In January, North American polyisocyanurate insulation manufacturers implemented updated procedures for testing and reporting the insulation's long-term thermal resistance (LTTR). You should be aware of polyisocyanurate insulation's aging properties and the LTTR methodology, as well as NRCA's opinion regarding whether LTTR accurately predicts polyisocyanurate insulation's long-term R-value.

R-value vs. time

The R-values of closed-cell, polyurethane-type insulation, including polyisocyanurate, are affected by the amount of gas in the foams' cells. Because the R-values of most blowing agents (gases) are greater than that of air, polyisocyanurate insulation's R-value is greatest when there is more blowing agent and less air in the foam's cells.

During polyisocyanurate insulation's service life, air diffuses into the foam's cells and the blowing agent diffuses out of or partially dissolves into the cell's polymer matrix. Each process occurs at a rate dependent on temperature; pressure; and the foam's polymer type, gas type and cell structure. Generally, the inward diffusion of air occurs at a much faster rate than the outward diffusion of the captive blowing agent. Diffusion rates also are affected by the foam's thickness and type of facer sheets.

Because of this phenomenon, polyisocyanurate insulation's R-value is not constant. Its R-value is highest soon after manufacturing and decreases at a relatively significant rate during the earliest portion of its service life. As polyisocyanurate insulation ages further, its R-value decreases at a slower rate until the gas concentration in the foam's cells equals the gas concentration in air, at which point its R-value no longer changes with time.

LTTR

During the early 1990s, Oak Ridge National Laboratory (ORNL), Oak Ridge, Tenn., in cooperation with NRCA, the Polyisocyanurate Insulation Manufacturers Association (PIMA) and SPI: The Plastics Industry Trade Association, conducted research that led to the development of a new methodology for predicting aged R-values for closed-cell plastic foam insulation. This methodology, referred to as LTTR, involves thin slicing and accelerated aging of polyisocyanurate insulation specimens and testing the aged specimens' R-values using ASTM C518, "Standard Test Method for Steady-State Thermal Transmission Properties by Means of the Heat Flow Meter Apparatus."

In 1995, ASTM International published an LTTR test method standard, ASTM C1303, "Standard Test Method for Estimating the Long-Term Change in the Thermal Resistance of Unfaced Rigid Closed-Cell Plastic Foams by Slicing and Scaling Under Controlled Laboratory Conditions," based on this new methodology.

In 1998, the Standards Council of Canada and Underwriters Laboratories of Canada published CAN/ULC-S770, "Standard Test Method for Determination of Long-Term Thermal Resistance of Closed-Cell Thermal Insulation Foams." CAN/ULC-S770 is based on ORNL's research and ASTM C1303 and provides R-value data based on a 15-year time-weighted average, corresponding to a product's R-value five years after manufacturing.

Beginning in 2003, U.S. polyisocyanurate insulation manufacturers began reporting LTTR values using a third-party certification program, referred to as PIMA's QualityMarkcm program. This program used the 2003 edition of CAN/ULC-S770 for LTTR determination.

In 2009, CAN/ULC-S770 was updated; the current edition is CAN/ULC-S770-09. ASTM C1303 also has been updated several times since its original publication; the current edition is ASTM C1303-12.

In June 2013, PIMA announced its QualityMark-certified LTTR program was being updated to incorporate using either CAN/ULC-S770-09 or ASTM C1303-11 for LTTR determination. The updated test methods reportedly result in a more accurate determination and reporting of LTTR values. The new LTTR values are about 4 to 6 percent less than those from 2003 through 2013. The effective date for this change was Jan. 1, 2014.

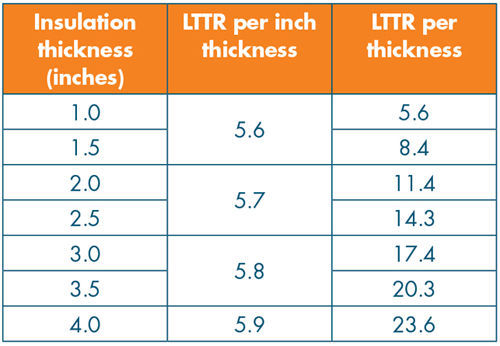

Figure 1: Minimum LTTR values per inch thickness and per thickness prescribed by PIMA's QualtiyMarkcm program

The new minimum LTTR values are shown in Figure 1. The slightly increasing LTTR values per inch thickness are likely the result of the slightly lower cell gas diffusion rates with thicker products.

