Complying with ANSI/SPRI ES-1, "Wind Design Standard for Edge Systems Used with Low Slope Roofing Systems," is required for edge-metal flashings (except gutters) for low-slope membrane roof systems in the 2003 and 2006 editions of the International Building Code (IBC). Therefore, it's important you become familiar with the standard.

Design wind loads

ANSI/SPRI ES-1 provides a means for determining design wind loads and testing wind resistances of metal gravel stops, fascias and copings. Determining design wind loads at a roof area's perimeter edges is accomplished by first determining the roof area's uplift pressure, factoring in an appropriate importance factor and applying appropriate external pressure coefficients applicable to roof area perimeter edges.

To determine a roof area's uplift pressure, the standard's look-up tables, which are based on building height, exposure category and basic wind speed applicable to the specific building and roof area being evaluated, can be used. An importance factor is applied to the velocity pressure, resulting in a value representative of the design wind-uplift load for the roof area's field.

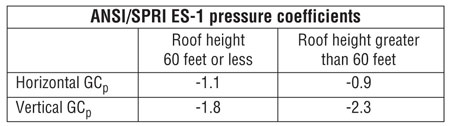

Vertical and horizontal perimeter edge pressure coefficients (GCps) provided in ANSI/SPRI ES-1 should be applied to this value for design wind-uplift load to determine design vertical and horizontal loads at a roof area's perimeter edges. These GCps are shown in the figure.

Pressure coefficients (GCps) applicable to roof area perimeter edges according to ANSI/SPRI ES-1

At perimeter corner regions, ANSI/SPRI ES-1 prescribes perimeter edge-metal flashings' fastener densities should be doubled to account for increased design wind-uplift loads in these areas.

Tested resistances

ANSI/SPRI ES-1 provides three test methods for determining edge-metal flashings' wind resistances:

According to ANSI/SPRI ES-1, perimeter edge-metal flashings are wind-resistant when their tested resistances are greater than the design vertical and horizontal loads at the perimeter edges for the roof area being evaluated.

Concerns with ES-1

Although ANSI/SPRI ES-1 is a consensus-based standard and incorporated into IBC, NRCA has several concerns with the standard.

ANSI/SPRI ES-1's requirement to double fastener densities in corner regions may be overly conservative in some instances and inadequate in others.

For example, when testing results in failure because of flexure in the metal (not attachment-related failure), doubling the fastener density will do little to adequately address the higher wind loads in the corner regions.

Also, ANSI/SPRI ES-1 does not require use of a safety factor when comparing tested resistance values with design wind-uplift loads. Use of a safety factor is commonplace in structural design to account for normally anticipated variances in loading, testing, materials and application.

For example, a safety factor of 1.67 typically is applied in the design of light-gauge steel and aluminum (metal panel roof systems). In other instances, larger safety factors may be appropriate.

NRCA hopes these issues can be appropriately addressed in the next edition of ANSI/SPRI ES-1, which is expected later this year.

Mark S. Graham is NRCA's associate executive director of technical services.

COMMENTS

Be the first to comment. Please log in to leave a comment.