Building owners and roof system designers who are comparing two or more roof membrane types often ask the NRCA Technical Services team: “Which is better?”

The applicable ASTM International product standard and manufacturers’ product literature help make such determinations. To illustrate the point, I will use PVC and KEE as examples.

Product standards

The U.S. product standard for PVC sheet membranes is ASTM D4434, “Standard Specification for Poly(Vinyl Chloride) Sheet Roofing.” The standard provides three classifications: Types II, III and IV. Type I, originally reserved for unreinforced sheet, is no longer applicable because the product has since been removed from the market.

Type II products are reinforced with fibers that have been incorporated into the production process. The fibers act as a carrier and do not appreciably affect physical property characteristics of the finished product (such as tensile strength or ultimate elongation) but may provide other desirable characteristics, such as dimensional stability.

Type III products are internally reinforced with fabric; in addition, they may have fabric backings.

Type IV products are internally reinforced with fabric and may have 36-mil minimum thickness fabric backings.

PVC sheets complying with the standard consist of PVC resin in amounts greater than 50% of the total polymer content compounded with plasticizers, stabilizers, fillers, pigments and other ingredients to satisfy the standard’s physical property requirements and accelerated weathering tests.

The U.S. product standard for KEE sheet membranes is ASTM D6754, “Standard Specification for Ketone Ethylene Ester Based Sheet Roofing.” It has no classifications.

KEE products complying with the standard are internally reinforced with fabric and consist of polymers and other compounding ingredients with the KEE polymer being a minimum 50% by weight of the polymer content of the sheet.

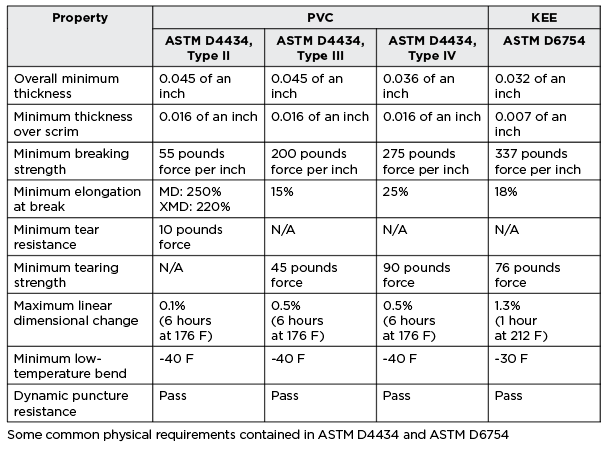

Some common physical requirements contained in ASTM D4434 and ASTM D6754 are shown in the figure.

ASTM D4434’s Types II and III physical requirements are based on minimum 45-mil sheet thicknesses, and Type IV is based on a 36-mil sheet thickness. ASTM D6754 is based on a minimum 32-mil sheet thickness. Other PVC and KEE membrane sheet thicknesses are available. Additional membrane thickness can affect some physical properties, including thickness over scrim, tear resistance and tear strength.

Product literature

Manufacturers vary on how they present their products’ physical property values in product literature. Some manufacturers reference only the applicable product standard without referencing specific physical property information; other manufacturers provide some physical property data. Depending on the manufacturer, the physical property data provided may simply restate the minimum or maximum allowable values from the applicable product standard. Other manufacturers provide product data showing their products exceed the product standards’ minimum requirements.

Manufacturers typically consider PVC-KEE-alloy products that have KEE polymer content less than ASTM D6754’s minimum 50% by weight comply with ASTM D4434. These products, depending on their KEE content, typically have some KEE-like physical properties. With these products, reviewing their physical property values can be particularly helpful when making comparisons.

Closing thoughts

I encourage manufacturers to include ASTM International product standard designations—including any applicable type, class or grade classifications—in product literature. Also, manufacturers should include product-specific physical property data using the test method standards included in the applicable product standard.

Additional information about membrane products, including the applicable ASTM International product standards, is provided in The NRCA Roofing Manual: Membrane Roof Systems. You can purchase or download the manual (free for NRCA members) at shop.nrca.net.

MARK S. GRAHAM is NRCA’s vice president of technical services.

@MarkGrahamNRCA