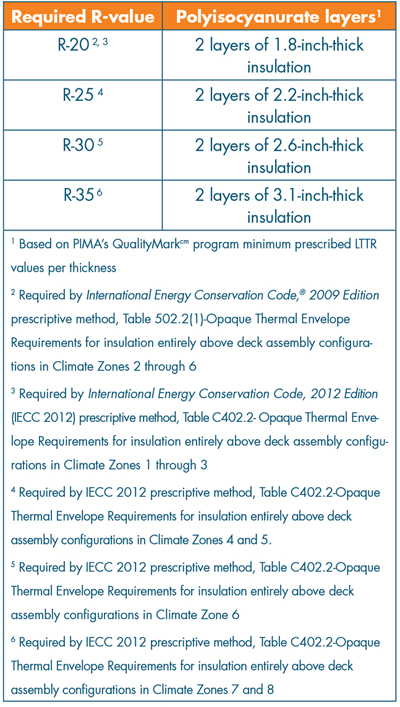

Figure 2: Layers and thicknesses of polyisocyanurate insulation to achieve specified required R-values

The number and thicknesses of polyisocyanurate insulation layers to achieve specific R-values for roof assemblies are provided in Figure 2.

NRCA recommendations

Although NRCA participated in the ORNL research and continues to participate in ASTM International's task group responsible for the LTTR test method, NRCA does not recommend using LTTR for roof system design. The LTTR method for determining and reporting R-values may be appropriate for laboratory analysis and research comparisons; however, NRCA does not consider LTTR to be appropriate for roof system design where actual in-service R-values can be an important aspect of roof system performance.

ASTM C1303 is performed after accelerated aging of test specimens under controlled laboratory conditions, indicated as 72 F ± 10 degrees. Actual rooftop conditions typically vary significantly from these prescribed laboratory conditions.

ASTM C1303 also defines "long term" as five years, which is intended as the time-weighted average of a 15-year period. The implication of this time-weighted average approach is actual R-values may be higher than the LTTR value for an initial five-year period, but R-values also will be less than the LTTR value from years five through 15 and beyond.

The design service lives for most roof systems are longer than the five-year time-weighted average. Twenty-year and longer expected roof system service lives and roof system guarantees now are commonplace. Also, the federal tax code requires depreciating roof assemblies as exterior components of commercial buildings over a 39-year period resulting in a much longer performance expectation. Therefore, NRCA does not view LTTR as being representative of design intentions, actual rooftop conditions or performance expectations.

In 2005, NRCA participated in a limited testing program that showed a majority of polyisocyanurate insulation samples tested one to four years after manufacturing had actual R-values less than their published LTTR values.

In 2009, NRCA conducted R-value testing of polyisocyanurate insulation obtained through distributors; samples ranged in age from four to 13 months. R-values were tested at a 75 F mean reference temperature as well as 25 F, 40 F and 110 F and were found to be less than their published LTTR values.

In 2011, with the publication of The NRCA Roofing Manual: Membrane Roof Systems—2011, NRCA revised its 1987 design R-value recommendations to account for polyisocyanurate insulation's R-values at different temperatures.

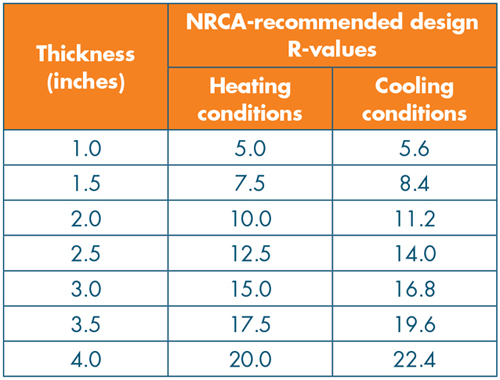

NRCA recommends designers use the design R-values shown in Figure 3 for polyisocyanurate insulation based on the predominant condition for the climate where the specific building being considered is located.

