The spray polyurethane foam (SPF) industry has been active in the standards development arena, and, within the past couple of years, two new ASTM International standards have been released that directly relate to SPF roof systems. Roofing professionals need to understand which standards currently exist and the new standards' implications.

ASTM D7119, "Standard Guide for Sampling Spray Polyurethane Foam and Coating in Roofing," was approved in 2007 and provides guidelines for the field removal of test specimens from new or existing SPF roof systems. It describes the types and purposes of sample cuts, visual inspection techniques, laboratory physical property tests, and repair procedures for core and slit sample holes.

ASTM D7425, "Standard Specification for Spray Polyurethane Foam Used for Roofing Applications," was approved in 2008 and provides types and physical properties of SPF used in roof systems.

Two previously existing ASTM International standards applicable to SPF roof systems are ASTM C1029 and ASTM D5469.

ASTM C1029, "Standard Specification for Spray Applied Rigid Cellular Polyurethane Thermal Insulation," originally was approved in 1985 and provides types and physical properties of SPF used as thermal insulation. ASTM C1029, Types III and IV, are used in SPF roof systems though Type III is most common.

ASTM D5469, "Standard Guide for Application of New Spray-Applied Polyurethane Foam and Coated Roofing Systems," originally was approved in 1993 and provides requirements for the application of new SPF roof systems with elastomeric coatings and optional mineral granules. This standard does not apply to retrofit or re-cover roof systems.

Although ASTM C1029 and ASTM D5469 have been used for some time and are familiar to the SPF industry, the introduction of ASTM D7119 and ASTM D7425 may spark some confusion.

Two material standards

With the recent development of ASTM D7425, the SPF industry now has two distinct material standards; however, ASTM D7425 specifically addresses the types and physical properties of SPF used in roofing, and ASTM C1029 specifically addresses the types and physical properties of SPF used as thermal insulation.

ASTM D7425 was developed to simplify and clarify requirements for SPF used as a roofing material. Some would argue that SPF is used in a roof system as insulation; therefore, a standard for SPF as thermal insulation is adequate. Others believe that because SPF also is used as a roof membrane, a standard for SPF used in roofing is needed. Another issue is where a standard resides within the ASTM International organization: Is an SPF standard relevant to roofing more appropriately developed by an insulation committee or roofing committee?

Physical properties of spray polyurethane foam

Each material standard provides requirements for the SPF material in its completed form (after being sprayed). These standards do not provide minimum requirements for the individual components (such as A-side and B-side, or isocyanate and polyol, respectively) in liquid form.

ASTM C1029 classifies SPF into four types based on compressive strength. ASTM D7425 classifies SPF into two types based on R-value and closed-cell content. Currently, building codes and NRCA recommend SPF used in roof systems comply with ASTM C1029, Class III, which requires a minimum compressive strength of 40 pounds per square inch.

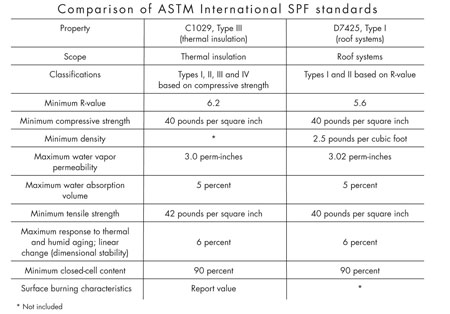

When comparing the physical properties of SPF meeting ASTM C1029, Type III, with the physical properties of SPF meeting ASTM D7425, Type I, a few important differences are noteworthy.

First, the minimum required R-value has changed. A more realistic R-value of 5.6 is specified in ASTM D7425 as compared with a minimum R-value of 6.2 in ASTM C1029. All closed-cell foam insulations rely on trapped gases to provide thermal resistance. If the trapped gas is air, the insulation will have an R-value of about 5. If the trapped gas has a greater thermal resistance than air, the R-value will increase. However, over time, these gases escape and are replaced with air, reducing R-value.

NRCA continues to recommend that design R-value for the most commonly used closed-cell insulation, polyisocyanurate, be 5.6. ASTM D7425's use of 5.6 as the R-value is a positive step toward a realistic long-term design R-value for SPF used in roofing.

Also, density is now a specific requirement in ASTM D7425. Those who developed this standard believe SPF used for roofing will achieve a minimum density when other physical properties are met, such as compressive strength. Minimum compressive strength requirements are equal in the material standards.

Additionally, water vapor permeability, water absorption, tensile strength, response to thermal and humid aging (dimensional stability, for example), and closed-cell content requirements are equal in the material standards.

Surface burning characteristic is an important trait of uncoated SPF; uncoated SPF primarily is used for interior insulating purposes but not for roofing purposes. SPF used for roofing typically is coated but also can be covered with some single-ply membranes. Appropriately, ASTM D7425 does not include a requirement for surface burning characteristics.

Industry implications

What does having two material standards mean for the SPF industry? Developing an SPF material standard specific to roofing as an attempt to simplify and clarify requirements for SPF used as a roofing material is merely an initial step in the process.

For a material standard to take hold in an industry, it must begin to be included in the fundamental drivers, guidelines and recommendations of that industry. That means building codes have to adopt it; specifier groups need to embrace it and include it in specifications; and the industry's trade groups need to begin including the new standard in their guidelines.

But what will happen during the interim while the industry has two similar but not equal material standards? The 2009 International Code Council's (ICC) building codes are essentially complete; they are waiting for publication and release. Therefore, the first true opportunity for a new SPF material standard to be included in the pages of an ICC document is 2012; similarly, the first opportunity to be included in The NRCA Roofing Manual is 2012 when the next volume about SPF roof systems is released.

