As you are aware, asphalt-saturated and asphalt-impregnated felt underlayments are the most common steep-slope roof underlayments. These types of underlayments are appealing because of their ease of installation, ability to perform intended functions and relatively low cost.

A steep-slope roof system underlayment performs several functions, such as:

Also widely available are synthetic and composite products often touted by manufacturers as being stronger, lighter or better weathering alternatives. The following will examine current standards and building code requirements for underlayments used with steep-slope roof systems.

Product description and standards

Asphalt-saturated and asphalt-impregnated felt, commonly called "asphalt felt" or "felt paper," use an organic reinforcing mat, inorganic reinforcing mat or combination organic mat reinforced with inorganic fiber. Underlayments are reinforced with mats designed to support the asphalt. Reinforcing mats of different thicknesses are used to produce underlayments of different weights.

For asphalt-saturated felt underlayments, there are three applicable ASTM International standards: ASTM D226-06, "Standard Specification for Asphalt-Saturated Organic Felt Used in Roofing and Waterproofing"; ASTM D4869-05e1, "Standard Specification for Asphalt-Saturated Organic Felt Underlayment Used in Steep Slope Roofing"; and ASTM D6757-07, "Standard Specification for Underlayment Felt Containing Inorganic Fibers Used in Steep Slope Roofing." These standards appear in the Referenced Standards chapters of the 2012 International Building Code® (IBC 2012) and 2012 International Residential Code® (IRC 2012).

Some types of asphalt felt underlayments can wrinkle and buckle if allowed to become wet before roof covering installation. Also, asphalt felts cannot tolerate long-term exposure and generally should be covered as soon as possible after installation.

Synthetic sheet underlayments are produced with polyolefin-based resins, such as polyethylene and polypropylene, recycled rubber and/or similar components that do not fit into the organic or inorganic felt underlayment classifications. Synthetic underlayments generally are characterized as being lightweight and having high-tensile strength, long-term ultraviolet resistance, low or no moisture absorption, and low shrinkage and wrinkling. Thickness, tensile strength and abrasion resistance for synthetic sheet underlayments vary. Some synthetic sheet underlayments have a relatively low permeance rating—lower than those for organic and inorganic asphalt felt underlayments—and, therefore, may function as vapor retarders.

There currently are no ASTM International standards that apply to synthetic sheet underlayments, and this type of product is not referenced as an underlayment in IBC 2012, IRC 2012 or any of the earlier editions of these building codes.

Code compliance

The fact a specific design, material or method of construction is not addressed in the code does not indicate code developers intend to prohibit them. A building official is expected to apply sound technical judgment when accepting alternative construction designs, materials and methods that can offer equivalent performance required by the code. A building official is responsible for determining whether a requested alternative provides the equivalent level of protection of public health, safety and welfare as required by the code.

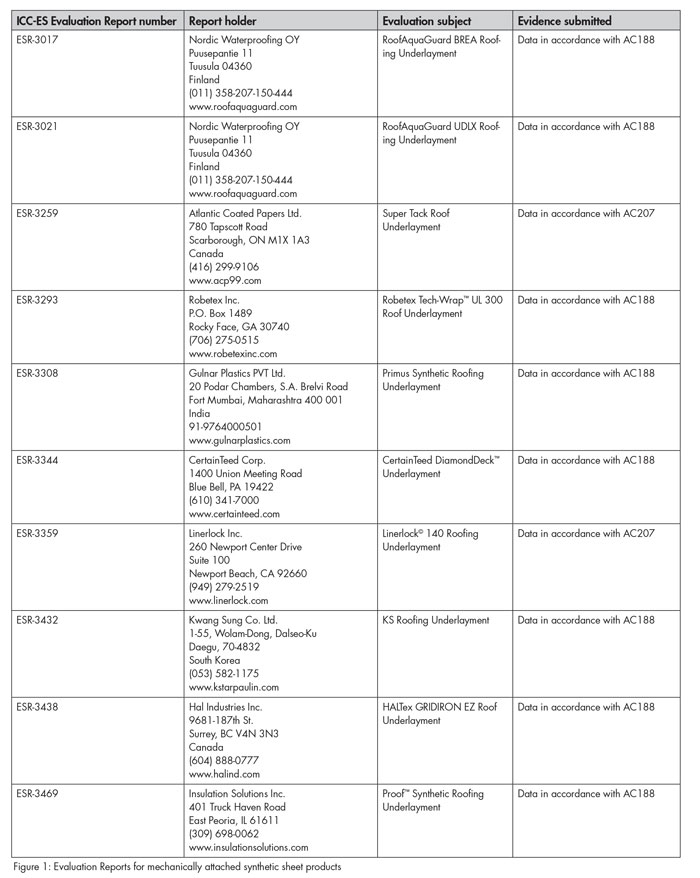

Figure 1: Evaluation Reports for mechanically attached synthetic sheet products

In IBC 2012, provisions for the evaluation and acceptance of alternative designs, materials and methods of construction are addressed in Chapter 1—Scope and Administration, Section [A] 104.11 Alternative Materials, Design and Methods of Construction and Equipment. This section gives building officials authority to accept alternative construction designs, materials and methods provided they are determined by a building official to meet the code's intent. When making this determination, a building official may request the party proposing the alternative provide evidence in the form of research reports or test data, which are explained in Section [A] 104.11.1 and Section [A] 104.11.2, respectively.

