When you look at Boston University’s Center for Computing and Data Sciences, you’ll notice its unusual design in the shape of a stack of books. But the building has another remarkable feature: It is the largest fossil-fuel-free building in Boston.

Built in 2022 and designed by KPMP Architects, Toronto, the building’s HVAC system uses closed-loop geothermal wells to draw heat from the ground during winter and expel heat during summer. Only sealants and finishes with few or no volatile organic compounds were used during construction to improve interior air quality.

Other energy-efficient features include triple-glazed windows for better thermal and sound transmission performance, as well as exterior shades to mitigate solar heat gain throughout the day while reducing glare on computer screens and whiteboards. Natural light seeps into the building through staircases meant to reduce electricity consumed by elevators and promote physical activity. On-site dining facilities also use electricity, instead of gas, for cooking.

Given its proximity to Charles River, rising water and sudden storm surges were taken into consideration during the design phase. The building is set 3 feet above the elevation of the Charles River dam and 5 feet higher than the city of Boston’s suggested guidelines for sea-level rise.

A multilevel vegetative roof system absorbs rainwater, reduces stormwater run-off and helps insulate the building. Greenwood Industries Inc., Worcester, Mass., was selected by the project’s general contractor, Suffolk Construction Co., Boston, to install multiple Hydrotech® Garden Roofs and a Sarnafil® G 410-60 EnergySmart 60-mil-thick PVC thermoplastic membrane roof system on the new building.

Vegetative roofs

The building’s stack-of-books look is created by multiple overhanging balconies, each housing a vegetative roof. Several of the balconies have a roof above them, so the Greenwood Industries team could not use a crane to load materials to those areas.

“For the roof areas on floors 11 through 17, we transported roofing materials through the building,” says Mark McKernan, project manager for Greenwood Industries. “As we worked our way to the 18th and 19th floors, we used interior elevators and loaded materials off hours, requiring second-shift labor commitments as we needed to work around other subcontractors.

“As we neared the end of the project, we secured an enormous 400-foot crane that occupied two city blocks and required coordinated street closures,” McKernan continues. “We spent two days setting it up, one day loading materials to the top level and then another two days breaking it down all for one day of work.”

To install 32,000 square feet of Hydrotech Garden Roofs, team members hot fluid-applied Monolithic Membrane 6125® in thicknesses of 90 and 125 mils reinforced with Flex-Flash F spunbonded polyester fabric capped with Hydrocap 90FR, a rubberized asphalt protection sheet, and loosely laid Root Stop HD to receive vegetative overburden. For the pavers, a layer of Hydrodrain® AL filter fabric was placed on the substrate followed by concrete-faced HeavyGUARD® roof insulation panels.

A strict project timeline required the vegetative roofs to be installed during winter, so team members had to carefully dry each section for proper adhesion of the waterproofing membrane.

“This process sometimes took hours, reflecting the team’s dedication to getting the job done right,” McKernan says.

While working on the lower vegetative roof areas, Greenwood Industries workers were tied-off, and a full-time safety officer helped managed the on-site crew.

Membrane roof

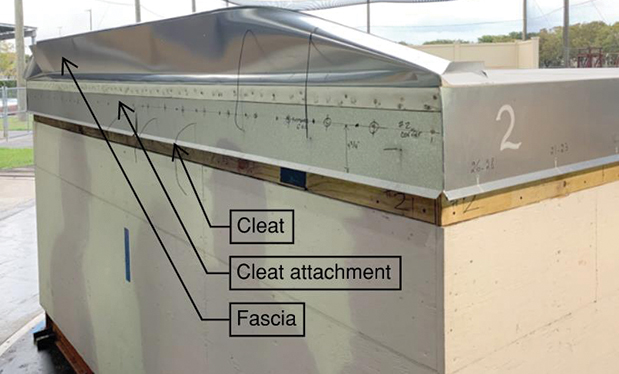

For the 11,000-square-foot membrane roof areas on the 20th and 21st floors, the team primed the roof substrate with Sika® SA Primer and applied self-adhering Sarnafil® Vapor Retarder SA 31. To insulate the system, crew members laid a combination of 4- by 4-foot Sarnatherm® ISO boards in thicknesses of 2 inches and 2 1/2 inches and Sarnatherm ISO tapered boards adhered with Sarnacol® AD Board Adhesive. To complete the system, the team installed an electric field vector mapping grid and adhered the 60-mil-thick Sarnafil G 410-60 EnergySmart PVC thermoplastic membrane.

The crew installed safety rails and parapet clamps to work on the membrane roof and coordinated with Suffolk Construction to ensure all safety standards were followed.

A novel ending

Although the Greenwood Industries team faced logistical and weather issues, the crew completed the project on time and without incident. Thanks to dedicated workers, Boston University’s Center for Computing and Data Sciences will provide sustainable benefits for the community for years to come.

“Because of its shape and multiple levels, Greenwood Industries faced many challenges from finding ways to load and transport materials through the facility up to the roof to completing the project during inclement weather,” says Emma Houston, director of marketing and corporate communication for Sika Roofing, a division of Sika Corp., Lyndhurst, N.J.

“Greenwood Industries’ roof system and paver installations on Boston University’s Center for Computing and Data Sciences allowed us to be part of one of the most sustainable and energy-efficient buildings in Boston,” adds Ginny Pitcher, director of marketing and corporate communications for Greenwood Industries. “We are honored to have worked on the unique project.”

PROJECT NAME: Boston University’s Center for Computing and Data Sciences

PROJECT LOCATION: Boston

PROJECT DURATION: October 2021-May 2023

ROOFING CONTRACTOR: Greenwood Industries Inc., Worcester, Mass.

ROOF SYSTEM TYPE: Hot liquid-applied rubberized asphalt waterproofing system with vegetative and insulated paver overburden and PVC thermoplastic roof membrane

ROOFING MANUFACTURERS: American Hydrotech® Inc., a Sika company, Chicago; Clear Corp., Hamilton, Ohio; Sika Corp., Lyndhurst, N.J.

CHRYSTINE ELLE HANUS is Professional Roofing’s associate editor and an NRCA director of communications.