For years, the roof tile industry has been asked to develop an industry-based installation manual that would provide recommendations for installing concrete and clay roof tile in moderate climate regions of North America.

During the past two years, members of the Roof Tile Institute (RTI) (formerly the National Tile Roofing Manufacturers Association) have worked with the Western States Roofing Contractors Association (WSRCA) to assemble such a manual, which provides best installation practices, industry standards and available code requirements.

The new manual, Concrete and Clay Roof Tile Installation Manual for Moderate Climate Regions, was released to the design/build community in June 2001. The changes made to the manual became effective in the field Jan. 1. The new manual can replace the numerous individual installation guides currently in circulation, which are provided by individual tile manufacturers as part of their code approval. There currently are more than 50 manuals by various tile manufacturers in North America. Almost all tile manufacturers in North America now have formally replaced their manuals with RTI's and WSRCA's manual.

The 73-page manual contains detailed recommendations and drawings that address every aspect of roof systems used with tile products. The recommendations are meant for areas with moderate climates that may experience occasional winter storms and heavy rain. In locations where the January mean temperature is 30 F (-1 C) or less or where ice damming occurs, RTI and WSRCA suggest roofing professionals refer to the organizations' Concrete and Clay Tile Roof Design Criteria Manual for Cold and Snow Regions. (Copies may be ordered on RTI's Web site, www.rooftile.org.)

Design

Although the manual's recommendations generally are considered minimum standards, proper adherence to the recommendations and attention to detail and workmanship should provide functional roof systems in all but the most severe conditions. Local building officials should be consulted for engineering criteria or other special requirements.

The manner in which tile roof systems are installed makes them highly effective at water shedding and affords years of service and protection. The effectiveness of a tile roof system as a weather-resistant assembly, however, depends on the proper installation of the tile roof components.

Because tile is installed in a wide range of climatic conditions and geographic areas, a variety of details must be considered when preparing for an effective installation. The minimum recommendations for moderate regions in the manual are effective for a range of conditions, including occasional heavy rain or snow. Although it is not practical to prescribe precise solutions for all conditions, the manual has been designed to offer suggestions for various treatments in moderate climate applications. Local building officials always should be consulted about special requirements that may exist.

Some changes from previously accepted procedures included in this manual represent an upgrade in the minimum requirements for tile installation and will require code approval from the International Conference of Building Officials (ICBO). The manual has been submitted to ICBO's evaluation service (ICBO-ES) to obtain a report number.

Minimum design recommendations with optional upgrades for the installation of underlayment, flashing and fastening and related measures to provide weather-resistant roof assemblies for concrete and clay tile are provided in the manual. RTI and WSRCA stress roof system designers should be familiar with local climatic conditions and review the proper design manual.

The tile manual has been designed to be the foundation of the installation guides RTI offers. In the manual, RTI and WSRCA attempt to provide basic, general information about tile that includes information about material checklists, tile specifications and recommendations, materials and manufacturing; definitions of terms relating to tile; high-wind considerations; and general topics about tile issues.

When combined with the supplemental manual for cold-weather applications as previously referenced and FRSA/RTI—3rd edition South Florida Installation Manual, the manual will provide a complete library of tile references.

Clarifications

The manual does not significantly change the way clay and concrete tile are installed but rather tries to clarify the most common methods of application and create a single document for industry reference.

In fact, there only are four major areas that have been highlighted for roofing professionals to notice. These areas include the following:

1. Recommendation for a minimum requirement of No. 26-gauge (G90) metals for flashing. With the new International Code Council (ICC) codes about to take effect, RTI and WSRCA have updated flashing requirements to include the use of No. 26-gauge metal.

This will include valleys, wall trays (pans), roof-to-wall flashings and pipe flashings. (Pipe flashings for profile tile can be 21/2-pound [1.1-kg] lead or dead-soft aluminum with an 18-inch- [4.6-mm-] wide skirt.) Wall counterflashing also will be No. 26-gauge, galvanized Z-bar flashing or surface-mount reglet (pin) flashing for reroofing projects.