I am unaware whether and when specifier groups such as RCI Inc., The Construction Specifiers Institute Inc. and The American Institute of Architects will begin to use ASTM D7425. The use of this material standard by specifier groups likely will parallel its inclusion in building codes. Additionally, there are other ASTM International standards that reference ASTM C1029 that will need to be updated so there are not legal ramifications for installers.

One aspect of this is the burden on material manufacturers. Fortunately, the SPF materials used for roofing that manufacturers produce likely will meet both standards because of the standards' similarity. To assist the industry in this transition, it is desirable for manufacturers to test and label their materials as meeting ASTM C1029 and ASTM D7425.

The best hope for the inclusion of ASTM D7425 is the slow attrition of ASTM C1029 throughout building codes, specifier groups and the construction industry. This will require a dedicated approach toward the long-term goal of inclusion that the SPF industry has for ASTM D7425. The Spray Polyurethane Foam Alliance (SPFA) is duly positioned to be the bearer of this responsibility if its members favor the new material standard versus the existing material standard.

ASTM process

ASTM International's standards development process bears partial responsibility for the SPF industry having two SPF material standards.

Within ASTM International, standards development is divided into many main committees. ASTM C16, Committee on Thermal Insulation, and ASTM D08, Committee on Roofing and Waterproofing, address insulation standards and roofing and waterproofing material standards, respectively. Additionally, each main committee is composed of many subcommittees that address specific segments within the general subject area covered by the main committee.

For example, within the ASTM D08 committee, the D08.06 Subcommittee, Spray Polyurethane Foam Roof Systems, is responsible for the development of SPF standards relating to roofing.

And within the ASTM C16 committee, the C16.22 Subcommittee, Organic and Nonhomogenous Inorganic Thermal Insulations, is responsible for the development of insulation standards, many of which relate to insulation used in roof systems.

One of the reasons an SPF material standard was developed within the ASTM D08 committee is to remove participants who focus on insulation rather than roofing. It is assumed a roofing focus will result in a better standard for SPF used in roofing. The D08.06 subcommittee believed it appropriate to duplicate efforts to have a simplified SPF material standard.

One of my main concerns is the intentional duplication of material standards. Is it ASTM International's responsibility to manage the overall standards development? Yes. Is it the SPF industry's responsibility to manage the development of its standards? Yes. In my opinion, one of the key reasons ASTM International exists is to provide oversight to prevent duplicate standards from being developed. At a minimum, ASTM International should manage the process so segments of the roofing and insulation industries are not seemingly at odds with one another.

Perhaps this is not ASTM International's role, but who better to do it?

ASTM D7425 and ASTM C1029 were approved in 2008. ASTM International standards stay on the books for seven years before requiring re-approval. This means the industry will have two SPF material standards for the next seven years.

The SPF industry also bears responsibility for the duplication of ASTM International material standards, as well as the new sampling standard that duplicates portions of the NRCA/SPFA quality-control document. In my opinion, the SPF industry and ASTM International are better off spending time developing additional standards for materials currently used in SPF roof systems, such as polyurea and two-part polyurethane coatings.

ASTM International standards frequently become legal documents by incorporation into building codes or project specifications. We need to carefully consider the ramifications of the development of new ASTM International standards. And we also should realize that sometimes additional standards simply are not necessary.

Sampling and application

The other new standard, ASTM D7119, puts forth sampling procedures for core cuts and slit samples and is intended to standardize what has been occurring in the SPF industry for some time. NRCA and SPFA always have had and still have essentially equivalent sampling guidelines.

Sampling of SPF roof systems is done for two reasons. It is used as a quality-control measure by contractors, and it is used as a quality-assurance measure by third-party observers that typically represent building owners. ASTM D7119 essentially defines the process of removing samples, the frequency of removing samples, how they might be analyzed and their repair.

Core and slit samples are effective methods for roofing contractors to perform quality control during SPF roof system installation. However, NRCA strongly believes core and slit samples should not be used for quality assurance and instead considers full-time observation the best, most effective method of third-party quality assurance. The NRCA/SPFA Quality Control Guidelines for the Application of Sprayed Polyurethane Foam Roofing provides guidelines for on-site evaluation of SPF roof systems during installation.

Unfortunately, I can foresee ASTM D7119 being used by third-party inspectors as a means to invalidate a roofing contractor's quality-control procedures (that is, to dispute the acceptability of an SPF roof system) rather than being used as intended: as a guide to removing and repairing samples.

On the other hand, ASTM D5469 addresses new SPF roof system installations. It's been used in the industry for nearly 15 years. It is my opinion that we should not reinvent this standard; let's only continue to monitor and update it wisely. I believe the SPF industry feels the same way.

However, by all rights, ASTM International's SPF subcommittee should propose to include a reference to ASTM D7119 in the application standard to ensure users of ASTM D5469 are removing and repairing samples according to an ASTM International standard.

A transition

You should be aware of the existing ASTM International standards that apply to SPF roof systems. And you shouldn't be surprised to see a new SPF material standard, ASTM D7425, referenced in upcoming specifications.

Let's hope the transition to the new SPF material standard is smooth and without confusion. With the SPF industry's help and dedication to this issue, it is possible to reduce some of the confusion that is likely to ensue.

James R. Kirby, AIA, is NRCA's associate executive director of technical communications.

COMMENTS

Be the first to comment. Please log in to leave a comment.