Vegetative roof systems, sometimes referred to as "green roofs," are rapidly gaining popularity and acceptance in the U.S. For many, the appeal of vegetative roof systems involves their aesthetics and environmental attributes, including reduced storm water runoff, air-quality improvement, mitigation of heat island effects and noise reduction for building occupants.

However, vegetative roof systems' compliance with U.S. building codes is questionable. Although vegetative roof systems' waterproofing components can be tested and evaluated for code compliance bythe same means used for conventional roof systems, vegetative roof systems' growth media and plants largely have been untested for the purposes of code compliance.

Because growth media and plants serve as the topmost surface of most vegetative roof systems, these components are an important consideration in determining vegetative roof systems' wind resistances.

For example, the 2006, 2009 and upcoming 2012 editions of the International Building Code (IBC) restrict the use of aggregate surfacing on roof systems based on maximum building height, basic wind speed and exposure category for the building being evaluated. This restriction is based on the concern that aggregate could scour and become wind-borne debris during high-wind events. For additional information regarding IBC's restrictions on the use of rooftop aggregate, see "What will happen to aggregate?" August 2004 issue, page 61.

Much of the growth media used for vegetative roof systems is composed of lightweight aggregate and particles that are lighter in density and usually smaller in size than aggregate used for surfacing or ballast. NRCA is concerned about vegetative roof systems' growth media and plants scouring and becoming wind-borne debris.

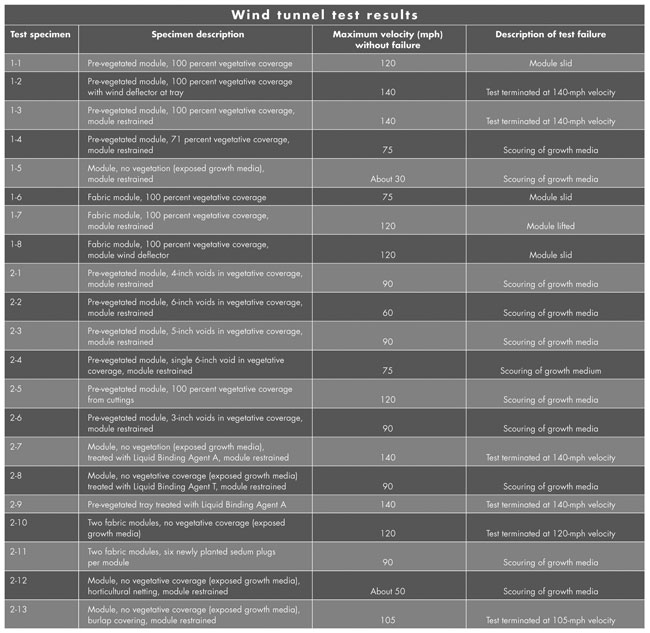

Test specimen descriptions, maximum test velocities without failure and descriptions of test failure

NRCA's concern regarding building code compliance of vegetative roof systems is exacerbated because the vegetative roof system industry is doing little research or testing to address such systems' wind resistances.

To provide some fundamental data associated with wind resistances and scouring of vegetative roof systems' growth media and plant layers, NRCA recently participated in a limited testing program at Southern Illinois University Edwardsville (SIUE). SIUE has conducted a significant amount of research regarding vegetative roof systems and made an on-campus wind tunnel available to NRCA.

Also assisting in the testing program were Green Roof Blocks, Lake Saint Louis, Mo., and Jost Greenhouses, St. Louis, which provided the vegetative roof system materials tested.

NRCA testing

SIUE's wind tunnel is a custom-designed, subsonic, recirculating wind tunnel that operates as a closed loop with a two-stage axial flow fan driven by a 300-horsepower electric motor. The wind tunnel's test specimen bed measures 6 feet long by 30 inches wide by 24 inches high. The wind tunnel was manufactured by Engineering Laboratory Design Inc., Lake City, Minn.

SIUE uses the wind tunnel for educational and research purposes.

