Underwriters Laboratories (UL) Inc. has worked with the roofing industry for many years to test products for various performance characteristics. Although UL has been involved with roofing products for more than 100 years, there still is confusion within the roofing industry about UL's role and its various test methods. This article—the first of a two-part series—will concentrate on UL's history and various roofing activities, testing standards and requirements. Part two will concentrate on UL's Roofing Materials and Systems Directory and the UL Online Certifications Directory as it pertains to roofing materials and roof systems.

The beginning

UL is a product-safety testing, certification and standards-development organization that dates to 1894 when its founder, William Henry Merrill, had two employees and $350 worth of testing equipment in a small lab in Chicago. There, he opened Underwriters Electrical Bureau and conducted the first test on a noncombustible insulation material. By 1903, UL had conducted its first tests on roofing products.

Other significant UL events during the early 1900s included the following: Underwriters Electrical Bureau and Underwriters Bureau of Fire Protection incorporated as Underwriters Laboratories Inc.; Merrill and his chief engineer built the first fire test chamber to evaluate fire resistance of doors and windows; UL published its first standard, "Tin Clad Fire Doors"; UL issued its first product label (it was for a fire extinguisher); a label service was established for certain product categories that require more frequent inspections; and UL inspectors conducted their first factory inspections on labeled products at manufacturers' facilities.

In addition, during the early 1900s, UL certifications first were applied to many products, such as waste cans, automatic fire sprinklers, fire extinguishers and hoses, electric control panels, safety goggles and wooden safety matches, among others.

Since its early days, UL has continued to test many products and every roofing product imaginable. Currently, there are more than 18,000 types of products UL evaluates. UL is recognized as a leader in product safety testing and certification within the United States and has expanded its activities throughout the world.

Background

It is important to realize UL is an independent, not-for-profit organization; it is not part of the federal government. Manufacturers voluntarily submit products to UL for testing and safety certification.

Although there may not be building codes or fire codes that specify UL marks must be on roofing products, many municipalities' laws, codes and regulations require roofing products and roof systems be tested, listed and/or labeled by a nationally recognized certification organization before the products can be installed in a jurisdiction. Many roofing product manufacturers make it company policy to obtain UL certification for their products to minimize the possibility of nonacceptance by various authorities having jurisdiction. Some companies choose to obtain UL certification to minimize the safety risk that may be associated with their products.

Although commonly used, the term "UL-approved" is not an appropriate term because only authorities having jurisdiction can "approve" the use of a product. "UL-listed" and "UL-classified" are the applicable terms relative to UL certification of a product.

UL's listing mark on a product is the manufacturer's representation that samples of that product have been evaluated by UL for compliance with nationally recognized safety standards and found to be free from reasonably foreseeable risk of fire, electrical shock and related hazards. Prepared roof covering materials such as asphalt shingles, are UL-listed.

Most roofing materials and roof systems bear the UL classification mark, which is the manufacturer's representation that samples of that product have been evaluated for specific properties or suitability for use under specific conditions. Examples of UL's roofing classification programs include fire resistance, impact resistance, wind resistance, solar reflectance and thermal emittance, and uplift resistance.

It is important to note a product can be tested by UL but may not necessarily be certified by UL. Being UL-certified (listed or classified) means a product has been evaluated, complies with UL's requirements and is manufactured under UL's Follow-Up Service Program—not just tested by UL.

UL's Follow-Up Service Program verifies a manufacturer continues to produce products that comply with UL's requirements and according to the construction of the product that was originally evaluated and certified. To display a UL mark on a package or product, a manufacturer agrees to comply with manufacturing specifications and quality-control procedures. Under this agreement, UL's field representatives periodically test and/or examine products at factories and may select samples from the factory, the open market or elsewhere for further verification of compliance. By specifying UL-labeled roofing materials be used on a job, a roof system purchaser or roof system designer inherently obtains third-party quality control. In addition, if a problem with a UL-certified product is reported to UL, UL establishes a field report to determine the nature of the nonconformance and appropriate corrective action.

