The NRCA Roofing Manual: Architectural Metal Flashing, Condensation and Air Leakage Control, and Reroofing—2014 was released in January and updates and replaces The NRCA Roofing Manual: Architectural Metal Flashing, Condensation Control and Reroofing—2010. It completes the four-volume set of The NRCA Roofing Manual series for 2011-14. Other current volumes in The NRCA Roofing Manual include The NRCA Roofing Manual: Membrane Roof Systems—2011; The NRCA Roofing Manual: Metal Panel and SPF Roof Systems—2012; and The NRCA Roofing Manual: Steep-slope Roof Systems—2013.

NRCA develops The NRCA Roofing Manual as a best-practices guide for roof system installations on buildings and other structures in North America. The manual's guidelines are based on the recommendations of NRCA's Technical Operations Committee and NRCA's Manual Update Committee. NRCA's Technical Operations Committee establishes NRCA's technical programs and priorities. NRCA's Manual Update Committee is responsible for updating The NRCA Roofing Manual. The committees are composed of knowledgeable, practicing roofing professionals.

NRCA's best-practice approach generally is more conservative than building codes' minimum requirements and is consistent with or more conservative than manufacturers' recommendations. Building codes provide minimum legal requirements for construction, and manufacturers' recommendations generally provide a level of quality construction necessary to obtain a manufacturer's warranty. The NRCA Roofing Manual should be viewed as a guide and not a design or installation standard or code.

New manual at a glance

As indicated in the title, the 2014 volume specifically provides recommendations for air leakage control in roof assemblies. NRCA's newly developed air leakage control guidelines address 2012 I-code requirements for building envelope air leakage control. The new content is among the revisions in the section titled Condensation and Air Leakage Control, formerly titled Condensation Control.

As the final volume in the current set, the new manual benefits from the previous years' work by NRCA's Manual Update Committee. A significant number of revisions within the 2014 manual resulted from revisions the committee introduced in the earlier three volumes.

For example, NRCA's updated recommendations for addressing dissimilar metal contact in metal panel roof systems—originally introduced in the 2012 volume—were incorporated as part of the current volume's Architectural Metal Flashing section. Also, because roof re-cover design guidelines were included as part of roof system type-specific sections in other volumes of the current manual, the roof re-cover design guidelines chapter that was part of the 2010 volume is not present in the current volume.

In more detail

The Architectural Metal Flashing section is intended to supplement other volumes' treatments of flashings with in-depth technical information concerning the design and installation of architectural sheet-metal components of low-slope and steep-slope roof system flashings.

For instance, an edge metal profile included as part of a raised perimeter detail for a membrane roof system in the 2011 manual is available as a separate construction detail in the Architectural Metal Flashing section. The detail may be dimensioned in-house and used as a shop drawing for a specific project. Metal panel roof systems are the exception—the Metal Panel section of The NRCA Roofing Manual: Metal Panel and SPF Roof Systems—2012 provides extensive information about metal panel roof system flashings. Architectural Metal Flashing text also has been reorganized to make locating information more intuitive.

As part of an overview of roofing metals in Chapter 1—Guidelines Applicable to Metal, metal gauge and weight information now is available at the end of each section and addresses a specific metal for convenient use. Language addressing weather and corrosive environmental effects on roofing metals was similarly incorporated where it may be easily located. In addition to an updated and expanded discussion of galvanic corrosion, soldering and welding is addressed in new text in addition to a table-format guide.

Chapter 2—Guidelines Applicable to Low-slope Roof Systems and Chapter 3—Guidelines Applicable to Steep-slope Roof Systems include a significant volume of content previously located in the construction details chapter. Joinery and securement isometric drawings formerly provided as construction details appear as figures within the text of revised Chapters 2 and 3. The constructions recast in this manner include common options for coping and fascia joinery and securement; counterflashing end-lap joinery and securement; expansion joint cover joinery and securement; and joining externally attached gutter sections. Also, sheet-metal flashing joints are not shown on revised construction details in Chapter 4—Construction Details. The rearrangement of this content is intended to make the manual more user-friendly—readers are able to see the illustrations alongside the text that addresses the constructions.

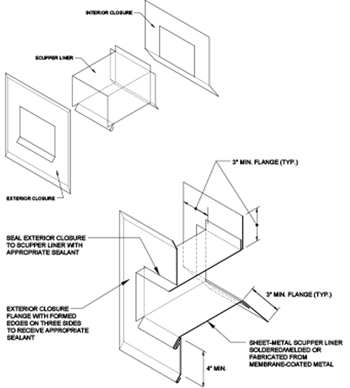

Speaking of construction details, there are 59 architectural metal flashing details in the new manual, an increase from 48 in the 2010 manual. Each detail depicts a single sheet-metal component—joinery and securement options having been relocated, as previously noted. A number of construction details were redrawn for clarity or to better illustrate the amount of attention to detail demanded by sheet-metal flashing work. For example, scupper details include exploded views of the assemblies as shown in Figure 1.

