Low-rise polyurethane foam insulation adhesives have become increasingly popular since their introduction into the roofing industry about 30 years ago. They can perform well and offer a number of advantages over mechanical roofing fasteners.

Designers may prefer low-rise foam adhesives to other securement types for certain applications—for example, with new roof system construction and reroofing over non-nailable decks, such as pre-cast or poured-in-place concrete; where mechanical fasteners may compromise a roof deck's structural strength, such as reroofing applications over cementitious wood fiber decks; where job-site restrictions rule out the use of asphalt adhesives; or where a design objective is to avoid penetrations or thermal bridging associated with metal fasteners.

Also, when designing for extreme wind loads, low-rise foam adhesives can provide wind uplift-resistance levels not available with other adhesives or impractical with mechanical fasteners.

On the other hand, low-rise foam adhesives present many more opportunities for performance problems than other roof system attachment methods mainly because low-rise foam adhesives are sensitive to job-site and environmental conditions and unforgiving of deviation from manufacturers' application recommendations. Your understanding of the considerations associated with low-rise foam adhesives can be critical to roof system performance.

Formulations

There are two low-rise foam adhesive formulations: one-component and two-component polyurethane adhesives. One-component adhesives commonly are referred to as "moisture-cured" adhesives because their curing reaction relies on ambient moisture. Two-component adhesives are "chemically cured." Two-component adhesive products' separately packaged parts contain all the necessary reactants and require careful mixing of components at the application point to obtain desired adhesive strength. According to manufacturers, shelf life for both formulations ranges from six to 18 months depending on the product.

Both formulations generate byproducts of heat and carbon dioxide during curing. The released heat helps drive the curing reactions to completion and vaporizes blowing agents added to some low-rise foam adhesive products, which intensifies the foaming action intended to help fill gaps between bonded surfaces and increase adhesive contact area. Surfactant additives prevent foam from collapsing and developing voids.

One-component formulations typically take longer to foam and have "lower rise" (expand less) than two-component formulations. The latter expand to cover a relatively larger surface area and cure more rapidly.

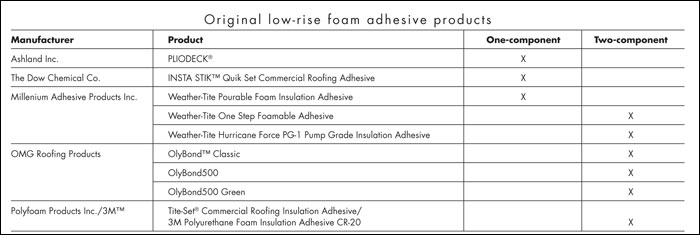

Original suppliers of low-rise foam adhesives and their product offerings

Recently, it has become common for roof system manufacturers to privately label low-rise adhesive products from established suppliers. Although this practice may have helped increase end users' awareness of low-rise foam adhesives and raise confidence in the adhesives' compatibility with many roof system components, it also created the false impression that many new and different product choices were being introduced to the market.

Distinct low-rise foam adhesive formulation choices are actually fewer than marketing literature suggests. The figure shows original suppliers of low-rise foam adhesives and their product offerings.

One-component products

One-component polyurethane adhesives are in large part composed of partially reacted precursor polymer chains terminated by unreacted isocyanate groups and smaller isocyanate-bearing compound molecules called chain extenders or cross-linkers. Effectively, such adhesives' composition is a carefully blended off-ratio mixture formulated to allow application in a fluid state.

Once unsealed for use, a one-component adhesive contacts water from the air, which reacts with the excess isocyanate groups to form permanent cross-links. An adhesive is completely cured when enough water vapor has diffused through it to react with all available isocyanate groups.

Achieving sufficient cure levels to secure insulation boards in place and allow for roofing over them in dry air and low temperatures may take a relatively long time—up to an hour or more. This is why application of one-component polyurethane adhesives may be difficult or impractical in cold weather and when the air above a substrate holds little moisture. Some products' cold weather application guidelines call for spray application of accelerant solutions over freshly applied adhesive.