Roofing products and roof systems are divided into specific product categories. Each category has specified standards for product evaluation. UL uses a category control number (CCN) to designate and identify each product category in its printed product directory and online certification directory. For example, the CCN for roof covering materials is TEVT and the CCN for roof systems is TGFU. Following is information specific to the roofing categories.

Roof covering materials

Roof covering materials evaluated for external fire exposure are certified under the category TEVT, which addresses two basic types: prepared materials (applied directly to a roof deck according to manufacturer's instructions), and roof systems (assembly of several components). These roof coverings are evaluated to protect roof decks from external fire exposure. However, these roof coverings have not been evaluated for performance when exposed to a fire from an internal source directed onto a roof assembly's underside. Prepared materials further are subdivided into two categories, which follow:

The Roofing Systems category (TGFU) addresses the following types of systems:

It is important to note UL tests entire roof assemblies, including decks, insulation and membranes. Roof system designers and contractors should be extremely cautious when making substitutions for any of these components because unauthorized substitutions could void the UL certification. Roofing manufacturers meticulously test their materials with a variety of components to offer a choice of roof assemblies.

ANSI/UL 790

The standard used to evaluate roof covering materials and roof systems for resistance to external fire exposure is ANSI/UL 790, "Tests for Fire Resistance of Roof Covering Materials." The fire test method is similar to ASTM E108-04, "Standard Test Methods for Fire Tests of Roof Coverings," and NFPA 256, "Standard Methods of Fire Tests of Roof Coverings." These standards are the oldest and most common roofing standards.

ANSI/UL 790 is used to determine roofing materials' or a roof assembly's fire rating as Class A, B or C. These classes represent different levels of fire-resistance performance to external fire exposure (see Photo 1).

Class A roof coverings are effective against severe fire exposure. They are not readily flammable, do not carry or spread fire, and afford a fairly high degree of fire protection to the roof deck.

Class B roof coverings are effective against moderate fire exposure. They are not readily flammable, do not carry or spread fire, and afford a moderate degree of fire protection to the roof deck.

Class C roof coverings are effective against light fire exposure. They are not readily flammable, do not carry or spread fire, and afford some degree of fire protection to the roof deck.

ANSI/UL 790 includes three tests that evaluate a roof assembly's resistance to external fire exposure and burning materials that fall onto the roof covering from fires in adjacent areas. These tests include the spread-of-flame test, intermittent-flame test and burning-brand test. During all fire tests, there can be no flaming or glowing wood particles falling off the underside of the test deck; the roof deck cannot become exposed; and portions of the deck must not fall or break away in the form of glowing particles.

For all nonwood roof coverings or roof systems installed over a noncombustible deck, such as steel, concrete or gypsum, only the spread-of-flame test applies. During the test, a roof assembly is subjected to a 1400 F (760 C) flame carried by about a 12-mph (5.3-m/sec) wind for 10 minutes. To achieve a Class A rating, the flame must not spread beyond 6 feet (1.8 m), and to achieve a Class B rating, the flame spread is limited to 8 feet (2.4 m). For a Class C rating, the flame is reduced to 1300 F (704 C) and exposure time is reduced to four minutes. To achieve a Class C rating, the flame spread must not exceed 13 feet (3.95 m).

When a roof covering or roof assembly is intended for use over a combustible deck, the intermittent-flame test and burning-brand tests also are required to determine whether fire will penetrate a roof covering and components and ignite a deck's underside. During the intermittent-flame test, a roof assembly is subjected to the same 1400 F (760 C) flame as in the spread-of-flame test except the flame is turned on and off in two-minute cycles. To achieve a Class A rating, two successive assemblies must not burn through after 15 cycles. A Class B rating is earned when two samples successfully pass eight cycles. And a Class C rating is given when an assembly withstands three cycles of a 1300 F (704 C) flame turned on for one minute and off for two minutes.