Figure 1: Overflow scupper detail

Four new sheet-metal gutter details are available—a pair for low-slope applications and a second pair for steep-slope applications.

Revised coping and edge metal details illustrate ANSI/SPRI ES-1-tested shapes for which NRCA has obtained approval listings from third-party certification agencies. Updated text in the introduction to Chapter 4—Construction Details provides background information about the approval listing programs NRCA maintains for the ES-1-tested shapes with Intertek Group, Underwriters Laboratories LLC and FM Global.

Construction details in the Architectural Metal Flashing section previously were labeled "SM-" for sheet metal. Now, the details use labels that designate specific constructions. For example, "C-" for coping; "CH-" for chimney; "FC-" for fascia; and "V-" for valley.

Tables with expansion coefficients of metals and metal gauge, thickness and weight information are provided in Architectural Metal Flashing appendixes.

Air leakage

Roof system vapor retarder design is a frequent subject of questions submitted to NRCA's Technical Services Department. Recently, NRCA also has been receiving questions about roof system air retarder design. It has been NRCA's experience the two subjects are not well-understood and are being confused by a large proportion of callers. One reason likely contributing to this is the scarcity of technical guides published for the roofing industry.

When updating the renamed Condensation and Air Leakage Control section, NRCA's Manual Update Committee took on the challenge of sorting out the confusion associated with vapor and air retarders from the perspective of a roof system designer. NRCA enlisted the help of Wayne Tobiasson, a former senior research civil engineer for the U.S. Army Corps of Engineers' Cold Regions Research and Engineering Laboratory (CRREL), for a review of the revised section. Tobiasson is recognized for his expertise in building technology with emphasis on controlling moisture in roof systems.

Although controlling condensation and air leakage in buildings is not the responsibility of roofing contractors, NRCA includes this section in The NRCA Roofing Manual to provide background information regarding condensation issues in buildings. NRCA recognizes it is urgent to articulate its recommendations for air leakage control because air leakage control requirements applicable to roof assemblies are provided in the International Energy Conservation Code,® 2012 Edition (IECC 2012), which an increasing number of U.S. jurisdictions are adopting.

The Condensation and Air Leakage Control section incorporates references to IECC 2012 and the International Green Construction Code,® 2012 Edition (IgCC 2012) language addressing air leakage in building assemblies. The referenced code language is—or likely is soon to be—part of locally adopted building codes in U.S. jurisdictions. This section provides NRCA's recommendations for complying with code air leakage provisions applicable to roof assemblies.

Discussion of moisture vapor movement principles in Chapter 1—Fundamentals of Condensation and Air Leakage Control provides expanded information about air leakage in buildings.

Chapter 2—Condensation Control for Low-slope Roof Systems provides two sets of guidelines for determining the need for a vapor retarder in a low-slope roof assembly. Along with NRCA guidelines, CRREL guidelines developed for low-slope roof systems with adhered membranes are included. Roof system designers may use CRREL's guidelines for roof systems with mechanically attached membranes that are provided with effective air retarder systems.

Chapter 3, which addresses steep-slope roof assemblies, is expanded with sections addressing air sealing of ceilings, attic and rafter space insulation, and ceiling vapor retarders for buildings with ventilated attic or rafter space assemblies. Although these items typically are outside the scope of roofing work, NRCA has included the information because moisture vapor transport in attic and rafter space assemblies over conditioned space affects the effectiveness of attic and rafter space ventilation. In cold climates, moisture-sensitive components of steep-slope roof assemblies over ventilated attics or rafter space assemblies may be at risk of deterioration if they are not provided with adequate moisture vapor transport control.

Also, discussion of unvented attics references revised model code provisions for conditioned attic assemblies. The applicable code language in the International Residential Code,® 2012 Edition has changed somewhat from the 2009 edition.

Chapter 4—Air Retarders for Roof Assemblies is new to the manual this year. This chapter focuses on air leakage provisions for roof assemblies in IECC 2012 and associated design considerations.

