Wind resistance is an important performance property of asphalt shingle products and, depending on region, may be a significant consideration for building owners.

Until relatively recently, asphalt shingle products' wind resistances had been determined using a fan-induced wind test. Because of the long-standing nature of this wind test, virtually all asphalt shingle products have been tested and classified on this basis. But recently, a new wind-resistance methodology was developed and is beginning to be implemented. Currently, only a limited number of asphalt shingle products have been tested and are classified according to this new methodology.

There are important considerations you should be aware of if you use asphalt shingle products that are classified based on the new methodology.

Test methods

For more than 30 years, asphalt shingle products' wind resistances have been determined and classified based on one of two similar test methods: UL 997, "Standard for Wind Resistance of Prepared Roof Covering Materials," and ASTM D3161, "Standard Test Method for Wind-Resistance of Asphalt Shingles (Fan-Induced Method)."

When UL 997 and ASTM D3161 were initially developed, the designated fan velocity used in these tests was only 60 mph, which is representative of winds in the Beaufort Scale No. 10 range (55 mph to 63 mph). Until the mid- to late-1980s, this level of wind resistance generally was considered adequate for asphalt shingle products and most product warranties were based on this level of wind performance.

During the early 1990s, UL 997 and ASTM D3161 were revised to allow for testing and classifications at higher fan speeds, which are intended to be representative of higher wind speeds. As a result, asphalt shingles that pass the fan-induced wind test at 60 mph are designated as Class A; those that pass the test at 90 mph are designated as Class D; and those that pass the test at 110 mph are designated as Class F.

During the 1990s, building code officials and the insurance industry called for wind resistances at even higher levels for all roof systems, including asphalt shingle roof systems. But asphalt shingle manufacturers believed the fan-induced test would not be appropriate for the higher wind speeds being sought because of variances and turbulence in the fan-induced test at such high wind speeds. As a result, individual asphalt shingle manufacturers and the Asphalt Roofing Manufacturers Association (ARMA) began a long-term research project to develop a new methodology for testing, representing and classifying asphalt shingles' wind resistances.

In 1999, ASTM D6381, "Standard Test Method for Measurement of Asphalt Shingle Tab Mechanical Uplift Resistance," was published. And in 2003, Underwriters Laboratories (UL) Inc. published a new test standard, UL 2390, "Test Method for Wind-Resistant Asphalt Shingles with Sealed Tabs," that is based on ARMA's research.

UL 2390 and ASTM D6381 serve as the technical and testing basis for the new wind-resistance methodology.

UL 2390 is used to measure asphalt shingles' flexural moduli (stiffness), regions (areas) in front of and behind a shingle's self-seal strip(s), and pressure coefficients. An asphalt shingle's pressure coefficients are then multiplied by the areas, and an uplift force (load) on the asphalt shingle tab is determined.

ASTM D6381 is used to determine shingle resistance to uplift forces. The uplift-resistance value is compared with the shingle's uplift-force value (derived from UL 2390); a safety factor is added; and the appropriateness of a specific asphalt shingle for a specific wind speed is determined.

In 2006, ASTM D7158, "Standard Test Method for Wind Resistance of Sealed Asphalt Shingles (Uplift Force/Uplift Resistance Method)," was published. This standard combines the testing of UL 2390 and ASTM D6381 into a single standard and incorporates a classification system for representing tested asphalt shingles' wind resistances.

According to ASTM D7158, asphalt shingle products that are wind-resistant up to and including a 90-mph basic wind speed are classified as Class D; up to and including a 120-mph basic wind speed are classified as Class G; and up to and including a 150-mph basic wind speed are classified as Class H.

