As a roofing professional, you certainly are familiar with the Occupational Safety and Health Administration's (OSHA's) workplace regulations. However, there are other regulations, especially for government work, that require your compliance and are less well-known. For example, the U.S. Army Corps of Engineers' (USACE's) "EM 385-1-1 Safety and Health Requirements Manual" contains 34 topic sections that specify safety requirements for construction projects managed by USACE. Adherence to EM 385 is backed by law through prescribed regulations or binding contract language.

As another example, a roofing contractor may be obligated by Federal Acquisition Regulation 48 CFR §52.236-13, Accident Prevention, to conform to EM 385 when performing a roof system installation for the Department of Defense (DOD), or compliance may be required under specific contract provisions for other non-DOD projects. Failure to comply with EM 385 requirements can be costly in terms of project safety, time and money.

Accident prevention plan

EM 385 safety and health requirements often track closely with OSHA's construction regulations found in 29 CFR §1926. However, there are significant differences and additional requirements in some areas. Most important is the requirement in EM 385 for a contractor to establish an Accident Prevention Plan (APP) that must be submitted to and approved by the government-designated authority (the senior person in charge of the operation or activity being conducted or his or her representative) before any work can begin.

USACE's safety and health manual's Appendix A describes the APP as a safety and health policy and program document that is contract- or job-specific and interfaces with a contractor's safety and health program. Appendix A also contains two nonmandatory Safety Inspection Checklist forms to be used by a contractor depending on the nature of the work to be performed.

According to the manual, the purpose of the checklists is to make certain a contractor provides all required information when developing an APP for a project. The abbreviated checklist form is for low-risk, limited scope projects and requires an APP to address the hazards and control methods, describe personal protective equipment to be used and detail procedures for job inspections. However, most work conducted by roofing contractors likely would require a more extensive APP and use of the second checklist. Elements to fully develop the extensive APP include:

An extensive APP also requires site-specific plans in a number of hazard areas such as fall protection, fire prevention and respiratory protection.

In addition, details regarding a contractor's risk management process are required as part of the APP. Risk management, according to USACE, is a process that identifies, assesses and prioritizes risks an entity may be exposed to and applies controls to minimize their effects. Under EM 385, the risks relate to safety and health issues. A common tool used in many industries as part of the risk management process is the job hazard analysis (JHA) or job safety analysis (JSA). USACE uses the term activity hazard analysis (AHA), and AHAs are part of EM 385's risk management requirements.

Section 01.A.12 requires a contractor to identify each major phase of work under a contract, identify all activities or tasks within each major phase, and submit an AHA for an activity to the government-designated authority for approval. Section 1 of EM 385 contains a sample AHA form, but EM 385 allows for the use of JHA or JSA forms as long as the content submitted is the same. Crews must have an AHA in their possession that describes current site conditions, personnel, equipment and control measures for the activity, and work practices must conform to the AHA.

Fire prevention

Section 9 of EM 385 addresses fire prevention and protection and contains several notable provisions. The manual prohibits placement of roofing kettles on roofs under a provision similar to that contained in NFPA 1: Fire Code. Kettle operators are required to be on the same level as kettles, within eyesight and within 25 feet of kettles. EM 385 also requires (without specification) some means of controlling spills of hot asphalt from a kettle and the placement of a fire-retardant tarp or other means of fire prevention under an operating kettle.

Roofing contractors who install torch-applied polymer-modified bitumen systems and follow the practices set out under NRCA's CERTA program generally will comply with EM 385 rules, which are less restrictive.

For example, CERTA practices require a two-hour fire watch to be maintained after the last torch is extinguished; EM 385 requires only a one-hour fire watch. In addition, CERTA requires a minimum of two 4A60BC fire extinguishers to be within 10 feet of torching operations. The fire extinguisher reference in EM 385 for "hot work" calls for what is referred to as a "fully charged fire extinguisher, minimum 10 lbs.," which is a somewhat imprecise way of referencing the type of fire extinguisher applicable to a fire hazard during torching operations.

Most regulatory or code enforcement agencies employ Underwriters Laboratories Inc.'s rating system for fire extinguishers using letters of the alphabet to denote the types of fires an extinguisher is meant to extinguish along with a numeric prefix that designates the firefighting capability of the extinguisher.

Significantly, according to EM 385, a fire-prevention plan must be included in a contractor's APP and AHAs must reflect potential fire hazards in all activities to be performed. Workers must be trained in the particulars of a contractor's fire-prevention plan.