Some codes and many test standards use the term "air barrier" though they provide prescriptive requirements for controlling air leakage within specific measurable rates. Effectively, the codes acknowledge it is impossible to create an absolute barrier to air leakage using accepted construction methods but use a term that suggests otherwise. NRCA prefers to use the term "air retarder" when referring to materials and constructions intended to control air leakage through a building's envelope to code-prescribed levels.

Chapter 4 addresses compliance options available to roof system designers under I-code provisions for air leakage control.

IECC 2012 and IgCC 2012 provide prescriptive requirements for controlling air leakage through roof assemblies. The codes primarily are concerned with reducing building energy losses attributable to air leakage through the building envelope in conditioned buildings.

Chapter 4 also includes information addressing a number of recognized consensus standards applicable to air retarder testing and evaluation. The standards are referenced in code provisions applicable to roof assemblies and/or may provide some basis for the design of air retarder systems. For these reasons, roof system designers should become familiar with these standards.

Six appendixes round out Condensation and Air Leakage Control: a psychometric chart; U.S. climate zones by state and county as defined by ASHRAE Inc. and referenced in model codes; typical thermal properties of building materials; thermal resistance values for air films and air spaces; radiant barriers; and ASHRAE climatic design information for U.S. locations. A new appendix addressing radiant barriers discusses the working principle, materials, installation and effects on roofing materials.

Reroofing

The volume's reroofing portion benefits significantly from NRCA's Manual Update Committee's work on earlier volumes in the current set, as well as content developed for NRCA building code manuals published during the past two years.

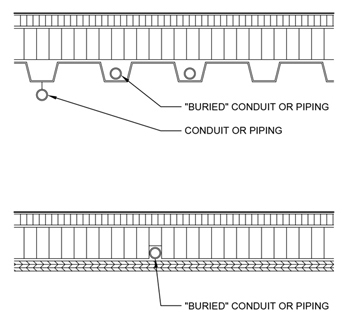

In Chapter 2—Evaluation of Existing Roof Systems, revised discussion of hidden conditions such as electrical wiring and conduit concealed within or just below roof assemblies (see Figure 2) references NFPA 70: National Electrical Code® (NEC) requirements for placement and wiring methods for solar photovoltaic systems. NEC acknowledges the potential for accidentally cutting metallic conduit; however, it does not adequately restrict metallic conduit placement to prevent such accidental cutting during reroofing.

Figure 2: Conduit hidden in or just below a roof assembly

NRCA does not recommend metallic conduit or wiring be embedded within roof assemblies or placed directly below roof decks. If metallic conduit or wiring needs to be placed near a roof assembly, NRCA recommends it be positioned and supported at least 1 1/2 inches from the bottom side of the roof deck or substrate to which the roof system is applied. Also, hangers or other supports used to attach and support metallic conduit and wiring should be attached to framing or roof deck supports, not to the roof deck or roof substrate.

Chapter 3—Building Code Requirements for Reroofing, effectively NRCA commentary to IBC Section 1510—Reroofing, addresses reroofing provisions of the code's 2012 edition.

Content in Chapter 4—Roof Decks for Reroofing essentially covers the same ground as in the 2010 version. In addition to roof deck and substrate types currently used in new construction, Chapter 4 addresses reroofing considerations for precast gypsum and thermal-setting insulating fill, which no longer are used but may be found in reroofing situations. Additionally, a number of revisions introduced in the 2011, 2012 and 2013 volumes were incorporated into updated Chapter 4 text.

Revisions to Chapter 5—Roof Replacement Design Guidelines include expanded information about code requirements for minimum roof assembly fire classification and the addition of discussions of upgrades to insulation and condensation-control components of a replacement roof system.

NRCA's Manual Update Committee decided it no longer was necessary for the reroofing section to address re-covering because chapters in other volumes of The NRCA Roofing Manual separately address re-covering existing roof systems with new roof systems.

A new appendix

When making decisions about roof insulation acceptability, it generally is recognized insulation intended for use in new roof systems and insulation in existing roof systems be evaluated according to different guidelines. A new appendix discusses specific guidelines for moisture content of roof insulation developed by recognized roofing industry experts.

As in the 2010 volume, contact information for organizations referenced in the manual, the standard complement of unit conversion tables and abbreviations, and the glossary are included in the Appendixes.

A full set

The NRCA Roofing Manual: Architectural Metal Flashing, Condensation and Air Leakage Control, and Reroofing—2014 provides NRCA's most up-to-date guidelines applicable to architectural metal flashing, condensation and air leakage control, and reroofing. It complements and is best used with the three earlier volumes of The NRCA Roofing Manual.

Maciek Rupar is an NRCA director of technical services.

COMMENTS

Be the first to comment. Please log in to leave a comment.