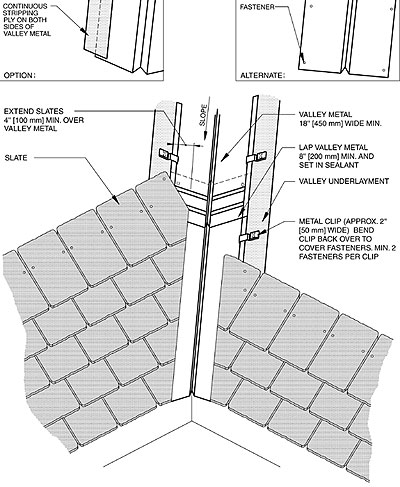

The most common type of valley construction used with a slate roof system is an open valley lined with sheet metal (see figure). Open valleys permit clear, unobstructed drainage and are advantageous in locations where debris from surrounding foliage settles on a roof's surface and accumulates in valleys and around penetrations.

Detail Slate-6 from The NRCA Roofing and Waterproofing Manual, Fifth Edition.

NRCA suggests the metal used in an open-valley slate roof system have a gauge or weight that reflects the anticipated service life of the slate roof system. The valley should be fabricated from one of the metal types listed in The NRCA Roofing and Waterproofing Manual, Fifth Edition.

In climates prone to accumulations of snow and ice or with regular freeze-thaw cycling, open-valley construction should be enhanced. The valley area can be lined with a self-adhering polymer-modified bitumen underlayment material before installation of the valley metal. In addition, the flanges on either side of the valley metal can be stripped in with 9-inch- to 12-inch- (229-mm- to 305-mm-) wide strips of self-adhering polymer-modified bitumen underlayment material. The self-adhering strips are bonded onto the valley metal flange and self-adhering underlayment material.

Once the underlayment is installed, the valley metal should be installed in lengths not to exceed 10 feet (3 m) and be a minimum 18 inches (457 mm) wide. The metal can be formed in either a "V" shape or "W" profile formed along the center line. The "W" profile offers more rigidity and helps keep water from running under the valley slate.

The field of the slate roof can be laid out once the valley metal has been installed. The slate should be laid out so the first piece of slate is spaced 4 inches (102 mm) from the center line of the valley and positioned a minimum of 4 inches (102 mm) over the valley metal. The layout should be calculated to avoid installing small pieces of slate (less than 2 inches [51 mm] at the butt end) in the metal valley area.

Cut pieces of slate in the valley area generally require new holes be punched to avoid fastening the slate through the metal valley. If it is necessary to use smaller pieces of slate in the valley area, NRCA recommends a wire-tie system to avoid fastening through the valley metal. Slate installers often will set wired slates in a dab or bed of appropriate roof cement to prevent the slates from shifting.

Chuck Scislo is an NRCA senior director of technical services.

COMMENTS

Be the first to comment. Please log in to leave a comment.