The burning-brand test measures a roof assembly's ability to resist flame penetration from flaming embers. During the test, various-sized wooden brands are ignited and placed on a roof surface. The surface is exposed to a 12-mph (5.3-m/sec) wind. The test continues until the brands are consumed and all evidence of flame, glowing or smoke has disappeared from the top exposed surface and deck underside. For a Class A rating, one 12- by 12-inch (305- by 305-mm) wooden brand weighing about 4.4 pounds (2 kg) is used. For a Class B rating, the brand is 6 inches by 6 inches (152 mm by 152 mm) and weighs about 17.5 ounces (500 g). For a Class C rating, the sample is subjected to a combination of 25 burning brands; each weighs 0.32 ounces (9 g).

ANSI/UL 790 also includes a flying-brand test, rain test and weathering test. These tests are applied when evaluating wood shakes and shingles.

UL 997 and ASTM D3161

Prepared roof coverings under categories TFWZ and TFXX also can be evaluated and classified as to their wind resistances. The test standards used to evaluate wind resistance are UL 997, "Standard for Wind Resistance of Prepared Roof Covering Materials," and ASTM D3161, "Standard Test Method for Wind-Resistance of Asphalt Shingles (Fan-Induced Method)."

For the wind-resistance test, a test apparatus delivers a horizontal stream of air through a rectangular opening at 60 mph (28 m/s). The roof deck test panel is mounted on a carriage capable of being adjusted to various slopes, horizontal distances from the duct opening and angles incident to wind direction. The test described in UL 997 applies to prepared roof coverings that already comply with the requirements for construction, material specifications and performance, including fire resistance. When these roofing products are installed properly, they resist damage when subjected to winds of 55 mph-63 mph (24.5 m/s-28 m/s). A roof panel assembly successfully passes the test when the full shingle tabs are restrained from lifting or the locking ears, such as interlocking shingles, are not torn loose or disengaged during the two-hour test duration.

ASTM D3161 is similar to UL 997 except there are various classes of wind-resistance performance: Class A denotes a material passes at a wind velocity of 60 mph (28 m/s); Class D denotes a material passes at a wind velocity of 90 mph (40 m/s); and Class F denotes a material passes at a wind velocity of 110 mph (49 m/s).

UL 2390

A relatively new category evaluates asphalt shingles for wind resistance through a "calculation method." The category is Prepared Roof Covering Materials, Asphalt Shingle Wind Resistance (TGAH). Using UL 2390, "Test Method for Wind Resistant Asphalt Shingles with Sealed Tabs," UL certifies asphalt shingles for wind-resistance classifications up to 150 mph (67 m/s). Research leading to development of UL 2390 was initiated to address the behavior of asphalt shingles under various wind loads. The goal was to develop a prediction model for asphalt shingles to improve shingle wind-resistance performance with a focus on the tab sealant. The Asphalt Roofing Manufacturers Association sponsored the research that was conducted by wind-engineering experts and other interested parties. UL participated in a review capacity, and the UL 2390 test standard is an outgrowth of that research work.

For the evaluation procedure, asphalt shingles first are affixed using a tab sealant that represents the intended application. Then, using moderate air flow (35 mph [16 m/s]) across a shingle surface, the shingle's wind-uplift coefficient is calculated by measuring the pressures above and below the shingle surface at the windward and leeward sides of the sealant strip. Next, the potential uplift force acting on the tab sealant is calculated based on the wind-speed classification selected for the investigation.

Once this potential uplift force is determined, the tab sealant's actual uplift-resistance capability is measured using ASTM D6381, "Standard Test Method for Measurement of Asphalt Shingle Mechanical Uplift Resistance." The uplift-resistance force determined from this mechanical test method is required to be equal to or greater than the calculated uplift force for the corresponding wind-speed classification. The wind-speed classifications are Class D—90 mph (40 m/s), Class G—120 mph (53 m/s) and Class H—150 mph (67 m/s).

UL has completed several product certification projects using this procedure and UL 2390. Contractors, engineers, architects and authorities having jurisdiction will see these UL-classified roofing products in field applications.