One-component adhesive products packaged in sealed pails and containers are stored and shipped with their lids facing down to prevent air exchange, which could affect the products' shelf life. Adhesive is poured directly from its container or a gravity-feed applicator onto a substrate in a continuous bead or beads typically spaced 12 inches on center. Wheeled applicators are designed to produce uniform bead spacing in rows of four or more. Application rate primarily is controlled by an operator's walking speed.

Pressurized tank packaging also is available with some one-component products. A bead can be sprayed onto a substrate from an operator-portable tank, or several beads can be dispensed from a wheeled applicator designed to hold multiple tanks.

Two-component products

Two-component polyurethane adhesives begin to cure after their diisocyanate (part A) and resin (part B) components are mixed. Such products' packaging and mixing equipment are designed to promote intimate component mixing at a specific volumetric ratio required to react all active groups. Application equipment operation and maintenance instructions essentially are directions for keeping the components flowing at a fixed ratio.

Parts A and B may be individually sealed inside a cartridge made up of two cylindrical compartments designed for use in hand-held applicators. These operate similar to a caulk gun and use hand-, air- or DC motor-actuated pistons to force both components out of their compartments and through a mixing tip. Products packaged this way typically are used for small jobs or in confined areas. Each cartridge holds enough adhesive for 1 to 1 1/2 squares of roof surface coverage.

Cartridges also can be mounted in groups of four or more on wheeled equipment to simultaneously place multiple beads of adhesive at a preset spacing.

Parts A and B also are available packaged separately in 5-gallon and larger containers, which provide enough adhesive for 10 squares of coverage or more depending on packaging size and bonded surface types. These larger containers may be pressurized or designed for use with mixing carts equipped with gravity-fed pumps. The two components are forced through separate supply hoses to a hand-operated dispenser assembly and through a disposable mixing tip. Products intended for complete substrate coverage may be applied using traditional insulating spray polyurethane foam application equipment.

With some two-component polyurethane products, there are different grades available for cold and warm weather applications. A winter formulation may contain higher concentrations of reactive groups or catalysts to promote more rapid curing. This offsets the reaction rate penalty from low temperatures.

Substrates

In a roof assembly, a low-rise foam adhesive produces the highest uplift resistance when it contacts dry, flat, porous surfaces free of dust, debris and film. The adhesive fills voids in each surface's texture and, upon curing, provides mechanical interlocks at each interface. Standing water and surface contamination interfere with this mechanism as does a material's low cohesive strength at the interface.

Flatness of substrates and board stock is especially important before adhesive develops cured strength—flatness helps maintain consistent adhesive contact throughout the application area. Bond strengths increase with increasingly rigid materials because reduced material deflection under load translates to less strain on the adhesive and less fatigue over time.

Low-rise foam adhesives have been used successfully for adhering board stock to various substrate types. Compatible roof decks include poured and pre-cast structural concrete, insulating concrete, gypsum, cementitious wood fiber, steel and wood panels. Best practice recommendations have been developed to address material-specific adhesion issues.

For example, concrete decks should be allowed sufficient cure time to remove residual moisture before applying low-rise foam adhesives because moisture can weaken organic fiber facers used with popular rigid board insulation products. Recommendations for application over steel call for minimum 22-gauge steel deck panels and painting and priming to improve adhesive bond strength.

For insulation attachment over steel decks using low-rise foam adhesives, NRCA continues to recommend a flat substrate of rigid board be mechanically fastened to the deck before dispensing adhesive.

Other substrates appropriate for use with low-rise foam adhesives include vapor retarders, base sheets, re-cover boards and rigid board insulation. Adhesive manufacturers provide listings of compatible products from these categories.

