During the past several years, use of the long-term thermal-resistance (LTTR) method for determining and reporting R-values for plastic foam insulation has been implemented and is gaining acceptance in U.S. and Canadian roofing markets. Although the LTTR method is viewed by many as a technical advancement, some roofing industry researchers have reservations with the methodology because results may not accurately represent the true thermal performance of the insulation products it tests.

Following is a summary of a research program in which NRCA participated. A work group tested R-values of aged insulation samples and compared results with the products' represented LTTR values.

Background

The technical basis for LTTR comes from ASTM C1303, "Standard Test Method for Estimating the Long-Term Change in the Thermal Resistance of Unfaced Rigid Closed Cell Plastic Foams by Slicing and Scaling Under Controlled Laboratory Conditions," which originally was published in 1995. In this test method, thermal resistance properties of thinly sliced specimens of plastic foam insulation material are tested and, from these data, long-term changes in thermal resistance are estimated. This methodology is reported to account for the diffusion of the blowing agent from the foam insulation's cells over time, resulting in a recognized reduction of thermal resistance of some plastic foam insulations as they age.

In Canada, ASTM C1303 was adapted into CAN/ULC-S770, "Standard for Determination of Long-Term Thermal Resistance of Closed-Cell Thermal Insulating Foams," in 2000. In CAN/ULC-S770, specimen preparation and analysis are based on ASTM C1303 and the actual thermal-resistance testing is conducted according to ASTM C518, "Standard Test Method for Steady-State Thermal Transmission Properties by Means of the Heat Flow Meter Apparatus." The CAN/ULC-S770 method is said to represent the thermal-resistance value of specimens tested after five years of storage in a controlled environment; this five-year figure corresponds closely to a 15-year, time-weighted average.

CAN/ULC-S770 is incorporated by reference in the 2001 editions of Canadian standards for polystyrene, polyisocyanurate and spray polyurethane foam insulation: CAN/ULC-S701, "Standard for Thermal Insulation, Polystyrene, Boards and Pipe Covering;" CAN/ULC-S704, "Standard for Thermal Insulation, Polyurethane and Polyisocyanurate, Boards, Faced;" and CAN/ULC-S705.1, "Standard for Thermal Insulation—Spray Applied Rigid Polyurethane Foam, Medium Density Material—Specification."

In the U.S., the CAN/ULC-S770 methodology was adapted to and incorporated into the 2002 edition of ASTM C1289, "Standard Specification for Faced Rigid Cellular Polyisocyanurate Thermal Insulation Board." Beginning in January 2003, the LTTR method of testing and reporting R-values was adopted by most polyisocyanurate insulation manufacturers in the U.S.

A research group found published LTTR values for certain products to be over-reported.

Testing

Based on concerns raised by some researchers regarding a bias in the LTTR methodology, a work group was formed consisting of representatives from the Canadian Roofing Contractors Association (CRCA), Extruded Polystyrene Foam Association and NRCA to conduct limited research addressing the subject. This research consisted of testing the thermal resistance of aged, stored, plastic foam insulation and comparing the results with published LTTR values.

Samples of plastic foam insulation were obtained by CRCA and NRCA through typical distribution sources. Older, aged samples were taken from stock left over from other research projects that had been stored in controlled laboratory conditions.

The ages of the samples were determined using the date of manufacture indicated on product wrappers, labels and product imprint markings. For several product samples (samples 5, 6, 11, 12 and 19), the product markings did not clearly indicate product manufacturing dates. Samples 5, 6, 11 and 12 were procured more than two years (a minimum of 730 days) before testing. Sample 19 was procured more than 10 months (a minimum of 300 days) before testing.

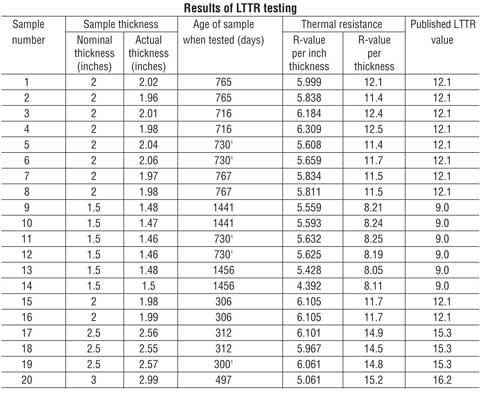

The samples were provided to R & D Services Inc., Cookeville, Tenn., a laboratory recognized for its thermal-performance testing and expertise, for R-value testing. The R-value testing was conducted according to ASTM C518. Data from this research is provided in the table.

Seventeen of the 20 samples tested exhibited R-values less than their established LTTR values. All these samples were less than five years old, the relative age the LTTR methodology is intended to represent. Four of the samples with R-values less than the established LTTR values were less than one year old.

On the basis of this data, a positive bias in the LTTR methodology clearly is apparent—that is, the LTTR methodology appears to overstate a product's actual R-value at five years of relative aging.

Follow-up actions

Representatives of the work group will be sharing this data and its conclusion with the CAN/ULC-S770 task group and ASTM C1303 task group. Both task groups are encouraged to address the apparent positive bias in the current LTTR methodology in future revisions of the standards.

Specifiers who use LTTR methodology should be aware of this apparent positive bias and careful not to overstate or over-represent these products' actual R-values.

Mark S. Graham is NRCA's associate executive director of technical services.

COMMENTS

Be the first to comment. Please log in to leave a comment.