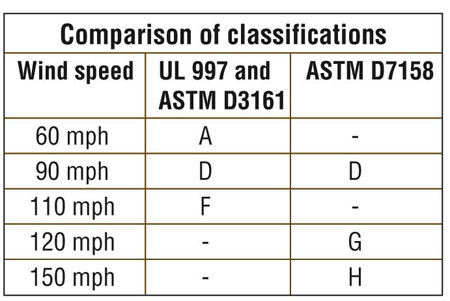

Figure 1: Comparison of wind-speed classifications

The classification system of ASTM D7158 correlates with that of UL 997 and ASTM D3161 as shown in Figure 1.

Product compliance

Review of NRCA's 2007-08 Steep-slope Roofing Materials Guide reveals there are at least 128 asphalt shingle products from nine manufacturers currently in the U.S. market. Seventy-two of these products are represented to have been tested according to UL 997 and/or ASTM D3161 for Class A (60 mph), Class D (90 mph) or Class F (110 mph) ratings.

Review of UL's Roofing Materials and Systems Directory and online certifications directory confirms the widespread classification of asphalt shingles based on UL 997 and/or ASTM D3161. Specifically, UL Category Code TFWZ, "Prepared Roof Covering Products," identifies asphalt shingle manufacturers and specific products that have been tested, classified and included in UL's labeling and follow-up service programs, ensuring ongoing compliance with the test methodology.

Regarding the new wind-resistance methodology, review of NRCA's materials guide reveals 44 asphalt shingle products from three manufacturers complied with UL 2390 and ASTM D6381 and/or ASTM D7158 when the materials guide was published.

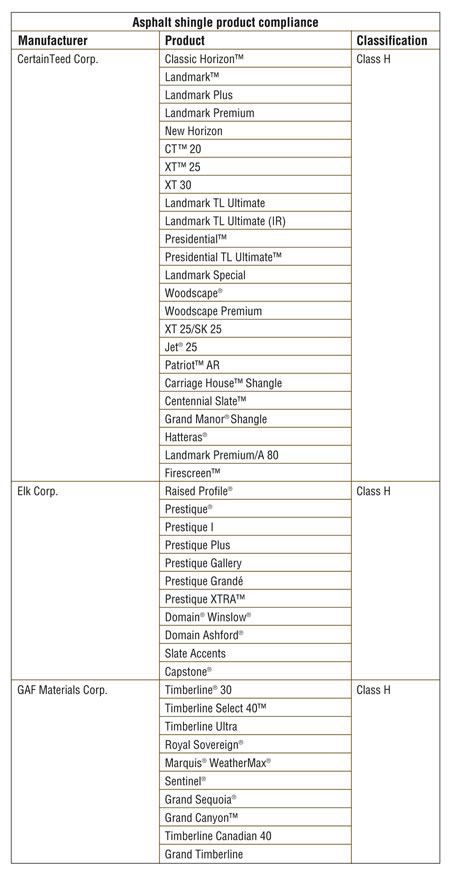

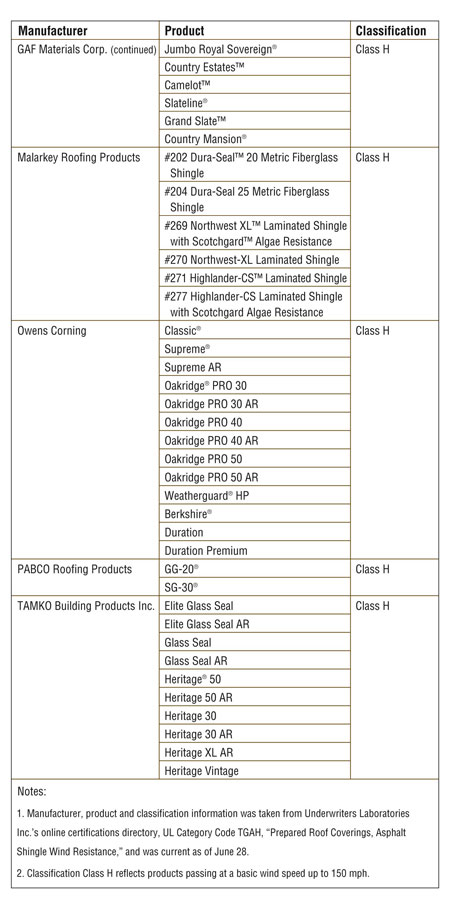

Figure 2: Manufacturers' and products' compliance with UL 2390/ASTM D6381 and/or ASTM D7158