Figure 3: NRCA's recommended design R-values

One way to evaluate whether the heating or cooling condition is predominant is by comparing heating degree day values with cooling degree day values as provided in the ASHRAE Fundamentals Handbook. On this basis, Alabama, southern and western Arizona, southern California, Florida, Georgia, Hawaii, Louisiana, Mississippi, southern Nevada, southern New Mexico, North Carolina, Oklahoma, South Carolina and Texas are considered cooling-predominant. The remaining states are considered heating-predominant.

In 2013, Building Science Corp., Somerville, Mass., published Information Sheet 502, "Understanding the Temperature Dependence of R-values for Polyisocyanurate Roof Insulation," which replicates NRCA's 2009 testing with similar results.

Whether designers use LTTR or NRCA's predominant temperature condition-based design R-values, NRCA recommends designers specify polyisocyanurate insulation by its desired thickness—not its R-value or LTTR—to avoid possible confusion during procurement.

Mark S. Graham is NRCA's associate executive director of technical services.

Thickness tolerances vs. LTTR

The U.S. product standard for polyisocyanurate insulation, ASTM C1289, "Standard Speci?cation for Faced Rigid Cellular Polyisocyanurate Thermal Insulation Board," prescribes allowable dimensional tolerances for polyisocyanurate insulation board products.

A polyisocyanurate insulation board's length and width tolerances shall not exceed ±1/4 inch. A board's thickness tolerance "… shall not exceed 1/8 in. (3.2 mm), and the thickness of any two boards shall not differ more than 1/8 in. (3.2 mm) … ."

Taking polyisocyanurate insulation's thickness tolerance into consideration, the equivalent LTTR of the thickness tolerance is 0.7.

When considering a polyisocyanurate insulation product with an LTTR value reported by the manufacturer to be higher than PIMA's QualityMark-prescribed minimum, it is important to also consider the product's thickness tolerance. In most instances, equivalent LTTR of the thickness tolerance more than offsets any higher reported LTTR value.

For articles related to this topic, see:

Tech Today: "A discrepancy in polyiso's R-values," January 2014 issue

"A measure of performance," August 2013 issue

Tech Today: "R-value concerns," May 2010 issue

Polyisocyanurate R-value testing history

R-values for most insulation products used in the roofing industry are tested using ASTM C518, "Standard Test Method for Steady-State Thermal Transmission Properties by Means of the Heat Flow Meter Apparatus," originally published in 1963. R-values determined using ASTM C158 are representative of the test specimen's R-value at the time of testing.

When urethane foam and, later, polyisocyanurate insulation boards were introduced to the U.S. roofing industry, their R-values typically were reported using ASTM C518 testing conducted immediately after manufacturing and before the cell gas had diffused from the foam's cells and been replaced with air. As a result, R-values of 7.2 or higher per inch thickness were reported for these insulation types.

Beginning in the 1980s, the Roof Insulation Committee of the Thermal Insulation Manufacturers Association's (RIC/TIMA's) conditioning procedure (RIC/TIMA 281-1) and later the Polyisocyanurate Insulation Manufacturers Association's (PIMA's) conditioning procedure (PIMA 101) called for preconditioning foam samples at room temperature conditions (75 F) for 180 days before R-value testing. This preconditioning was an early attempt to address polyisocyanurate insulation's R-value loss over time. Using RIC/TIMA 281-1 or PIMA 101 conditioning, R-values of about 6.6 per inch thickness were reported.

In 1987, based on extensive testing of in-service R-values, NRCA and the Midwest Roofing Contractors Association issued a joint technical bulletin regarding the in-service R-values of polyisocyanurate and polyurethane insulation. The bulletin recommended using an in-service R-value of 5.6 per inch of foam thickness. This in-service R-value was intended to account for polyisocyanurate insulation's R-value losses over time and provides a more realistic design R-value for polyisocyanurate insulation during a roof system's entire design life.

Since 2003, U.S. polyisocyanurate insulation manufacturers have used LTTR for reporting the thermal performance properties of polyisocyanurate insulation.

COMMENTS

Be the first to comment. Please log in to leave a comment.