Energy-efficient roofing materials are becoming more popular, but most commercially available products are geared toward the low-slope sector. However, research and development are taking place to produce "cool" residential roofing materials.

In 2002, the California Energy Commission asked Lawrence Berkeley National Laboratories (LBNL), Berkeley, Calif., and Oak Ridge National Laboratories (ORNL), Oak Ridge,Tenn., to collaborate with a consortium of 16 manufacturing partners and develop "cool" non-white roofing products that could revolutionize the residential roofing industry.

The commission's goal is to create dark shingles with solar reflectances of at least 0.25 and other nonwhite roofing products—including tile and painted metal—with solar reflectances not less than 0.45. The manufacturing partners have raised the maximum solar reflectance of commercially available dark products to 0.25-0.45 from 0.05-0.25 by reformulating their pigmented coatings. (For a list of the manufacturers, see "Manufacturing partners," page 36.)

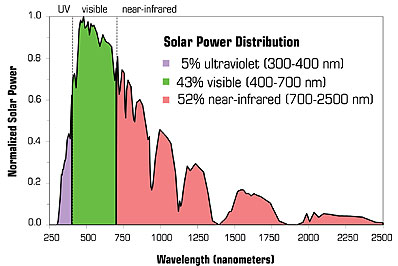

Because coatings colored with conventional pigments tend to absorb invisible "near-infrared" (NIR) radiation that bears more than half the power of sunlight (see Figure 1), replacing conventional pigments with "cool" pigments that absorb less NIR radiation can yield similarly colored coatings with higher solar reflectances. These cool coatings lower roof surface temperatures, reducing the need for cooling energy in conditioned buildings and making unconditioned buildings more comfortable.

Figure courtesy of the Lawrence Berkeley National Laboratories, Berkeley, Calif.

Figure 1: Peak-normalized solar spectral power—more than half of all solar power arrives as invisible, "near-infrared" radiation

Cool, nonwhite roofing materials are expected to penetrate the roofing market within the next three years to five years. Preliminary analysis by LBNL and ORNL suggests the materials may cost up to $1 per square meter more than conventionally colored roofing materials. However, this would raise the total cost of a new roof system only 2 percent to 5 percent.

Cool, nonwhite colors

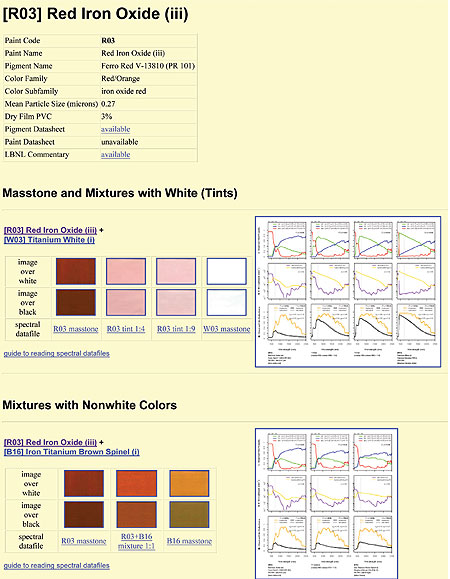

Developing the colors to achieve the desired solar reflectances involves much research and development. So far, LBNL has characterized the optical properties of 87 common and specialty pigments that may be used to color architectural surfaces. Pigment analysis begins with measurement of the reflectance—r—and transmittance—t—of a thin coating, such as paint film, containing a single pigment, such as iron oxide red. These "spectral," or wavelength-dependent, properties of the pigmented coating are measured at 441 evenly spaced wavelengths spanning the solar spectrum (300 nanometers to 2,500 nanometers).

Inspection of the film's spectral absorptance (calculated as 1-r-t) reveals whether a pigmented coating is "cool" (has low NIR absorptance) or "hot" (has high NIR absorptance). The spectral reflectance and transmittance measurements also are used to compute spectral rates of light absorption and backscattering (reflection) per unit depth of film. The spectral reflectance of a coating colored with a mixture of pigments then can be estimated from the spectral absorption and backscattering rates of its components.

LBNL has produced a database detailing the optical properties of the 87 characterized pigmented coatings (see Figure 2). Its researchers are developing coating formulation software intended to minimize NIR absorptance (and maximize the solar reflectance) of a color-matched pigmented coating. The database and software will be shared with the consortium manufacturers later this year.

Figure courtesy of Lawrence Berkeley National Laboratories, Berkeley, Calif.

Figure 2: Description of a red iron oxide pigment in the Lawrence Berkeley National Laboratory pigment database

Shingles

A new shingle's solar reflectance is dominated by the solar reflectance of its granules, which cover more than 97 percent of its surface. Until recently, the way to produce granules with high solar reflectance has been to use a coating pigmented with titanium dioxide (TiO2) white. Because a thin TiO2-pigmented coating is reflective but not opaque in NIR, multiple layers are needed to obtain high solar reflectance. Thin coatings colored with cool, nonwhite pigments also transmit NIR radiation. Any NIR light transmitted through the pigmented coating will strike the granule aggregate where it will be absorbed (typical dark rock) or reflected (typical white rock).