Some examples of substrates that may be incompatible with low-rise foam adhesives or require additional surface preparation before applying such adhesives are aggregate-surfaced built-up roof systems, weathered asphalt, foil-faced insulation and base sheet products not yet tested for compatibility. In some cases, a manufacturer may require satisfactory completion of field uplift pull tests as a condition of substrate approval.

Substrate compatibility with low-rise foam adhesives sometimes is not as clear for re-cover applications as it is for new construction or decks exposed for reroofing. An evaluation with the adhesive manufacturer may be necessary to determine the correct steps for surface preparation.

Typical manufacturer recommendations include removing contaminants and loose material by sweeping, vacuuming or power washing and applying a primer. Alternatively, a mechanically attached re-cover board may be recommended when penetrating the existing roof is acceptable.

Adhered roofing components

Types of rigid board insulation and cover boards that can be attached to roof decks, existing roof systems, base sheets, vapor retarders and other board stock with low-rise foam adhesives include polyisocyanurate, extruded and expanded polystyrene, high-density wood fiber, perlite, cellular glass and gypsum.

Boards should be flat, dry and free of surface contamination. Limiting rigid board insulation size to 4 by 4 feet is a common installation requirement intended to control the effects of internal material stresses that may cause cupping or bowing, particularly with larger insulation boards.

Facer material type and the strength of its lamination to the insulation core can be critical for overall adhesive bond strength.

For example, moisture levels inside roof assemblies can affect organic facer materials' cohesive strength. This has the potential to compromise insulation board attachment strength even if a good adhesive bond was achieved during roof system installation. If job-site conditions, building use or interior environment can be expected to drive moisture into a roof assembly, review insulation facer recommendations with the adhesive manufacturer.

Use recommendations

Recommendations for adhesive ribbon spacing from different manufacturers align well. Field-of-roof applications most frequently are spaced 12 inches on center. Recommendations for ribbon spacing in perimeter and corner roof areas range from 4 to 6 inches on center with 6 inches on center recommended most often.

This apparent agreement is a result of FM Approvals' influence in the realm of roof system specification and testing. Manufacturers look to FM Approvals' simulated uplift-resistance test method for roof assemblies adhered to concrete decks and use its maximum recommended adhesive ribbon spacing for field-of-roof applications. Also, FM Approvals' design guidelines call for doubling roof insulation attachment in perimeter and corner areas.

Similarities among manufacturers' recommendations generally do not extend to other important metrics observed during low-rise foam adhesive application and adhered component placement. For instance, requirements vary for minimum air and substrate temperature, ribbon width, and placing and walking-in boards.

Technicians working with low-rise foam adhesives need to be trained in application procedures provided by the manufacturer for the specific material being used. A well-trained individual experienced with the product being installed should be designated as a quality-control inspector during installation. Some industry experts also recommend making separate test cuts in roof sections installed in the morning and afternoon.

Manufacturers provide typical product coverage rates based on certain assumptions. These coverage rate values should be treated as approximations. Parameters such as ribbon width, substrate texture and adhesive temperature—in addition to ribbon spacing—control the coverage rate and should be part of technician training.

Ribbon spacing is easily controlled when using wheeled applicators designed for multibead application. Adhesive temperature should be maintained within the manufacturer's recommended range (typically 70 to 80 F) before application as this helps ensure a consistent material flow rate.

Roughly textured substrates, such as aggregate-surfaced BUR systems, may require increasing the application rate so sufficient adhesive is available to fill the space between the adhered surfaces. For poured and pumped adhesives, material temperature and rate of displacement above the substrate control the ribbon width. Products dispensed from pressurized containers are provided with application wands and valves that afford improved control over ribbon width.

Installation instructions for a majority of low-rise foam adhesives call for adhered component placement immediately after adhesive is applied. Exceptions include a sprayed one-component product formulated with hydrochlorofluorocarbon propellant, which calls for a delay of between two and eight minutes, and a poured one-component product, which in cold weather may require application of an accelerator solution before boards are set.

