According to NRCA's 2001-02 Low-Slope Roofing Materials Guide, there are more than 400 modified bitumen sheets available in the United States from at least 31 manufacturers/suppliers. The resulting number of potential membrane combinations is staggering—after selecting a supplier and membrane, a choice still must be made as to the most appropriate method of installation. There are more options than ever for adhering modified bitumen sheet materials, including hot asphalt, heat welding or torching, liquid cold adhesive, self-adhesive and mechanical fastening with a heat-welded overlap.

Following is some information about the benefits and drawbacks of these installation methods. Because self-adhered and mechanically fastened roof systems have relatively small market presences, they will not be addressed at length.

History

When SBS-modified bitumen products were introduced in the United States during the late 1970s, a majority of U.S. roofing contractors were installing built-up roof systems. Familiarity and practicality of using existing equipment made installing SBS-modified bitumen membranes using hot asphalt an easy choice. However, in the years since, laboratory testing and field experience have demonstrated that other interply bonding choices—solvent-based adhesives, heat welding and heat-activated self-adhesives—offer higher performance.

Recently, there has been a trend (pioneered by a small number of membrane manufacturers) to shift the application of modified bitumen roof membranes from hot asphalt toward better interply adhesives. As the modified bitumen roofing market in the United States continues to evolve and benefits of cold adhesives and heat welding are more commonly understood, these methods are being used more frequently.

Properly applied cold-adhered and heat-welded modified bitumen membrane systems achieve tenacious interply bond strengths that surpass those achieved with oxidized-asphalt applications. Furthermore, cold-adhered and heat-welded membrane systems exhibit superior physical and mechanical properties and rooftop performances in the long and short terms as compared with oxidized-asphalt-applied membranes.

All asphalts are not the same

Just as all modified bitumen sheet products are not the same, neither are all ASTM D312 Type III or Type IV asphalts. Although oxidized asphalt as an interply component in an overall membrane rarely is given a second thought, differences among ASTM D312 mopping asphalts exist that can affect long-term performances of modified bitumen membranes.

Not all ASTM D312 asphalts yield good long-term results even when used with the highest-quality SBS-modified bitumen membranes. This briefly was discussed in a Construction Technology Update, "Blistering in SBS Polymer Modified Bituminous Roofs," published by the National Research Council of Canada in 2000.

Currently, there are more than 50 asphalt plants in the United States. At each of these oxidizing plants, the asphalt flux sources can change often. This leaves slim odds that a key ingredient in a modified bitumen roof membrane assembly will remain consistent from job to job or even day to day. Monitoring mopping asphalt quality is not easy because of the factors previously mentioned. The only true way to ensure total system compatibility is to purchase mopping asphalt from the same plant that supplies the asphalt used to produce the modified bitumen sheets. But this seldom is offered as an option.

When used to adhere the same SBS-modified bitumen sheets, different mopping asphalts perform quite differently over time. If all application technique-related variables are dismissed, one critical element remains: the quality of the interply bonding agent. Bond strength plays a major role in the long-term performance of any membrane assembly.

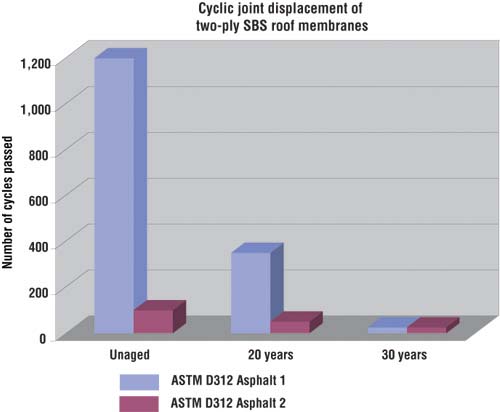

All oxidized mopping asphalts embrittle over time. The results of ASTM D5849, "Standard Test Method for Evaluating Resistance of Modified, Bituminous Roofing Membranes to Cyclic Joint Displacement," give a good indication of this phenomenon. The test procedure can differentiate between two mopping asphalt sources where other tests, including peel testing, may not.

As shown in Figure 1, when mopping asphalt ages, it loses its bond strength and ability to resist blister growth when voids exist in the interply. For this reason, even the best mopping asphalt eventually will be the weak link in hot asphalt-applied modified bitumen systems.

Figure 1: The effects of age on mopping asphalts

Although the two-ply SBS membranes represented in Figure 1 did not rupture, the asphalt disbonded in the interply. Asphalt 1 maintained adequate bond strength for more than 20 years of equivalent heat aging. Asphalt 2, on the other hand, performed poorly from the day of application. These laboratory data have been substantiated by field experience. Although years of experience and laboratory data proved Asphalt 1 to be "best of class," it was acknowledged that better interply adhesives were available that would either eliminate or mitigate the weaknesses found in all hot-asphalt applications.

Crew familiarity with hot asphalt application of roof membranes can be beneficial. The same comfort level with hot asphalt application that led contractors to use the method with SBS-modified bitumen membranes during the 1970s has helped it remain predominant. However, despite its familiarity, the many variables associated with hot asphalt application must be considered because they can affect long-term performance.

Cold adhesives

Solvent-based cold adhesives have been used successfully with modified bitumen membranes in the United States for more than 20 years. In 1996, samples of a two-ply, fiberglass-reinforced, cold-adhered SBS membrane were taken from a roof assembly installed in Ohio in 1982. When tested according to ASTM D5849, the 14-year-old two-ply membrane passed the requirement for newly installed membranes (500 cycles at 14 F [–10 C]) far exceeding the requirement for aged materials, which is only 200 cycles. This roof membrane still is performing 20 years after installation.