Multiple color layers, a reflective undercoating and/or reflective aggregate can increase granules' solar reflectances, thereby increasing shingles' solar reflectances.

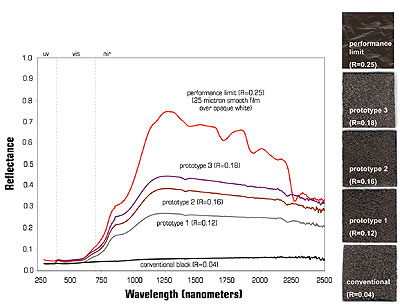

Figure 3 shows the iterative development of a cool black shingle prototype by ISP Minerals Inc., Hagerstown, Md. A conventional black roof shingle has a reflectance of about 0.04. Replacing the granule's standard black pigment with a cool NIR-scattering black pigment (prototype 1) increases the solar reflectance of the shingle to 0.12. Incorporating a thin white sublayer (prototype 2) raises the shingle's solar reflectance to 0.16; using a thicker white sublayer (prototype 3) increases the shingle's reflectance to 0.18. The figure also shows an approximate performance limit (solar reflectance 0.25) obtained by applying 25-micron NIR-reflective black topcoat over an opaque white background.

Figure courtesy of Lawrence Berkeley National Laboratories, Berkeley, Calif.

Figure 3: ISP Minerals Inc., Hagerstown, Md., is developing a cool, black shingle. Shown are the solar spectral reflectances, images and solar reflectances (R) of a conventional black shingle; three prototype cool, black shingles; and smooth, cool, black film over an opaque white background.

Tile

There are three ways to improve solar reflectances of colored tiles: use clay or concrete with low concentrations of light-absorbing impurities, such as iron oxides and elemental carbon; color tile with cool pigments contained in a surface coating or mixed integrally; and/or include an NIR-reflective sublayer, such as a white sublayer, beneath an NIR-transmitting colored topcoat.

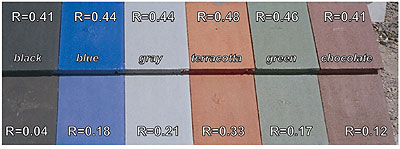

American Rooftile Coatings, Fullerton, Calif., has developed a palette of cool, nonwhite coatings for concrete tiles. Each of its COOL TILE IR COATINGS™ shown in Figure 4 has a solar reflectance greater than 0.40. The solar reflectance of each cool coating exceeds that of a color-matched, conventionally pigmented coating by 0.15 (terra cotta) to 0.37 (black).

Metal

Cool, nonwhite pigments can be applied to metal with or without a white sublayer. If a metal is highly reflective, the sublayer may be omitted. The polymer coatings on metal panels are kept thin to withstand bending. This restriction on coating thickness limits pigment loading (pigment mass per unit surface area).

Performance research

ORNL naturally is weathering various types of conventionally pigmented and cool-pigmented roofing products at seven California sites. Each "weathering farm" has three south-facing racks for exposing samples of roofing products at typical roof slopes. Sample weathering began in August 2003 and will continue for three years—until October 2006. Solar reflectance and thermal emittance are measured twice per year; weather data are available continuously. Solar spectral reflectance is measured annually to gauge soiling and document imperceptible color changes.

ORNL and the consortium manufacturers also are exposing roof samples to 5,000 hours of xenon-arc light in a weatherometer, a laboratory device that accelerates aging via exposure to ultraviolet radiation and/or water spray. ORNL will examine the naturally weathered samples for contaminants and biomass to identify the agents responsible for soiling. This may help manufacturers produce roofing materials that better resist soiling and retain high solar reflectance. Changes in reflectance will be correlated to exposure.

The labs and manufacturing partners also have established residential demonstration sites in California. The first, in Fair Oaks (near Sacramento), includes two pairs of single-family, detached homes. One pair is roofed with color-matched conventional and cool-painted metal shakes supplied by Custom-Bilt Metals, South El Monte, Calif., and the other features color-matched conventional and cool low-profile concrete tiles supplied by Hanson Roof Tile, Charlotte, N.C. The second site, in Redding, is under construction and by summer will have a pair of homes roofed with color-matched conventional and cool asphalt shingles.

Figure courtesy of American Rooftile Coatings.

Figure 4: This is a palette of color-matched cool (top row) and conventional (bottom row) roof tile coatings developed by American Rooftile Coatings, Fullerton, Calif. Shown on each coated tile is its solar reflectance.