Section [A] 104.11 is intended to be applied on a job-by-job basis. It is assumed a building official will make a determination based on the conditions of a particular project and the totality of the proposed construction. A material may be deemed acceptable in one instance but not necessarily in another situation or by another building official. Similar (though not identical) language appears in IRC 2012 and earlier editions of IBC and IRC.

ICC Evaluation Service

A subsidiary of the International Code Council (ICC), the body that develops IBC and IRC, ICC Evaluation Service (ICC-ES) provides technical evaluations of alternative construction designs, materials and methods for code compliance and compliance with a code's intent. ICC-ES has developed Acceptance Criteria for evaluating alternative designs, materials and methods of construction that are not already specifically permitted by the code. The outcome of an ICC-ES evaluation is an Evaluation Report.

There are two relevant Acceptance Criteria for synthetic underlayments: AC188, "Acceptance Criteria for Roof Underlayments," and AC207, "Acceptance Criteria for Polypropylene Roof Underlayments." The current versions of AC188 and AC207 were approved in February 2012; both have an April 1, 2013, compliance date. Products for which evaluations were conducted in accordance with earlier versions of AC188 and AC207 have until the compliance date to demonstrate compliance with current versions of the acceptance criteria.

AC188 and AC207 list evaluation for use with fire-classified roofing material as optional. If reports of a roof classification test conducted in accordance with ASTM E108 or UL 790 were submitted as part of the evaluation process, fire classification information will be listed in the Evaluation Report for those products.

At press time, there are 11 Evaluation Reports available from ICC-ES's website, www.icc-es.org, that comply with the most recent versions of AC188 or AC207 and IBC 2012 and IRC 2012. Also, all 11 reports indicate the products described are intended for use as an alternative to ASTM D226, Type I and Type II, roof underlayments specified in IBC Chapter 15 and IRC Chapter 9. Because underlayment material for all roof covering types in IBC 2012 and IRC 2012 reference ASTM D226, Type I or Type II, as an acceptable underlayment material standard, products listed in the Evaluation Reports are deemed acceptable underlayment alternatives per ICC-ES.

Ten of the 11 Evaluation Reports are for mechanically attached synthetic sheet products (see Figure 1).

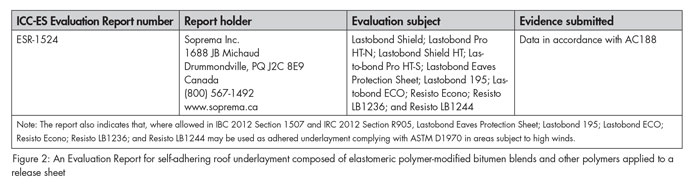

One Evaluation Report is for self-adhering roof underlayments composed of elastomeric polymer-modified bitumen blends and other polymers applied to a release sheet (see Figure 2).

Figure 2: An Evaluation Report for self-adhering roof underlayment composed of elastomeric polymer-modified bitumen blends and other polymers applied to a release sheet

Evaluation Reports are approved and posted on ICC-ES's website on an ongoing basis. Each report contains conditions of use statements that must be followed for the products described in the Evaluation Reports to be considered suitable alternatives to what the code specifies.

Finally, there are many more Evaluation Reports for alternative underlayments that comply with earlier versions of AC188 and AC207 and earlier versions of the building code. If a subject building is located in a jurisdiction that has adopted an older code, there may be relevant Evaluation Reports not mentioned in this article.

Final thoughts

The number of synthetic underlayment products submitted for ICC-ES evaluation represents a mere fraction of the available synthetic underlayment products. Also, because synthetic underlayments currently are not addressed by a consensus standard such as those developed by ASTM International, these products can be difficult to evaluate or compare. Even those products deemed as an acceptable equivalent to products in the code should be considered as meeting only a minimum requirement.

Jason P. Wilen, AIA, CDT, RRO, is an NRCA director of technical services.

Did you know?

NRCA offers publications that explain IBC requirements applicable to roofing, including the evaluation and acceptance of alternative designs, materials and methods of construction. Visit shop.nrca.net for more information.

COMMENTS

Be the first to comment. Please log in to leave a comment.