Spray polyurethane foam- (SPF-) based roof systems are constructed by mixing and spraying a two-component liquid that forms the base of an adhered roof system. The mixture expands 20 times to 30 times its liquid volume and forms a closed-cell foam insulation. An elastomeric coating usually is applied to the foam insulation and provides the long-term weatherproofing characteristics of SPF-based roof systems.

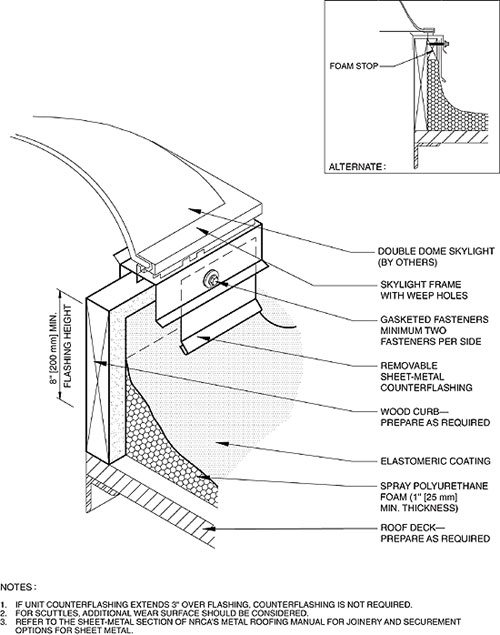

Polyurethane foam flashings with elastomeric coatings, as depicted in the detail, are sprayed in place and become an integral component of an SPF-based roof system. SPF forms a monolithic, continuous, self-adhered flashing detail. At skylight penetrations, SPF is applied to form a fillet or cant at the base of a skylight curb and then is applied up the vertical surface to a desired flashing height. A polyurethane foam flashing detail requires an elastomeric coating up the curb and above the termination line of the SPF.

At skylight curbs, the SPF should terminate a minimum of 6 inches (152 mm) above the horizontal SPF roof surface with the elastomeric coating extended a minimum of 2 inches (51 mm) above the SPF.

Detail SPF-14 from The NRCA Roofing and Waterproofing Manual, Fifth Edition.

In some cases, if the skylight dome frame has a vertical leg or flange that extends at least 3 inches (76 mm) down the curb, the removeable sheet-metal counterflashing may not be necessary.

All substrate surfaces should be prepared to ensure proper foam and elastomeric coating adhesion. Surface preparation, such as cleaning, etching and priming, may be required before SPF application.

The skylight depicted in the construction detail is double-glazed and rests on a field-constructed wood curb. As expected, there are additional configurations besides the representation in the manual. Skylight units can be single-, double- or triple-glazed. In addition, lenses are available in different materials, the most common being glass, acrylic or polycarbonate. The detail also shows a curb constructed from wood blocking. Many skylights have integral curbs, and the curbs often are insulated and sealed for improved thermal performance.

Joan P. Crowe is an NRCA manager of technical services.

COMMENTS

Be the first to comment. Please log in to leave a comment.