Editor's note: The following information reflects the author's opinions and not necessarily those of NRCA.

The next time you nail down a high-performance shingle or roll out polymer-modified bitumen, you may be helping to keep waste plastics out of landfills, oceans and the environment.

New synthetic additives can reduce a roofing manufacturer's formulation cost while improving the physical characteristics of roofing asphalt, likely resulting in next-generation shingle or roll products with greater resistance to climatic extremes and mechanical stress.

My company, GreenMantra Technologies,® Brantford, Ontario, converts waste plastics into specialty additives designed for use in asphalt, plastics, rubber and adhesive formulations. The company's products are made with 100 percent recycled plastics that are transformed through a patented process into various types of polymer additives for asphalt roofing and other end uses.

Each pound of waste plastic feedstock yields 0.95 pounds of specialty additive. So for every ton of product used in a roofing formulation, 1.05 tons of plastic are diverted from landfills.

Improving performance

These new polymer additives can enhance roofing asphalt performance and durability while lowering production costs. When combined with either unmodified or polymer-modified asphalt, the products, marketed under the Ceranovus™ name, can improve the application and performance characteristics of asphalt intended for use in rolled roof sheets and shingles.

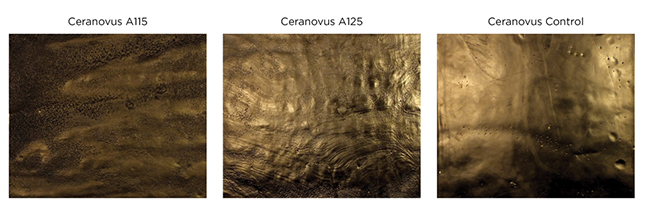

Dimensional heat stability at 176 F of rolled asphalt sheets made with and without additives and aged for 24 hours |

Not only are these additives environmentally beneficial, they also can provide significant physical performance advantages when used in next-generation roofing products.

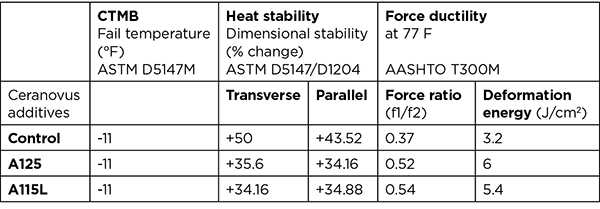

The primary performance challenges for roofing are temperature extremes and mechanical stress. All the data I present are the product of extensive third-party testing and evaluation by PRI, Tampa, Fla. The findings show that in polymer-modified bitumen sheets, the new additives can improve a number of performance parameters. Results of testing for dimensional heat stability (rolled asphalt sheets aged at 176 F for 24 hours) and force ductility (amount of force required before deformation) are shown in Figure 1.

Figure 1: How additives affect SBS polymer-modified bitumen properties. Note the improvement in dimensional heat stability and force ductility while low-temperature flexibility test values remain unchanged. |

When compared with the control—a generic coating formulation for commercial polymer-modified membranes supplied by PRI—asphalt formulations modified with the additives hold their shape better with less sagging when subjected to elevated temperatures (see photos) and are more resilient. In practice, these improvements should add up to decreased warping during storage, transport and use of roofing materials. In addition, higher force ductility values suggest roofing materials made with these products should offer greater resistance to hail and other impacts. Finally, as shown by low-temperature mandrel bend testing (low-temperature flexibility testing) the additives did not change the coatings' low-temperature performance—their brittleness did not increase. This is important because many additives that might improve asphalt's stability or strength at warmer temperatures will cause it to fracture more readily at colder temperatures. These products do not.

Figure 2: The effects additives have on softening point and penetration in SBS polymer-modified bitumen |

In another round of testing, the additives were shown to increase the coatings' softening point. Softening at higher temperatures means less sagging and deformation at higher temperatures—and decreased penetration from mechanical stresses. This improvement is important because of the amount of foot traffic on roof systems (see Figure 2).

Raising the softening temperature of the coating component in asphalt-based roofing materials and making it stiffer through modification with specialty additives is expected to raise roofing materials' performance and durability.

Energy and cost savings

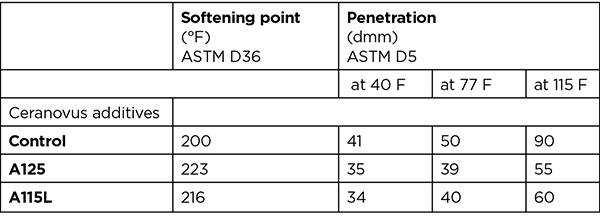

In addition to mechanical performance benefits, the additives can help with processing during manufacturing. For example, they lower asphalt's viscosity (see Figure 3).

