Low-slope edge-metal pieces can be joined in a number of ways—overlap, cover plate, concealed plate. The NRCA Roofing and Waterproofing Manual, Fifth Edition, provides several alternative joinery options for a number of edge-metal shapes in its Construction Details section.

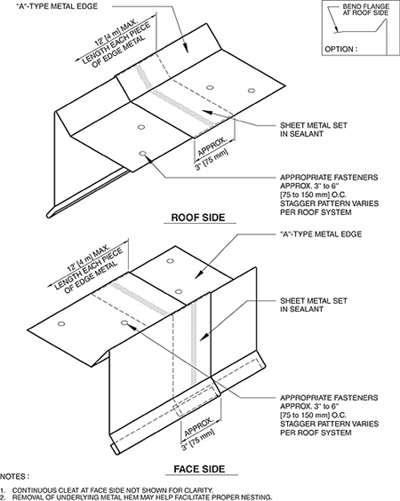

Detail SM-5, "'A' type edge metal with overlap," provides one of two methods to join two pieces of metal when using a gravel stop edge for low-slope roofing; the other method is a cover plate detail. A concealed plate joinery detail for the "A"-type edge metal is not provided because of the difficulty of nesting the concealed plate.

Edge metal is the first line of defense against uplift resistance. To provide adequate uplift resistance, a proper fastening schedule, as shown in the figure, is needed to adequately secure a flange to a wood nailer. (This assumes the wood nailer is secured properly to the top of the wall.) Proper fastening of a cleat and proper engagement of edge metal to a cleat also are critical elements for adequate uplift resistance. BUR-MB-Table 1 "Guide for sheet metal fascia edges for built-up and modified bitumen membranes" states the cleat is to be fastened at about 6 inches (150 mm) on center.

Detail SM-5 from The NRCA Roofing and Waterproofing Manual, Fifth Edition

An important element for weatherproofing a joint is the inclusion of sealant. Sealant should be continuous, thin (in depth) and wide to prevent moisture from entering the metal joint and still allow for some expansion and contraction of the metal. To limit movement of the metal pieces caused by temperature changes, the length of each piece of edge metal is limited to 12 feet (4 m).

As shown in the option box, slightly bending a flange downward reduces the chance that the end of a flange will be slightly raised after fastening. A raised flange end creates the potential for membrane damage where the flange and membrane are in direct contact.

Joinery details for fascia caps, "L"-type edge metal, "T"-type edge metal, coping caps, expansion-joint covers, valleys and gutters also are provided in the Sheet Metal section of Construction Details.

James R. Kirby, AIA, is an NRCA senior director of technical services.

COMMENTS

Be the first to comment. Please log in to leave a comment.