The homes in Fair Oaks are adjacent and share the same floor plan, roof orientation and level of blown ceiling insulation (19 hr•ft²•ºF/Btu). The homes in Fair Oaks and Redding will be monitored through at least summer 2006.

One of the Fair Oaks homes roofed with low-profile concrete tile was colored with a conventional chocolate brown coating (solar reflectance 0.10), and the other was colored with a matching cool chocolate brown (an American Rooftile Coatings COOL TILE IR COATING™ with solar reflectance 0.41). The attic air temperature beneath the cool brown tile roof has been measured to be 3 K to 5 K cooler than that below the conventional brown tile roof during a typical hot summer afternoon (273.15 K equals 0 C).

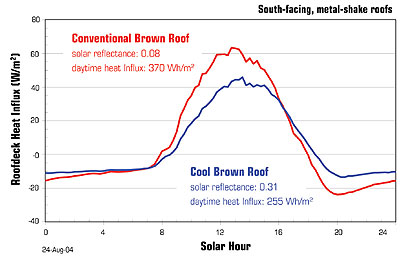

The results for the pair of Fair Oaks homes roofed with painted metal shakes are just as promising. There, the attic air temperature beneath the cool brown metal shake roof (solar reflectance 0.31) was measured to be 5 K to 7 K cooler than that below the conventional brown metal shake roof.

These reductions in attic temperature are solely the result of the application of cool, colored coatings. The use of these cool, colored coatings also decreased the total daytime heat influx (solar hours are from 8 a.m.-5 p.m.) through the west-facing concrete tile roof by 4 percent and the south-facing metal shake roof by 31 percent (see Figure 5).

Figure courtesy of Oak Ridge National Laboratory, Oak Ridge, Tenn.

Figure 5: Heat flows through the roof decks of an adjacent pair of homes during the course of a hot summer day. The total daily heat influx through the cool brown metal shake roof (solar reflectance 0.31) between the solar hours of 8 a.m. and 5 p.m.is 31 percent lower than through the conventional brown metal shake roof (solar reflectance 0.08).

ORNL also is testing several varieties of concrete and clay tile on a steep-slope roof to further investigate the individual and combined effects of cool, colored coatings and subtile ventilation on the thermal performance of a cool roof system.

Results to date

The two laboratories and their industrial partners have achieved significant success in developing cool, colored materials for concrete tile, clay tile and metal roofs.

Since the inception of this program, the maximum solar reflectances of commercially available dark roofing products has increased to 0.25-0.45 from 0.05-0.25. Bi-layer coating technology (a color topcoat over a white or other highly reflective undercoat) is expected to soon yield several cost-effective cool, colored shingle products with solar reflectances in excess of the U.S. Environmental Protection Agency's ENERGY STAR® threshold of 0.25. Early monitoring results indicate using cool, colored roofing products measurably reduces heat flow into conditioned homes with code-level ceiling insulation.

As homeowners continue to seek energy-efficient products, the roofing industry's research into residential roofing products that offer energy-efficient features naturally will continue to evolve.

Provided energy-efficient products continue to perform satisfactorily, we expect cool, nonwhite metal, tile and shingle products to penetrate the roofing market within the next three to five years.

Hashem Akbari leads LBNL's Heat Island Group. André Desjarlais leads ORNL's Building Envelope Group.

Editor's note: Ronnen Levinson, scientist, Paul Berdahl, staff scientist, and Stephen Wiel, staff scientist, of LBNL; William Miller senior research engineer of ORNL; and Nancy Jenkins, program manager, Arthur Rosenfeld, commissioner, and Chris Scruton, project manager, of the California Energy Commission contributed to this article.

Manufacturing partners

3M

St. Paul, Minn.

www.scotchgard.com/roofinggranules

Akzo Nobel

Felling, United Kingdom

www.akzonobel.com

American Rooftile Coatings

Fullerton, Calif.

www.americanrooftilecoatings.com

BASF Industrial Coatings

Florham Park, N.J.

www.ultra-cool.basf.com

CertainTeed Corp.

Valley Forge, Pa.

www.certainteed.com

Custom-Bilt Metals

South El Monte, Calif.

www.custombiltmetals.com

Elk Corp.

Dallas

www.elkcorp.com

Ferro Corp.

Cleveland

www.ferro.com

GAF Materials Corp.

Wayne, N.J.

www.gaf.com

Hanson Roof Tile

Charlotte, N.C.

www.hansonrooftile.com

ISP Minerals Inc.

Hagerstown, Md.

MCA Tile

Corona, Calif.

www.mca-tile.com

MonierLifetile LLC

Irvine, Calif.

www.monierlifetile.com

Owens Corning

Toledo, Ohio

www.owenscorning.com/around/roofing/Roofhome.asp

Shepherd Color Co.

Cincinnati

www.shepherdcolor.com

Steelscape Inc.

Kalama, Wash.

www.steelscape-inc.com