During the past several months, NRCA's Technical Services Section has received a number of inquiries from contractors who have noted some variability in the thicknesses of rigid board insulation products. In this month's column, I explore the thickness tolerances commonly associated with rigid board insulation products, explain a concern that may result in the field because of such allowable tolerances and offer a suggestion for addressing the potential problem.

Allowable tolerances

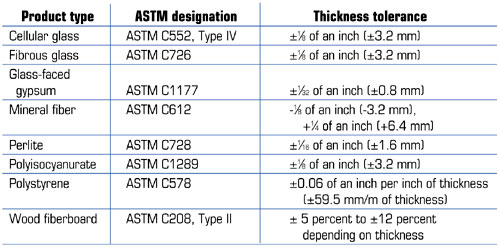

ASTM International's product standards for rigid board insulation products typically contain dimensional tolerances governing variability in products' allowable lengths, widths and thicknesses. These dimensional tolerances vary based on specific product types. The figure shows ASTM's allowable thickness tolerances for rigid board insulation products commonly used in roof systems.

For example, for polyisocyanurate insulation, ASTM C1289, "Standard Specification for Faced Rigid Cellular Polyisocyanurate Thermal Insulation," provides for an allowable tolerance of ±1/8 of an inch (±3.2 mm) from the product's nominal thickness. Therefore, a polyisocyanurate insulation board with a nominal thickness of 1 1/2 inches (38 mm) is allowed to range in average thickness from 1 3/8 inches (35 mm) to 1 5/8 inches (41 mm) and still comply with ASTM C1289.

Allowable thickness dimensional tolerances for rigid board insulation products used in roofing

For wood fiberboard insulation, ASTM's allowable tolerance is expressed as a percentage of product thickness, which varies based on product thickness. For example, 1/2-inch- (13-mm-) thick wood fiberboard is allowed a tolerance of ±10 percent of product thickness, which is ±0.05 of an inch (±1.3 mm). A 3-inch- (76-mm-) thick wood fiberboard is allowed a tolerance of ±5 percent, which is ±0.15 of an inch (±3.8 mm).

Concern

A potential problem in the field exists where the actual thickness of rigid board insulation is at an allowable extreme of its thickness tolerance and the work interfaces with adjacent construction where thickness is critical.

For example, consider a roof edge gutter detail where 3 inches (76 mm) of wood blocking is installed to accommodate the thickness of two layers of 1 1/2-inch (38-mm) nominal thickness polyisocyanurate insulation. Because the thickness tolerance for polyisocyanurate insulation allows each insulation layer to be a minimum of 1 3/8 inches (35 mm) thick, the total thickness of the two layers could be as little as 2 3/4 inches (70 mm). This particular scenario would result in a 1/4-inch (6.4-mm) offset in the finished top surface at the interface between the insulation and wood blocking. Considering this offset and the additional thickness of the gutter flange and membrane stripping plies over the gutter flange, this condition likely would result in ponding water on the completed roof surface along the gutter edge detail.

A suggestion

A possible solution to the described problem is for roof system designers, manufacturers and contractors to specify more restrictive allowable thickness tolerances for rigid board insulation used in situations where actual thickness is critical in properly interfacing with adjacent construction, such as flat edge details and gutters. ASTM's product standards for rigid board cellular glass, polyisocyanurate and polystyrene insulation contain specific provisions allowing for such modifications to dimensional tolerances provided there is agreement between the seller and buyer of the product.

Additional information regarding dimensional tolerances for rigid board insulation products is available in ASTM standards and from roofing material manufacturers.

Mark S. Graham is NRCA's associate executive director of technical services.

COMMENTS

Be the first to comment. Please log in to leave a comment.