Of the three basic types of valley construction for asphalt shingle roof systems—open, closed-cut and woven—only open construction relies on metal valley lining for weatherproofing. With the other two construction types, shingles line the valley's center. However, recommendations differ regarding open valley installation on asphalt shingle roof systems.

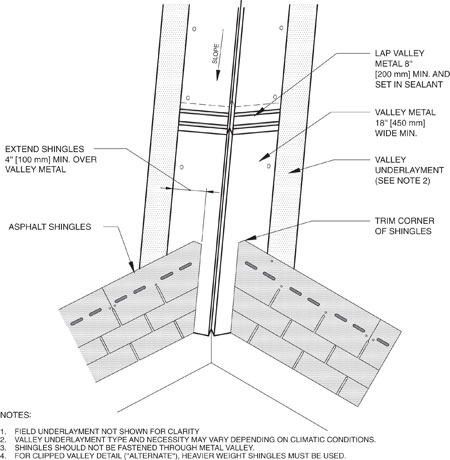

NRCA recommends open valley lining for use with asphalt shingle roof systems be formed from a minimum 18-inch-wide metal and include a center rib or splash diverter no less than 1 inch high. This configuration affords 8-inch flanges on either side of the center rib, which allows asphalt shingles to lap onto a flange at least 4 inches. Open valley metal thickness should be selected to match asphalt shingles' expected life.

In contrast, the Asphalt Roofing Manufacturers Association's (ARMA's) ARMA Residential Asphalt Roofing Manual, 2006 edition, recommends open valley flashing material be a 26-gauge galvanized metal or an equivalent corrosion-resistant, nonstaining material (such as copper or aluminum) and a minimum of 24 inches wide.

ARMA recommends having shingle ends lap the metal valley evenly on either side, leaving an open center channel 6 inches wide at the top of the valley and widening toward the bottom by 1/8 of an inch per foot of valley length. The minimum shingle overlap on each side of the metal valley should be 6 inches. Shingles trimmed to less than 12 inches in length should not be used to finish a course running into a valley.

Detail ASPH-6 from The NRCA Roofing and Waterproofing Manual, Fifth Edition

Additionally, ARMA recommends cementing the shingle end in the valley with asphalt roof cement 3 inches wide.

At least two asphalt shingle manufacturers' instructions agree with ARMA's recommended 24-inch width. At least one manufacturer recommends a 20-inch minimum width, and two manufacturers recommend an 18-inch minimum width. Two other asphalt shingle manufacturers do not recommend the use of open valleys with their products.

NRCA is concerned with ARMA's recommendations for open metal valleys on asphalt shingle roof systems. Shingles installed as recommended by ARMA would lap the open valley metal flanges without attachment by up to 9 inches at the top of the valley. The alternative—driving nails directly through the metal flanges—defeats the purpose of metal flashing.

Before you install open metal valleys on asphalt shingle roof systems, I encourage you to consult asphalt shingle manufacturers' recommendations.

Maciek Rupar is an NRCA director of technical services.

COMMENTS

Be the first to comment. Please log in to leave a comment.