Figure 3: Viscosity in relation to temperature of control asphalt and asphalt modified with a 2 percent additive formulation |

Lowering an asphalt formulation's viscosity at process temperatures reduces the time needed for the asphalt to saturate the fiberglass matting, leading to faster production and lower energy consumption per unit produced. In SBS or APP polymer-modified bitumen, the additives hasten polymer dispersion, reduce mixing times and produce smoother asphalt coatings on fiberglass matting. The smoother asphalt coating translates to fewer failures during the life of the shingle or roll.

Better adhesion

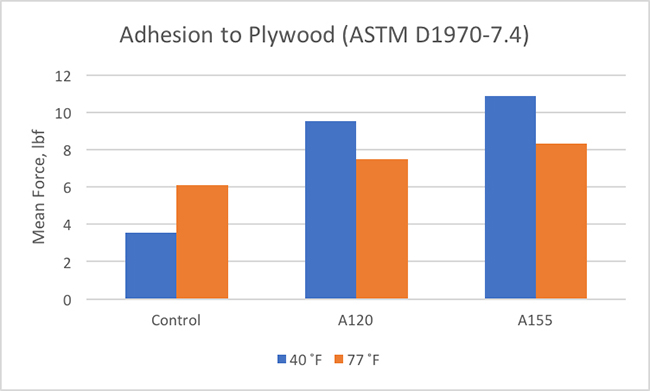

In addition, the additives also have been shown to improve adhesion. In one application—a self-adhering waterproofing underlayment formulation provided by PRI—substituting about 30 percent of the SBS in the polymer-modified bitumen formulation with a polymer additive resulted in two- to three-fold improvement in adhesion, especially at low temperatures (see Figure 4).

Figure 4: Adhesion performance at low and high temperatures: control (PRI-formulated typical peel-and-stick adhesive, including base asphalt, asphalt extender, SBS, a sulfur cross-linker and dolomite filler) vs. control modified with additive formulations |

All these technical advantages—enhanced high-temperature stability, significantly improved product strength (force ductility/deformation), better adhesion, lower viscosity and consistent low-temperature behavior—can translate to higher performance in the challenging roof environment with cost-saving benefits. And because the materials are produced from 100 percent recycled materials and contribute to the recycled content of finished roofing products, they also may enhance eligibility for LEED credits, an important consideration in many modern building projects.

Reusing plastics

Plastic waste—and what to do with it—is a pressing global problem. Of the more than 300 million pounds of plastic produced each year, only about 10 percent is recycled, according to U.S. and Canadian government estimates. Much of the remaining material is sent to landfills, incinerated or discarded into the environment after a single use.

Alarmingly, an estimated 8 million tons of plastic waste enters the oceans each year, according to a recent World Economic Forum (WEF) report. WEF estimates that at current disposal rates, by 2050 plastic will outweigh marine life in the ocean with devastating effects.

GreenMantra Technologies is one of a number of companies striving to create a circular economy for plastic in which it is recycled, remade into high-value products for roofing and other applications, and beneficially reused.

GreenMantra Technologies' technology enables the company to use even hard-to-recycle waste plastic materials such as grocery bags and agricultural film as feedstock. According to the Canadian Plastics Industry Association and American Chemistry Council, polystyrene is one of the world's fastest-growing waste plastics with low associated recycling rates. A new technology the company has developed enables the conversion of polystyrene into useful specialty polymers. GreenMantra Technologies is studying ways to use these modified styrenic polymers in various end-use applications.

Capturing the hidden value in waste polymers is at the core of GreenMantra Technologies' strategy. The company believes it makes sense to ensure those materials are beneficially reused rather than discarded after a single use.

GreenMantra Technologies' process of converting waste plastics into synthetic polymers also reduces reliance on traditional feedstocks such as oil, coal and natural gas, which can conserve fossil fuels and reduce greenhouse gases.

And the company's product portfolio is helping to disprove the long-standing perception that cost and performance are sacrificed for environmentally responsible products. Rather, improved performance and cost savings are possible when using materials produced through the circular economy.

GreenMantra Technologies currently is diverting more than 5,000 metric tons of waste plastics annually for use in various synthetic additive products. The company has announced plans to expand its capacity 50 percent in the short term. It also has announced plans to build a new plant to begin upcycling and converting polystyrene into specialty styrenic polymers.

Considering the future

I envision a future in which a significant portion of waste plastics is upcycled and reused, and I believe GreenMantra Technologies will play a significant part in this change.

Demand for additives that add value to end products is ongoing. GreenMantra Technologies is just scratching the surface of how it can reuse waste plastics to create enhanced materials for customers in a wide range of markets, including the roofing industry.

Domenic Di Mondo is senior director, research & business development, for Brantford, Ontario-based GreenMantra Technologies.®

COMMENTS

Be the first to comment. Please log in to leave a comment.