UL's current online certifications directory, specifically UL Category Code TGAH, "Prepared Roof Coverings, Asphalt Shingle Wind Resistance," reveals 82 asphalt shingle products from seven manufacturers comply with UL 2390 and ASTM D6381 and/or ASTM D7158. The specific manufacturers and products that have been tested, classified and included in UL's labeling and follow-up service programs are identified in Figure 2.

The greater number of manufacturers and products listed in UL's certifications directory (compared with NRCA's materials guide) indicates manufacturers' recent testing, certification and implementation of the new wind-resistance methodology.

Important considerations

Regardless of the new methodology's increasing popularity, it is important to realize it has several notable limitations.

For instance, the methodology applies only to asphalt strip shingles with sealant whether the sealant is factory-applied or field-applied (hand-tabbed). The methodology specifically does not apply to unsealed asphalt strip shingles, including interlocking-type shingles, which do not have self-seal strips.

In addition, the calculation procedure on which the methodology is based contains some assumptions that somewhat limit the applicability of the methodology's classifications. Specifically, the calculation procedure assumes variables from ASCE 7, "Minimum Design Loads for Buildings and Other Structures," of Ka=1; Kb=0.000285; a building height of 60 feet or less; Exposure Categories A, B or C; and Building Use Categories I or II.

As a result, the new methodology does not apply when a building is taller than 60 feet; has an Exposure Category D (flat, unobstructed areas); or Building Use Categories III (schools, health care facilities, jails) or IV (essential facilities). These conditions usually result in the highest wind-uplift loads and need for the largest wind-uplift resistances.

Also, when considering UL-classified products, it is important to realize UL's classifications only apply to specific products manufactured in specific manufacturing facilities. In some instances, an asphalt shingle product produced in one manufacturing facility will be classified but a product from the same manufacturer and of the same product name produced in a different manufacturing facility may not be similarly classified.

You should consult asphalt shingle manufacturers regarding the availability of products classified by UL 2390 and ASTM D6381 and/or ASTM D7158 in your area.

Also, the only thing UL provides to verify the applicability of a UL classification to a specific product is the appearance of the UL listing mark on the product's packaging. In the case of products classified by UL for compliance with UL 2390 and ASTM D6381 and/or ASTM 7158, the product's UL listing mark will indicate "also classified in accordance with UL 2390/ASTM D6381 as to uplift resistance Class [indicating D, G or H]" or "also classified in accordance with ASTM D7158 as to uplift resistance Class [indicating D, G or H]."

Finally, application of asphalt shingles in accordance with the manufacturer's printed installation instructions is important for ensuring actual wind performance is consistent with the wind-resistance methodology's classifications. With the new wind-resistance methodology, proper asphalt shingle alignment, coursing and exposure are critical. Small variations in exposure beyond manufacturer tolerances significantly can affect a shingle's actual wind performance.

Interestingly, with the new methodology, attachment of asphalt shingles to a substrate has little effect on the shingles' wind resistances provided the fasteners do not adversely interfere with the shingles' sealant.

Choose carefully

The new wind-resistance methodology's implementation in the U.S. should prove useful, particularly in high-wind regions of the U.S. where many building owners are seeking increased levels of wind performance for asphalt shingle roof systems.

If you use asphalt shingle products classified according to the new methodology, carefully select appropriate products and beware of the considerations that apply to the methodology and product classifications.

Also, I encourage you to work closely with asphalt shingle manufacturers to identify and procure appropriately classified products.

Mark S. Graham is NRCA's associate executive director of technical services.