NRCA participated in an ASTM International interlaboratory study to evaluate the accuracy and precision of the field-uplift test method. The study provides some useful data and information for evaluating the appropriateness and effectiveness of field-uplift testing.

Field-uplift testing

There are two recognized field test methods for determining adhered membrane roof systems’ uplift resistances: ASTM E907, “Standard Test Method for Field Testing Uplift Resistance of Adhered Membrane Roofing Systems,” and FM Global Loss Prevention Data Sheet 1-52 (FM 1-52), “Field Verification of Roof Wind Uplift Resistance.” In each of these test methods, a vacuum is created inside a test chamber mounted on a roof surface and membrane deflections resulting from the induced negative (uplift) pressures inside the chamber are measured.

ASTM E907 has been a consensus-based standard since it was originally published in 1983. ASTM International withdrew the standard in 2013 because it lacked a precision statement, which is required for all ASTM International test methods.

Unlike ASTM E907, FM 1-52 is a nonconsensus based method for performing field-uplift testing on FM Global-insured buildings where the design wind speeds are equal to or greater than 100 mph (hurricane-prone regions) and in tropical cyclone regions. FM 1-52 also lacks any form of precision statement.

ASTM Committee D08 on Roofing and Waterproofing is revising and updating ASTM E907. At the committee’s June meeting, a draft of the standard, including the results of a newly conducted interlaboratory study assessing the test method’s accuracy and precision, was discussed.

The study

An ASTM International interlaboratory study is a procedure used to obtain a test method’s precision statement. It involves multiple laboratories, each generating replicate test results on one or more materials. ASTM E691, “Standard Practice for Conducting an Interlaboratory Study to Determine the Precision of a Test Method,” describes the techniques for planning, conducting, analyzing and treating the results of a test method’s interlaboratory study. ASTM International’s staff assists in planning a study and analyzing test results.

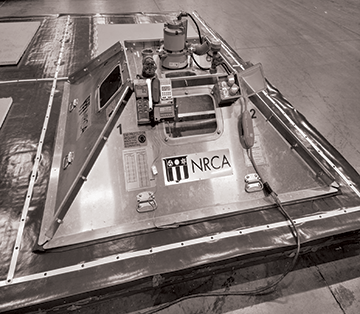

For the interlaboratory study on the field-uplift test method, eight organizations, including NRCA, volunteered to conduct field-uplift tests using similar test equipment under controlled laboratory conditions on a specific roof assembly configuration selected by the ASTM International task force. Replicate roof assembly specimens were constructed and tested at FM Approvals’ West Glocester, R.I., research facility.

The roof assembly configuration selected for the study was a self-adhering, reinforced single-ply membrane over 2-inch-thick polyisocyanurate insulation mechanically fastened to a steel roof deck. Each 4- by 4-foot insulation board was fastened with four fasteners. The tested roof assembly has an FM Approvals’ RoofNav number indicating a Class 90 wind-resistance rating, meaning it had been evaluated by FM Approvals to achieve 90-pounds-per-square-foot uplift resistance.

The specific roof assembly configuration and installation method and test chamber placement on the specimens were specifically selected by the ASTM International task force to limit potential variability in materials, installation and chamber placement. In the study, these variables are intended to be as constant and consistent as possible so the variability in the test method itself—and not the roof assembly—can be analyzed.

Using the then-current draft of the ASTM International field-uplift test procedure, each of the eight organizations conducted three identical tests in 15-psf increments up to the 90-psf classified uplift rating. The resulting roof assembly deflections during testing were measured and recorded at each increment of each test. Twenty-four specimens of the replicate roof assembly were tested at six pressure increments.

The results

The test results show notable variations among testing entities and variations among individual specimens’ results from several of the entities.

ASTM International staff identified some individual results as statistical outliers at the initial 15-psf test increment and continuing at the 30-, 45-, 60- and 90-psf test increments. Some individual results at 30, 45 and 90 psf were considered statistical outliers to the extent these results were excluded from the analysis by ASTM International staff.

Also, 16 of the 24 specimens exhibited failure before completing the 90-psf test increment.

Using FM 1-52’s acceptance criteria, which provides for a maximum allowable deflection of half of an inch for this particular assembly configuration, five of the tests’ results at the 45-psf increment and all the tests’ results at 60, 75 and 90 psf exceeded FM 1-52’s maximum allowable deflection.

My thoughts

I applaud ASTM International and the other participants for conducting the study, as well as FM Approvals for making its facility and staff available. This volunteer effort is no small task and is commendable.

The study’s findings provide useful data and information for evaluating the appropriateness and effectiveness of the field-uplift test method whether that be the withdrawn version of ASTM E907; its newly developed, revised and updated draft version; or FM 1-52.

The variability in deflection values derived under controlled laboratory conditions is of concern. Also, because the study intentionally did not consider other known variables, such as test chamber placement relative to fastener placement, insulation board joint locations and deck supports, and operator and other witness movement, the measured variability shown in the data is only a portion of what is likely in field testing.

Having 16 of the 24 specimens fail without completing the 90-psf test increment necessary to achieve FM Approvals’ Class 90 wind-resistance rating is of notable concern. Clearly, there is no correlation between the field-uplift test method’s results—even under controlled laboratory conditions—and FM Approvals’ laboratory-derived evaluation uplift-resistance classifications.

Also, having all the specimens fail to withstand FM 1-52’s maximum allowable deflection criteria is a significant, further indication of the lack of correlation between FM 1-52’s results and FM Approvals’ uplift-resistance classification.

The ASTM International interlaboratory study clearly illustrates NRCA’s long-standing position that field-uplift testing should not be relied upon as an indicator of an adhered roof assembly’s in situ uplift resistance or as a quality-assurance measure of roof assembly installation. Continuing to use it as such is irresponsible.

Since the study results were released, NRCA’s Technical Operations Committee has asked FM Global to immediately discontinue use of FM 1-52’s field-uplift test as a quality-assurance measure for roof assembly installation.

MARK S. GRAHAM is NRCA’s vice president of technical services.

@MarkGrahamNRCA