UL 2218

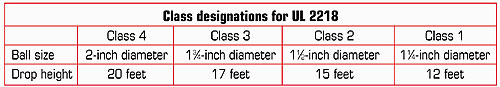

To evaluate a roofing product's resistance to impact, UL 2218, "Impact Resistance of Prepared Roof Covering Materials," is used. Roofing products must survive the assigned class designation impact without visible evidence of tearing, fracturing, cracking, splitting, rupture, crazing or other opening of the roof covering layer. See Figure 1 for class designations according to ball size and height of ball drop. The effects of weathering on these materials' impact resistances have not been investigated.

Figure 1: Class designations from UL 2218

These UL-certified products are published under the UL category Roof Covering Materials, Impact Resistance (TGAM). To be eligible for classification in this category, roof covering materials also must be listed under Prepared Roof Covering Materials (TFWZ) or Prepared Roof Covering Materials, Formed or Molded Metal, Fiber-Cement, Plastic or Fire Retardant-treated Wood (TFXX) or classified under Roofing Systems (TGFU).

Some insurance companies require this certification program to minimize risks relative to hail damage.

UL 1897

Roofing Systems, Uplift Resistance under category TGIK includes products evaluated for uplift resistance. This should not be confused with the previously referenced wind-resistance categories. Whereas wind-resistance tests evaluate roof assemblies for resistance to various wind velocities, uplift tests subject roof coverings to various static pressures that would be associated with high winds. Wind uplift occurs when wind passing over a building reduces air pressure over a roof until it is less than the air pressure inside the building. This uplift-resistance category is related exclusively to the securement of the roof covering to a specified type of roof deck.

The test standard is UL 1897, "Uplift Tests for Roof Covering Systems." In this test, roof coverings are installed as intended for the field over deck substrates. The test sample is placed in a 10- by 10-foot (3- by 3-m) roof assembly frame and subjected to static pressures. The pressures begin at 15 pounds per square foot (psf) (7.32 kg/m²), and the test continues with multiple phases of 15-psf (7.32-kg/m²) increments held for one-minute durations.

The roof assembly rating is the maximum static negative pressure sustained for one minute without failure.

It is important to note for these roof uplift categories that the magnitude of wind velocity across a roof deck and resulting uplift pressures on a roof deck depend on many factors, such as wind gusts, roof deck shape, edge configuration and landscape surrounding the roof deck installation.

A method to calculate the uplift pressures on roof decks is contained in ASCE 7-95, "Minimum Design Loads for Buildings and Other Structures."

Roof deck constructions

Roof Deck Constructions under category TGKX addresses two types of product evaluations: uplift resistance of roof deck constructions and exposure of a roof deck construction to an internal fire exposure. Roof deck constructions evaluated for uplift resistance are classified and have been investigated for damageability from external and internal static pressures on the deck associated with high-velocity winds.

UL 580

Uplift classifications are derived from tests conducted according to UL 580, "Standard for Tests For Uplift Resistance of Roof Assemblies." UL 580 is similar to UL 1897 except UL 580 subjects a 10- by 10-foot (3- by 3-m) test sample to various positive and negative static and oscillating air pressures to index performance under uplift loads imposed on roof decks. UL 580 provides a comparative measure of uplift resistance of roof deck constructions. The test evaluates a roof deck or roof deck assembly and its attachment to supports, as well as the attachment of the roof covering, if used.

Classifications under Roofing Systems, Uplift Resistance (TGIK) covers uplift resistance related exclusively to the securement of the roof covering to a specified type of roof deck.

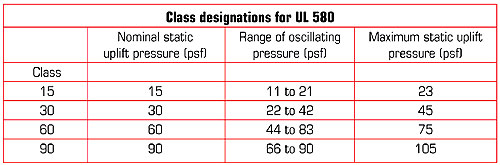

There also are performance classes for roof deck constructions evaluated for their uplift resistances. The nominal static uplift pressure, oscillating uplift pressures and maximum static uplift pressure for each class are shown in Figure 2.