2. Recommendation for the use of ASTM D226 Type II (No. 30 felt) as a minimum underlayment. This recommendation is not a new concept and has been in practice for the past few years. For new construction, this will mean: One layer of ASTM D226 Type II (No. 30 felt), in a recognized code evaluation report, completely will cover the deck and be lapped over the hips and ridges and through valleys. Underlayment will be lapped 6 inches (1.5 mm) vertically (end or side lap) and 2 inches (0.5 mm) horizontally (head lap). On roof slopes from 2 1/2-in-12 (12 degrees) to less than 3-in-12 (14 degrees), an approved built-up roof system applied in accordance with Figures 1 and 2, a single-ply roof membrane assembly or other underlayment system approved by a local building official first is installed. Tile roofs with slopes less than 3-in-12 (14 degrees) still are considered decorative. For roofs with slopes between 3-in-12 (14 degrees) and 4-in-12 (18 degrees), underlayment may be installed as described previously or a single layer of Type 90 granular-surfaced asphalt roll roofing; two layers of ASTM D226 Type II (No. 30 felt) installed in shingle fashion; single-ply system installed per code; or other approved underlayments may be installed.

3. The fasteners for tile securement must meet ASTM A641 Class 1 or equal approval. After Hurricane Andrew struck south Florida, RTI spent several years attempting to identify a specific ASTM standard that could be referenced for use within the manual. Previously, there had not been a proper way to identify a specific coating level. The ASTM A641 Class 1 specification provides a minimum weight of zinc per unit area of uncoated wire surface. Because the nail industry never has been able to equate surface coating to expected life of a fastener, RTI has determined that by specifying the minimum adherence to ASTM A641 Class 1, RTI and WSRCA will at least form a threshold for tile fasteners to meet. The balance of the fastener requirements will come from the Uniform Building Code (UBC).

4. The manual states: "Openings at hips, ridges and head walls shall be fitted with weather-blocking material to keep water on the surface of the field tile. Other methods approved by the local building official will be allowed." This statement appears as a note on pages 49 and 50 of the manual. Although performed in most U.S. regions, there are specific areas in the Southwest where this practice has not been used. RTI was concerned enough about this issue to provide a subsequent Technical Bulletin about weather-blocking issues; it can be downloaded at www.rooftile.org. The bulletin provides the numerous options that are available for roofing professionals to consider. The issue of ICBO-ES-approved weather-blocking materials still is being developed. There currently is not an approved acceptance criteria against which weather-blocking materials are tested. Discussions with ICBO-ES and several weather-blocking manufacturers are occurring to commence drafting acceptance criteria. Once completed, the products then can be tested against those criteria for an official ICBO-ES approval as a weather-blocking material.

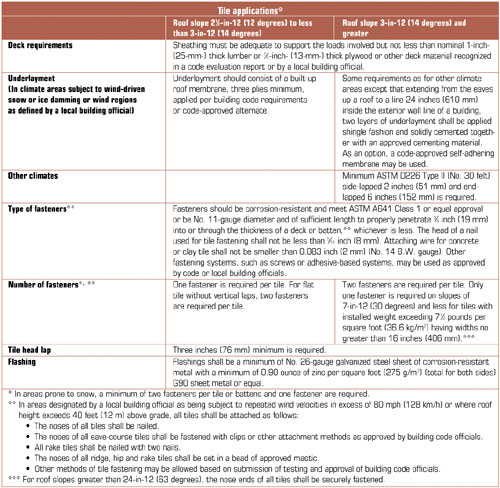

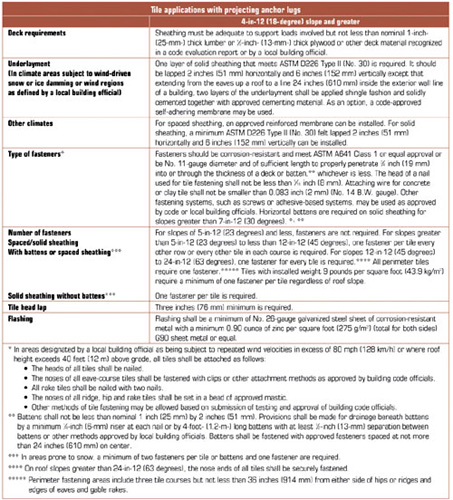

A majority of installation requirements can be found in Figures 1 and 2, which provide the information many roofing professionals have learned from the UBC tables 15D-1 and 15D-2. For most U.S. regions, Figure 2 should be referenced because most tiles have projecting anchor lugs.