Cold adhesive primarily is composed of asphalt and solvent plus various mixtures of fibers, fillers and stabilizers. Despite generally superior bonding characteristics as compared with hot asphalt, the same quality issues must be considered.

For example, is a cold adhesive compatible for use with a specified modified bitumen membrane? The choice of solvent is a major factor when determining this because solvents vary by aromaticity, boiling-point range, flash point, etc. Base asphalt quality, as well as the choice and blending of related fibers, fillers and stabilizers, also are critical because the "solids" portion of an adhesive remains as the bonding agent when the solvent completely evaporates from a membrane assembly.

As with any laminated construction, a glue line affects product performance. Generally, thinner glue lines lead to better performance. Cold-adhesive applications result in much thinner glue lines than hot asphalt applications. Most modified bitumen manufacturers ask for interply mopping weights between 20 pounds per square and 30 pounds per square (0.98 kg/m² and 1.46 kg/m²) or 40 mils to 60 mils (0.04 inch to 0.06 inch [1 mm to 1.5 mm]) thick, respectively. For various reasons, such as temperature and application technique, actual interply mopping weights often exceed these specified values.

Cold-adhesive interply usage generally is specified to be between 1.5 gallons per square to 2.5 gallons per square (0.6 L/m² to 1 L/m²), which equates to 24 wet mils to 40 wet mils (0.024 inch to 0.04 inch [0.6 mm to 1 mm]). After solvent evaporation, this thickness significantly lessens depending on solvent content.

Most important, unlike hot asphalt, which merely acts as a hot-melt glue, there is a chemical bond, or type of solvent welding, that occurs when modified bitumen sheets are adhered with compatible cold adhesives. Although solvent-based adhesives tend to soften sheets during curing (or flash-off), with proper planning and job staging, difficulties associated with sheet softening can be minimized.

Depending on the type of modified bitumen sheet and solvent system, the resultant bond is similar to that achieved with torched or heat-welded membranes. Because of this interply bond's strength, the chances of long-term disbonding and blister formation are reduced greatly. Even if a small interply void exists, a blister cannot grow unless the internal pressure overcomes the interply attachment's bond strength.

Torching and heat welding

Modified bitumen roof membranes have been torch-applied in Europe for more than 30 years and North America for more than 25 years. Certain SBS-modified bitumen products specifically are designed for torching and are available with patented surface treatments intended to enhance torch welding and make installation more efficient.

Theoretically, it is impossible to improve the interply bond strengths of properly torched membranes. But, as with any application technique, mistakes can be made when torching or heat welding. Underheating will not adequately fuse sheets together, making interply blisters possible. Severe overheating certainly leads to poor aesthetic quality and potential long-term performance problems. When torched correctly, the rubberized (SBS) or plasticized (APP) asphalt compound on adjoined sheets becomes a homogeneous layer of modified bitumen. This, in essence, yields the ultimate composite condition for a modified bitumen membrane—an interply weld composed of fused modified bitumen compound from both sheets.

Choices made easier

When cold adhesive or torching is used for membrane application instead of hot oxidized asphalt, a unique set of parameters is introduced. Torched and heat-welded multi-ply modified bitumen applications result in truly monolithic membranes. Modified bitumen sheets applied with cold adhesive become effectively monolithic and perform accordingly.

This can be demonstrated simply by trying to separate cured, cold-applied modified bitumen plies after conditioning in a freezer. Core cuts of modified bitumen sheets bonded with Type III or Type IV asphalt easily can be separated by hand at temperatures approaching 32 F (0 C). Most cold-adhered membranes, however, cannot be separated at temperatures approaching -40 F (-40 C).

Because of this tenacious interply bond strength, cold-adhesive and torched/heat-welded membrane systems exhibit superior fatigue resistances, coefficients of expansion, bond strengths and rooftop performances compared with oxidized asphalt-applied membranes.

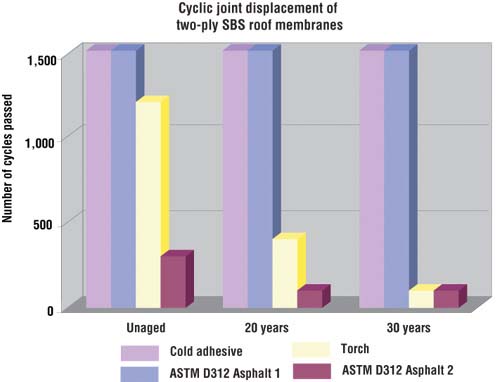

Figure 2 illustrates cyclic joint displacement results of identical two-ply, SBS, glass-reinforced membranes bonded by four methods: cold adhesive, torching and two ASTM D312 asphalts as shown in Figure 1. As in Figure 1, the membranes were tested before aging and after the heat-aging equivalent of 20 years and 30 years of field exposure. This test typically is terminated after 500 cycles, but the cold-adhesive and torch-applied membranes survived 1,500 cycles without failure. Neither membrane ruptures nor interply disbonding was observed. The oxidized-asphalt results from Figure 1 are included in Figure 2 for reference.

Figure 2: How identical SBS-modified bitumen membranes performed when bonded by cold adhesive, torching and two asphalts

When long-term performance is paramount, it is easy to see the advantages cold-adhesive and torched or heat-welded applications offer.

Tim Kersey is manager of technical development for Siplast, Irving, Texas. Kersey is the incoming chairman of ASTM Subcommittee D 8.04, Felts and Fabrics for Bituminous Roofing and Waterproofing.

COMMENTS

Be the first to comment. Please log in to leave a comment.