Fall protection

Regarding fall protection, in Section 21 of EM 385, the threshold height for construction activities is the same as OSHA's rules—fall protection is required at heights of 6 feet or greater. Fall-protection system options under EM 385 include guardrails, work platforms, safety nets, personal fall-arrest (PFA) systems, engineered fall-protection systems and, on low-slope roofs with slopes of 4-in-12 or less, a more restrictive warning-line system. Provisions in EM 385 relating to fall-protection requirements during inspections are more refined than OSHA provisions.

OSHA's construction regulations do not require fall protection when workers are inspecting, investigating or assessing workplace conditions before beginning work or after all work has been completed. Under EM 385, fall protection is required during construction activities for workers inspecting, investigating or assessing a workplace. In addition, for work that takes place before or after construction work is complete, the manual states:

In each of these instances, the designated competent person for fall protection must develop and review an AHA for the inspection, investigation or assessment activity and have it reviewed and accepted by the government-designated authority. The premise is that in those instances where the activity takes place more than 6 feet from a roof edge, fall-protection requirements will be determined by the government-designated authority depending on the nature of the activity, other hazards within the activity area and control methods proposed by the competent person.

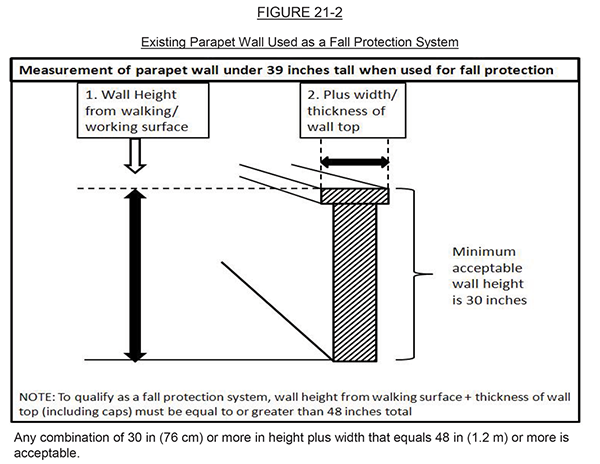

According to OSHA, an unprotected side or edge is a side or edge of a floor or roof without a guardrail or wall at least 39 inches high. EM 385 uses a similar definition but fails to specify a height. However, under EM 385's Section 21, an existing parapet wall is considered "adequate fall protection" if it is between 39 and 45 inches high or if it has a minimum height of 30 inches and sufficient width (18 inches) to reach a combined height and width sum of 48 inches (see the figure).

The principle behind this alternative measurement is the added width of a parapet that is lower than 39 inches but at least 30 inches high acts to prevent a person from falling over a wall as does a parapet that actually meets the 39-inch height.

Figure 21-2 from the U.S. Army Corps of Engineers' "EM 385-1-1 Safety and Health Requirements Manual" |

Probably the most significant difference between EM 385's fall-protection rules and OSHA rules involves the use of safety monitors. Both rules contain provisions for warning lines permitting workers to work within a flagged-off area on a low-slope roof without fall protection. However, fall protection is required when workers perform work outside the warning line.

Under OSHA rules, fall-protection options for workers operating outside warning lines include the use of a safety monitor to warn workers when they are approaching an unprotected edge or acting unsafely. EM 385 requires fall protection when workers are outside the warning lines and prohibits the use of a safety monitor as a fall-protection system; so workers outside warning lines must be protected by other fall-protection systems such as PFA systems or restraint systems.

One unique feature of a warning-line system is its distance from the roof edge when mechanical equipment is being used. EM 385 requires the line be at least 15 feet from the roof edge when workers are using mechanical equipment. In addition, if other trades are on the roof, the warning line must be set at least 15 feet from the roof edge.

One other important provision in EM 385 relates to the use of PFA systems. Rescue from an arrested fall is a critical area of equipment selection and training for contractors to consider when workers use PFA systems. The manual requires harnesses be fitted with suspension trauma relief straps or stirrups for any worker using a PFA system. Such straps or stirrups are one of the more economical options for self-rescue using a PFA system.

Learn the rules

If your company is engaged in work that involves government facilities, you likely will need to familiarize yourself with the safety and health requirements of EM 385. Knowledge of OSHA construction rules will help you distinguish among the important variations found in EM 385 and plan for additional time to get your workforce up to speed.

Harry Dietz is NRCA's director of enterprise risk management.

You can purchase a hard copy of EM 385 from publishers that sell OSHA publications, but you also can download a free PDF of EM 385 at www.usace.army.mil/Safety-and-Occupational-Health/Safety-and-Health-Requirements-Manual. EM 385 also is available as an app for iPhone, iPad and Android devices.

COMMENTS

Be the first to comment. Please log in to leave a comment.