Figure 1: Roofing tile applications for all tiles not listed in Figure 2

Figure 2: Roofing tile applications for concrete and clay tiles with projecting anchor lugs when installed on roof slopes of 4-in-12 (18 degrees) and greater

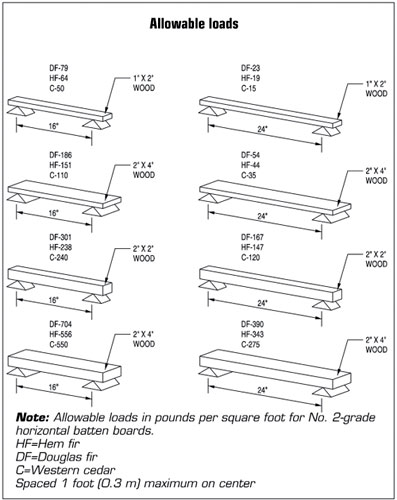

In Figure 3, RTI and WSRCA have provided batten and counterbatten allowable loads according to species and dimensions. The figure was based on engineering calculations and is provided as a guideline for design professionals.

Figure courtesy of the Roof Tile Institute

Figure 3: Batten and counterbatten allowable loads according to species and dimensions

Drawings

The manual also includes isometric AutoCAD drawings that will be uploaded to RTI's Web site by the end of 2002. As a natural progression of the roofing process, users will be able to view RTI and WSRCA recommendations for sheathing, underlayment, batten placement, roof loading, fascia treatment, headwalls, chimney/sidewall, skylights, valleys, hips and ridges, rakes, gable/eave installations, dormers, slope changes and specialty pre-engineered roof conditions.

The manual also includes sections about underlayments for spaced sheathing application and adhesive fastening systems as an alternative to mechanical fastening.

High-wind applications

The installation of tile in high-wind areas primarily has been the focus of the Florida Roofing, Sheet Metal and Air Conditioning Contractors Association (FRSA)/RTI manual for south Florida, but there are other specific areas in the United States that are recognized by ASCE-7-98 wind maps as having winds above 80 mph (128 km/h).

Because RTI provided all the Redland wind-tunnel research for concrete and clay tile in the early 1990s to Southern Building Code Congress International Inc., south Florida and ICC for the development of recognized uplift resistance for tile, RTI and WSRCA included a section for design considerations in the manual.

RTI and FRSA derived various uplift-resistance values for nails, screws and adhesive fastening systems that can withstand installations up to 140 mph (224 km/h). Each installation method may have limiting factors depending on wind speed.

Earthquake zones

Another concern from consumers in certain U.S. regions is earthquakes. As a result, RTI and the University of Southern California's Structural Engineering Department conducted a series of tests on seismic performance of concrete and clay tile.

The tests concluded that tile, when installed according to current UBC requirements, withstood forces almost twice the code requirements for structures. Tile is the only roofing material that has undergone such testing and resulted in a finding that no additional fasteners are required.

Quality

RTI and WSRCA ask specifiers, designers, builders and roofing professionals to review the new manual and become familiar with the recommendations provided. By raising the quality of tile installations, RTI and WSRCA believe longer-lasting roof assemblies will be installed.

Based on the input received from ICBO-ES, there will be a revised edition of the manual available this spring. (At press time, the revised edition was not available.) The revised edition will incorporate the new nonpermissive code language required. In addition, RTI and WSRCA will provide a Spanish-language version of the manual by the end of 2002.

As a follow-up to the manual, RTI and WSRCA will be developing a brief training presentation that should be available on RTI's Web site later this year. The presentation will provide a page-by-page tutorial of the changes that have been included in the manual, as well as any revisions.

Copies of the manual are available from RTI's member companies or WSRCA. Comments or input about the manual are encouraged and welcomed. E-mail them to me at Rolson@rooftile.org, or call (541) 689-0366.

Richard K. Olson is president of RTI.

COMMENTS

Be the first to comment. Please log in to leave a comment.