Figure 2: Class designations from UL 580

The static pressures are maintained for a five-minute period, and the oscillating pressures are maintained for a 60-minute period for each class. A roof assembly rated Class 60 successfully has withstood pressures imposed during Class 30 and Class 60 tests. A roof assembly rated Class 90 successfully has withstood pressures imposed during Class 30, Class 60 and Class 90 tests.

Several of the classified components of roof decks have their own product categories. Some more common examples are Metal Roof Deck Panels (TJPV), Roof Deck Fasteners (TLSX), Building Units (skylights) (TIAR) and Foamed Plastic (TJBX).

During UL 580 tests, supporting structural members are evaluated only with respect to spacing and physical properties such as gauge; yield strength; grade and species of lumber; and related factors, which could affect fastener attachment and necessary resistance to uplift forces. Secondary supports (beams, purlins, joists, bulb tees, lateral bracing, etc.); connections of the assembly to the main structural members (girders, columns, etc.); and construction details along roof edges and around openings (skylights, chimneys, etc.) have not been evaluated unless specified in the construction. Constructions including skylights have been evaluated with single-width skylight panels flanked on each side by a metal panel. Constructions including eaves/soffit have been evaluated for resistance to uplift pressures on the underside only.

UL 1256

UL 1256, "Standard for Fire Test of Roof Deck Constructions," is a widely recognized test method used to determine roof assemblies' fire resistances to internal fire exposure. The test method evaluates the performances of metallic and nonmetallic roof deck constructions subjected to internal (under deck) fire exposures to determine the contribution of the roof covering material, insulation and other roof system components to the spread of fire within a building.

UL 1256 contains two test methods that are described in Parts I and II of the standard. One of these test methods is selected by UL based on assessment of fire test experience as outlined in the standard.

Part I describes a large-scale fire test method to evaluate roof deck constructions that, by experience in actual installations, were known to have contributed extensively to underdeck fire spread. The large scale test structure measures 20-foot- (6-m-) wide, 100-foot- (30-m-) long by 10-foot- (3-m-) high. The structure was built out of masonry and painted white, so the test is referred to as "The White House Test." One 20-foot- (6-m-) wide end (the flue end) remains open. On the opposite end, fire exposure is delivered whereby exposure temperatures increase with time according to a standard time-temperature relationship. The test duration is 30 minutes. The maximum sustained flame front and falling flaming residue within the structure as a result of under deck flaming shall not exceed 60 feet (18 m) from the fire end during the 30-minute test period.

Part II describes a smaller-scale fire test method whereby the Steiner fire test chamber is used to evaluate roof deck constructions for resistance to underdeck fire spread (see Photo 2). The Steiner test chamber method uses a 17 3/4-inch- (451-mm-) wide, 25-foot- (7.6-m-) long, 12-inch- (305-mm-) high test apparatus. The flame propagation on the underside of each assembly tested shall not have exceeded 10 feet (3 m) in 10 minutes or 14 feet (4.3 m) in 30 minutes. The conditions of acceptance under Part II were established by analyzing correlative data developed on a specific construction that exhibited adequate performance in the large-scale test method.

UL 263

Some roofing materials are evaluated in Fire Resistive Constructions using UL 263, "Standard for Fire Tests of Building Construction and Materials." This test method also evaluates a roof-ceiling assembly's ability to withstand exposure to an internal fire. These roof-ceiling fire-resistance designs begin with the letter "P" in UL's Fire Resistance Directory.

Tested assemblies must remain intact and prevent excessive flames and heat from penetrating through to a roof's exterior. Thermocouples measure the temperature of the outer roof membranes and ceiling supports. Interior exposure temperatures increase with time according to a standard time-temperature relationship. Throughout the fire-endurance test, a superimposed load is applied to the roof assembly to simulate a maximum load condition. Hourly fire-resistive ratings are achieved based on the length of time the assembly withstands the fire exposure and passes the performance requirements. The surface temperature on the external surface of the roof assembly must not exceed an average increase of 250 F (121 C).