For NRCA's testing, to minimize the potential of debris recirculating in the wind tunnel's airstream, a metal screen was placed about 8 feet from the downstream edge of the wind tunnel's test specimen bed. With the metal screen in place, the wind tunnel's fan was calibrated to generate test velocities at the specimen test bed up to 140 mph.

Twenty-one vegetative roof system specimens were tested in the wind tunnel. Each specimen contained growth media consisting of lightweight aggregate and organic content at an approximate 4-to-1 ratio. The lightweight aggregate was a nominal 3/8 of an inch in size and had a bulk dry loose density ranging from 38 pounds per cubic foot (pcf) to 70 pcf. The organic content primarily consisted of decomposing pine bark. Plants were a mixed variety of sedum.

The figure provides descriptions of the test specimens, maximum test velocities before failure and descriptions of the failure modes for each specimen tested.

Results

Pre-vegetated modules (Test Specimens 1-2 and 1-3) with 100 percent vegetative coverage (meaning they had no exposed growth media) that were tethered in the test specimen bed to restrain them from sliding successfully withstood a tested velocity of 140 mph. At about 120 mph, a similar unrestrained module (Test Specimen 1-1) slid in the test specimen bed, which was considered a failure. The module measured 24 inches by 24 inches by 4 inches thick and weighed about 66 pounds.

The 140-mph test velocity without scouring is significant because it indicates relatively high wind-resistance values are possible with vegetative roof systems under certain ideal conditions. Realistically, 100 percent vegetative coverage, such as that of the module tested, is not readily achievable in the field. Eighty percent vegetative coverage is a target figure oftentimes used as an acceptable threshold for vegetative coverage after an establishment period.

In contrast, Test Specimen 1-5, which had no vegetative coverage (meaning it had fully exposed growth media), experienced significant scouring of its growth media at a test velocity of about 30 mph. This illustrates exposed growth media is susceptible to wind scour and becoming wind-borne debris at relatively low wind speeds.

A number of test specimens with various vegetative coverages were tested to attempt to determine a maximum test velocity for a module with reasonable coverage. A restrained, pre-vegetated module (Test Specimen 2-1) with vegetative coverage and 4-inch voids (areas of exposed growth media) successfully achieved a 90-mph test velocity. This scenario appears to be a useful reference point because IBC uses 90 mph as the basic wind speed for a majority of the U.S.

Also tested were several modules with no vegetative coverage that had been treated with proprietary liquid binding agents, often called "tackifiers." The landscaping industry sometimes uses tackifiers to stabilize embankments, such as highway embankments, until landscaping can take root and mature.

Although such tackifiers are not currently marketed for vegetative roof systems, they appear to hold some promise: Test Specimen 2-7 successfully achieved a test velocity of 140 mph without scouring. However, the other tackifier-treated module tested (Test Specimen 2-8) only achieved a 90-mph test velocity, illustrating tackifier formulation and application are important considerations.

Also, two modules with no vegetative coverage and horticultural netting were tested. Test Specimen 2-13 successfully achieved a 105-mph test velocity, and the other, Test Specimen 2-12, only achieved about a 50-mph test velocity. Provided a satisfactory means of securely attaching horticultural netting can be designed, horticultural netting may be a practical approach to minimizing growth media scour and wind-borne debris during the plant establishment period.

Closing thoughts

NRCA conducted wind tunnel testing of vegetative roof system specimens to provide fundamental data and concepts addressing growth media's potential to scour and become wind-borne debris.

The data derived from this test program is not intended to be a definitive assessment. Instead, it is intended to be a starting point for the vegetative roof system industry to conduct the testing and research necessary to determine vegetative roof systems' wind resistances. Such information is important for installing code-compliant vegetative roof systems.

When evaluating the data from this test program, it is important to realize no attempt has been made to correlate the test velocities from SIUE's wind tunnel with IBC's basic wind speed and other wind design conditions, including building height, exposure category, and roof area perimeter and corner conditions.

Mark S. Graham is NRCA's associate executive director of technical services.

COMMENTS

Be the first to comment. Please log in to leave a comment.