Roof area dividers can perform important functions as parts of roof systems. For example, in regions where there are periods of freeze-thaw cycles, area dividers may be used to relieve thermal stresses on roof systems where expansion joints are not required. Additionally when reroofing is done in stages, area dividers can be used to separate roof system sections that differ in age or type. Area dividers also can be used to isolate a specific area on a roof system, such as damaged materials around an exhaust vent. Detail MB-9A, "Torch-applied Flashing at Area Divider in Roof System" in The NRCA Roofing Manual: Membrane Roof Systems—2007 provides recommendations for proper installation of area dividers.

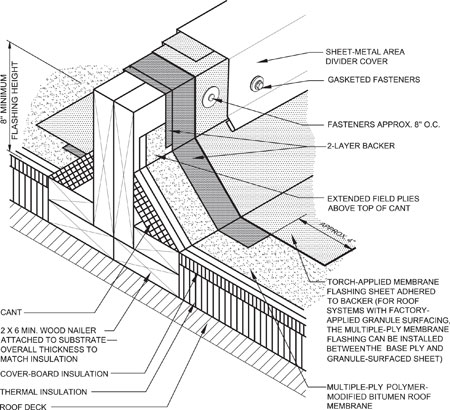

Detail MB-9A, The NRCA Roofing Manual: Membrane Roof Systems—2007

An area divider consists of a vertical double-wood curb that should be properly anchored to a roof deck. Horizontal wood nailers should be attached to the vertical nailers' base to provide lateral support and a location for attachment to the roof deck. The horizontal nailers should be equal in height to the insulation so a level transition exists from the insulation to the area divider. This allows for a more successful roof membrane installation. An area divider should not be installed on top of insulation; insulation will not provide adequate compressive strength to support an area divider.

Similar to all flashing installations, an area divider should extend a minimum of 8 inches above a finished roof system to provide adequate flashing height. Also, NRCA recommends an area divider be covered with a sheet-metal cover. Typically, a sheet-metal cover is attached on an area divider's vertical legs with exposed gasketed fasteners; cleats are needed unless unique aesthetic reasons exist.

Area dividers can be used with any roof system type though Detail MB-9A is specific to polymer-modified bitumen membranes. Polymer-modified bitumen membrane flashing sheets can be self-adhered, torch-applied, installed in moppings of hot asphalt or installed with cold adhesives. Detail MB-9A provides information regarding a torch-applied flashing installation.

Regardless of the application method, a polymer-modified bitumen membrane flashing consists of a flashing backer installed directly over a substrate and polymer-modified bitumen membrane flashing sheet adhered to the flashing backer. Flashing backers generally consist of one or two layers of ply sheet, base sheet or polymer-modified base sheet. Membrane flashing sheets are SBS- or APP-polymer-modified bitumen sheets.

More information regarding installation of polymer-modified membrane flashing sheets is provided in the Construction Details section of The NRCA Roofing Manual: Membrane Roof Systems—2007.

James R. Kirby, AIA, is NRCA's associate executive director of technical communications.

COMMENTS

Be the first to comment. Please log in to leave a comment.