunately, the latter is often a driving force behind the roof system selected for installation. It is here contractors' and designers' responsibility for recommending and installing sustainable roof systems is greatest. The good news is adopting sustainable roof strategies often results in longer-lasting roof systems and greater savings than the lowest first cost mentality.

Integrating energy efficiency into roof project specifications requires extra effort on the part of contractors and designers. Although often neglected in the current construction market, all roof specifications should include a detailed life-cycle cost analysis. An energy-efficient roof system that fails prematurely is an environmental disaster if you consider the energy assets required to replace the roof system and disposal costs.

SPRI members emphasize the importance of thermal insulation in lowering energy and operating costs and remain committed to promoting energy-efficient roof systems and installation techniques that are easy on the environment and safe to use. The association continues to accomplish these goals by sponsoring a variety of research programs and publishing recommended standards that can help the roofing industry become a leader in energy-efficient and sustainable roof system design. SPRI's most recent program is a study of the thermal performances of vegetative roof systems.

For more information about SPRI and its activities, visit SPRI's Web site at www.spri.org.

Mike Ennis is a technical director for SPRI.

COMMENTS

Be the first to comment. Please log in to leave a comment.