A new category

Last but not least is UL's relatively new category, Roof Covering Materials, Solar Reflectance (TGFE). This category addresses low- and steep-slope roofing products' surface radiative properties.

Solar-reflectance measurements are made according to ASTM C1549, "Standard Test Method for Determination of Solar Reflectance Near Ambient Temperature Using a Portable Solar Reflectometer." UL tests thermal emittance according to ASTM C1371, "Standard Test Method for Determination of Emittance of Materials Near Room Temperature Using Portable Emissometers."

A 0.00 value represents no measured reflectance or radiative energy emission. A 1.00 value represents 100 percent measured reflectance or emission. This UL program provides manufacturers with a credible means of supplying data to substantiate their products' compliance with the U.S. Environmental Protection Agency's ENERGY STAR® program and possibly labeling requirements of the Cool Roof Rating Council.

Looking ahead

UL looks forward to a future of testing and certification in the roofing arena. Next month, I will discuss UL's Roofing Systems Directory and Online Certifications Directory.

Dwayne E. Sloan is principal engineer, Building Materials, Roofing Materials & Systems, and Air Ducts, for Underwriters Laboratories Inc.

UL facts and figures

As of 2003 ...

19 billion UL Marks appeared on products.

68,713 manufacturers produced UL-certified products.

UL conducted 103,286 product evaluations.

UL evaluated 18,850 types of products.

UL conducted 547,708 follow-up visits to audit compliance with product certification requirements.

127 UL inspection centers existed.

UL customers were in 99 countries.

UL reached 143.1 million consumers with safety messages in the United States and Canada.

There were 876 UL Standards.

UL registered 5,607 facilities to a management system standard as of Dec. 31, 2003.

60 laboratory, testing and certification facilities were part of the UL family of companies.

More than 6,023 staff of the UL family of companies served UL customers.

UL 790 history

Of the many UL roofing standards published, UL 790, "Standard for Tests for Fire Resistance of Roof Covering Materials," is the oldest and most widely used. This standard sets the minimum requirements for the evaluation of a roof assembly's ability to resist fire exposure from the outside. UL's Class A, Class B or Class C designations classify successfully tested assemblies—Class A roof assemblies have the greatest fire resistance.

More than a century ago, UL conducted its first roofing test for resistance to an external fire. Since then, UL has tested a plethora of roofing products and developed several roofing standards that evaluate and measure specific characteristics of roofing materials and roof systems with respect to fire safety and/or property protection. These standard-development activities and testing always have been carried out with the roofing industry.

By 1910, UL had begun full-scale roof system testing. Through 1917, UL continued to test and classify roofing materials according to early standards that had been based on the original testing. The overall intent of the early standard was to have a standardized evaluation of roof coverings with regard to their ability to resist ignition, fire spread and fire penetration from exterior fires. This early standard included the following tests:

The early standard also contained a durability research study to look at the quality of the raw materials employed, weathering qualities and necessity for repairs.

Originally, there were five classifications—A through E. By 1917, UL dropped to three classes—A, B and C. Around this same time, UL adopted standard specifications for shingle roof covering investigations in UL 55B, "Class C Asphalt Organic-Felt Sheetroofing and Shingles." And by 1924, UL had tested a new asphalt roofing product.

In 1955, ASTM International first published ASTM E108, "Standard Test Methods for Fire Tests of Roof Coverings," as a tentative standard. The main objective was to incorporate UL-based test requirements as a test method, excluding the performance criteria. The classifications A, B and C were used to designate classes of fire test exposure rather than classes of roof coverings.

In 1958, UL published the first edition of UL 790, "Tests for Fire Resistance of Roof Covering Materials." That same year, the National Fire Protection Association (NFPA) also adopted and published the test method as NFPA 256, "Standard Methods of Fire Tests of Roof Coverings." Since the late 1950s, these standards have been updated and revised. However, the revisions are considered primarily editorial.

COMMENTS

Be the first to comment. Please log in to leave a comment.