A critical detail for a low-slope structural metal panel roof system is a valley because that is where water is collected and routed off a roof system. The NRCA Architectural Sheet Metal and Metal Roofing Manual, 2006 Edition, provides four valley details. Detail S-MTL-9A, Open Valley Metal With Side Locks (Cleated), is one way to weatherproof a valley.

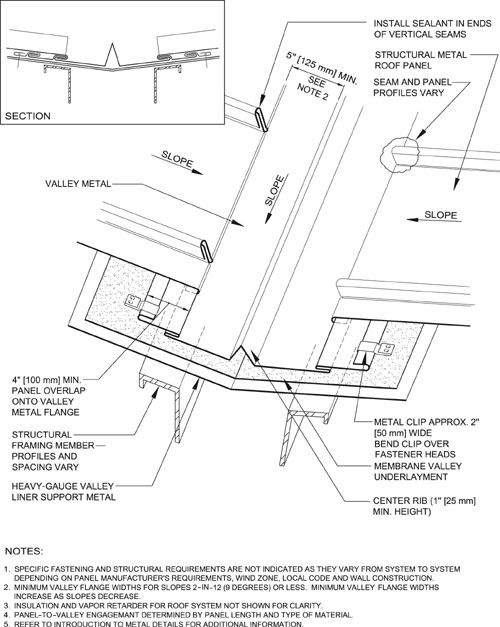

In the detail, the ends of the structural metal panels and valley metal are supported by a heavy-gauge valley liner support metal, which is carried by the structural framing members. The support metal placed directly under the panel ends limits deflection and provides a stable base for a long-term weatherproof detail.

Before you install valley metal, you must install a membrane valley underlayment on top of the support metal to help prevent water intrusion.

The valley metal's center rib is required to be at least 1 inch in height but may be as tall as the vertical seams of the metal panels. This rib helps prevent water from running across the width of the valley metal and directs water to drains, scuppers or gutters.

Detail S-MTL-9A from The NRCA Architectural Sheet Metal and Metal Roofing Manual, 2006 Edition

NRCA recommends this valley have 5-inch minimum clearance between the center rib and bottom edge of the metal panels. This dimension is based on a roof slope of 2-in-12 (9 degrees) and should increase as the slope decreases to accommodate a greater accumulation of slower-moving water. However, there is no specific method to determine the required increase. It is prudent to determine the width of the valley metal based on the width of available coil or flat stock; contractor-fabricated valleys generally are fabricated from coil or flat stock. Most premanufactured valleys can be provided in various sizes.

The valley metal is folded to provide a place to secure the bottom edge of the structural metal panels. An additional fold is formed at the outermost edges of the valley metal to provide a place to attach clips that will secure the valley metal to the support metal. So water would need to bypass not only the fold that attaches the panels to the valley metal but also the fold used to clip the valley metal to the support metal.

This valley detail is recommended for flat-pan, vertical-seam structural metal panel roof systems with panel slopes from 1/2-in-12 (2.4 degrees) to 2-in-12 (9 degrees).

James R. Kirby, AIA, is an NRCA senior director of technical services.