According to NRCA's 2002-03 market survey, spray polyurethane foam- (SPF-) based roof systems accounted for about $475 million of the $29.69 billion total U.S. roofing industry sales in 2002. Because SPF-based roof systems annually capture a significant dollar volume, it is important for roofing contractors and building owners to procure and use SPF materials that meet minimum building code requirements.

ASTM C1029

SPF currently used in roofing applications does not meet the minimum R-value and dimensional stability requirements of ASTM C1029, "Standard Specification for Spray-Applied Rigid Cellular Polyurethane Thermal Insulation." ASTM C1029 is in the process of being updated, but when changes will be incorporated in a new version of C1029 currently is unknown.

When ASTM C1029 is updated with new requirements for R-value and dimensional stability, SPF that complies with the updated version also will meet minimum building code requirements for five of the six model building codes—BOCA National Building Code, 1999 edition; 1999 Standard Building Code; 2003 International Building Code; 2003 International Residential Code; and Building Construction and Safety Code™ NFPA 5000, 2003 edition.

However, because the Uniform Building Code (UBC) does not explicitly reference ASTM C1029, alternative methods for building code compliance are needed in areas that have adopted UBC. And because of a current lack of model building code compliance, it is necessary roofing professionals who specify and install SPF-based roof systems use alternative methods for code acceptance across the United States.

UBC

In UBC's Section 104.2.8, "Alternate materials, alternate design and methods of construction," language is provided for the acceptance of materials that are not specifically code-approved. An evaluation report can be used to substantiate code acceptance, and the evaluation reports are based on AC12, "Acceptance Criteria for Foam Plastic Insulation."

Some SPF manufacturers have evaluation reports dated before Jan. 1 that previously provided acceptable SPF physical properties. However, a new version of AC12 has been in effect since Jan. 1, and any evaluation report dated before Jan. 1 technically no longer is valid. The Jan. 1 date for the new AC12 coincides with the government-mandated change to blowing agents that do not deplete the ozone layer.

AC12's 2003 version states: "2.4.3 Spray-applied, Rigid Cellular Polyurethane (SPF): These materials, including products into which recycled material is introduced, must comply with the physical property requirements in ASTM C1029-96 as amended in Table 1 of this criteria."

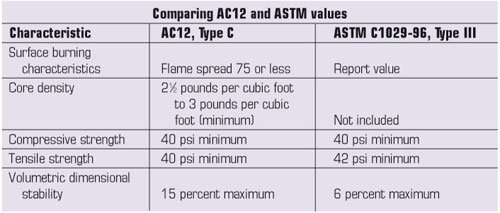

AC12's Table 1 provides specific test criteria for four foam types; Type C foam typically is used in roofing applications. There are five specific tests with appropriate values listed for Type C foams: surface burning characteristics, core density, compressive strength, tensile strength and dimensional stability (see Figure 1).

Figure 1: Comparison of values between AC12 and ASTM C1029-96

NRCA has no concerns with AC12's requirements for surface burning characteristics, core density, compressive strength or tensile strength. However, because a minimum R-value is not listed within Table 1 of AC12, the R-value requirement is as listed in ASTM C1029-96, which is 6.2 for all foam types. Therefore, the R-value requirement for AC12 is a minimum of 6.2; the change to ASTM C1029 would decrease the minimum R-value from 6.2 to 6.0. Although this is a small difference, this possibly is problematic if an SPF's R-value is between 6.0 and 6.2. Apparently, this difference is substantial enough to warrant the SPF industry's proposed change to ASTM C1029.

In addition, dimensional stability is a potential concern. Fifteen percent volumetric dimensional stability can be analyzed as allowing for about 2.5 percent linear dimensional change in three directions. In comparison, the calculated linear dimensional stability limit of 2.5 percent for SPF is larger than all other dimensional stability maximums for other common rigid roof insulation. I believe linear dimensional stability values, not volumetric dimensional stability values, should be determined for SPF for better comparison with other roof insulation and building components.

Compliance issues

For current SPF formulations to comply with building codes, foam must meet ASTM C1029 or AC12. And because current foams do not meet ASTM C1029, no SPF manufacturer is stating compliance with ASTM C1029. Until SPF meets ASTM C1029, the only method to show code compliance is by using evaluation reports.

Simply knowing a manufacturer has an evaluation report is not enough. There is a difference between code approval and code acceptance. Code approval results from a product meeting specific criteria listed in model building codes. Code acceptance means a product is accepted by a code official for use on a case-by-case basis. When a manufacturer provides an evaluation report for SPF acceptance, the installer must provide this information to the code official having jurisdiction. The code official has the right to accept or deny the product's use.

Manufacturers should provide documentation that includes substantiation for code compliance at the time products are purchased. However, this generally does not occur. There are two other ways to determine whether a manufacturer has an evaluation report for a product: searching the Internet or calling individual manufacturers. Because I attempted to track down all outdated and current evaluation reports for SPF-based roof systems, the most efficient method for me was to search evaluation report providers' Web sites.

To accomplish the Internet search, I used a list of spray polyurethane foam suppliers from the Spray Polyurethane Foam Alliance's Web site, www.sprayfoam.org, which likely is the most up-to-date and complete list of SPF suppliers.

The two main evaluation service providers are the International Conference of Building Officials (ICBO) and Southern Building Code Congress International (SBBCI) Inc.'s Public Safety Testing & Evaluation Services Inc.

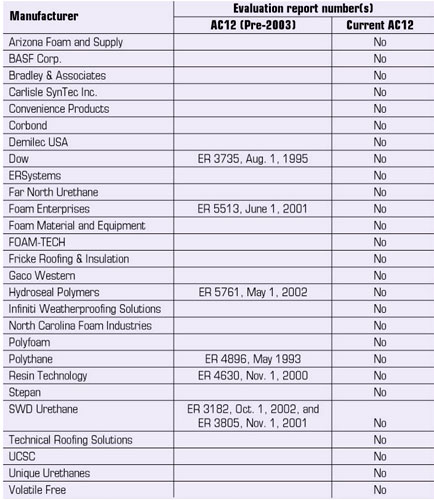

At press time, of all the evaluation reports that are SPF-based roof system-specific listed on ICBO's Web site, www.icbo.org, none are for the newest version of AC12 (see Figure 2).

Figure 2: A list of evaluation reports that are SPF-based roof system-specific

A search on SBCCI's Web page www.sbccies.org/Evaluation/reports.htm#98 resulted with zero reports for coated SPF-based roof systems according to the 2003 version of AC12. A listing for gravel-surfaced foam was found, but the scope of that evaluation report is limited to fire and wind resistance, not material compliance to a specific standard.

Be proactive

If you are involved with installing SPF-based roof systems, I encourage you to become familiar with the specific requirements for building code compliance. SPF manufacturers should provide adequate and appropriate code compliance information. Installers and specifiers of SPF should request SPF manufacturers provide specific substantiation for building code acceptance or written verification for each job that the installed foam meets code approval.

James R. Kirby is an NRCA senior director of technical services.

For more information related to this story, refer to the following Professional Roofing articles:

For additional information about spray polyurethane foam, search Professional Roofing's Web site using the search function.

COMMENTS

Be the first to comment. Please log in to leave a comment.