Manufacturers provide schedules for walking-in or ballasting insulation boards adhered with one-component products. These recommendations depend on substrate and ambient temperatures and air humidity.

One-component products may require several board walk-ins until adhesive reaches its setup time (the time to reach bond strength sufficient to support foot traffic and roof membrane installation). Boards rise slightly above the substrate surface between walk-ins as foaming action continues during extended curing periods. In cold temperatures or dry conditions, this can take more than 30 minutes. One manufacturer suggests adhesion tests with small amounts of adhesive and scrap insulation for estimating setup times in non-optimal conditions.

One-component products may take up to several days to achieve ultimate bond strength depending on conditions.

Manufacturers do not provide specific time intervals between setting down and walking-in or ballasting board stock for two-component products.

OMG Roofing Products, Agawam, Mass., provides typical setup times and the following guideline: "Board stock must be placed into the adhesive shortly after it has reached its maximum rise while it is still wet and tacky and before it reaches its tack-free state."

Setup times depend on temperature. Ultimate bond strength commonly takes less time to develop with two-component products because their curing does not depend on ambient moisture availability.

Uplift-resistance ratings

Compliance with building codes' wind uplift-resistance requirements for roof systems adhered with low-rise foam adhesives typically is substantiated through testing in accordance with ANSI/UL 1897, "Uplift Tests for Roof Covering Systems," or ANSI/FM 4474, "American National Standard for Evaluating the Simulated Wind Uplift Resistance of Roof Assemblies Using Static Positive and/or Negative Differential Pressures," which are incorporated into codes by reference. Underwriters Laboratories (UL) Inc. and FM Approvals conduct uplift-resistance tests and maintain databases of tested assembly listings. Other third-party testing and certification agencies provide similar services.

UL's online certification directory provides listings for assemblies using low-rise foam adhesives and constructed with steel, wood and concrete decks. UL's listings can be viewed by accessing www.ul.com, clicking the "Certifications" link and searching within UL category code TGIK (Roofing Systems, Uplift Resistance).

UL listings are based on testing in accordance with ANSI/UL 1897; the test method subjects a test assembly measuring a minimum of 10 by 10 feet to a series of increasing static uplift loads induced by air pressure differentials applied across it in one-minute intervals.

FM Approvals' online listings are available for assemblies using low-rise foam adhesives with structural concrete decks only. FM Approvals' RoofNav database provides access to the listings at www.roofnav.com.

Testing to obtain an FM approval listing for a roof assembly is conducted in accordance with FM 4470, "Approval Standard for Single-Ply, Polymer-Modified Bitumen Sheet, Built-Up Roof (BUR) and Liquid Applied Roof Assemblies for use in Class 1 and Noncombustible Roof Deck Construction." The standard specifies the Simulated Wind Uplift Pull Test Procedure for testing load resistances of assemblies with components adhered in ribbons of low-rise foam adhesive.

The test procedure is found in Appendix B of ANSI/FM 4474 and is intended for evaluating test assemblies using ribbon application of adhesive spaced 12 inches on center or less. During testing, a 2- by 2-foot assembly is subjected to a series of increasing static loads applied via mechanical means.

Test assemblies for use with both test methods are constructed and cured to meet low-rise foam adhesive manufacturers' specifications in controlled conditions.

Quality control required

Low-rise foam adhesives perform well, but they can be challenging. Successful applications depend on correctly managing the many application parameters affecting performance. Following manufacturer recommendations for specifying and installing low-rise foam adhesives can help avoid many potential problems. Project conditions outside installers' control also may interfere with adhesives' performance; such conditions should be reviewed with adhesive manufacturers.

For roof systems adhered with low-rise foam adhesives, NRCA recommends quality-control monitoring during installation by an individual knowledgeable of techniques and principles of foam adhesive application as the most reliable means to ensure installation requirements are met.

Maciek Rupar is an NRCA director of technical services.

COMMENTS

Be the first to comment. Please log in to leave a comment.