Built on the site of an old elevator factory overlooking the Hudson River, Lionsgate Studios, Yonkers, N.Y., opened in January 2022 with plans of becoming the largest modern-built film and television production facility in the Northeast.

Owned by Great Point Studios, whose movie portfolio includes popular franchises such as “The Hunger Games,” “John Wick” and the “Twilight” saga, the $500 million studio campus features two 20,000-square-foot sound stages, a smaller 10,000-square-foot stage, six talent suites for actors, dozens of dressing rooms, hair and makeup stations, dedicated writers’ rooms, a carpentry shop for set construction and office space.

During the summer of 2021, design/build firm Steve Pustola and Associates, Naugatuck, Conn., contacted Nations Roof—East, Yonkers, N.Y., to install a roof system on one of the studio’s sound stages. The project successfully was completed using a double layer of polyisocyanurate insulation and 60-mil-thick mechanically attached TPO membrane.

A few months later, the developer contacted Nations Roof again to install a new roof system on another sound stage. But this time, the new roof would be much more complex and unlike anything the company previously installed.

Collaboration

After Nations Roof installed the first roof system, television crews working in the building realized the more than 100 commuter trains passing nearby daily produced so much noise, filming had to stop every time a train went by. Great Point Studios asked the Nations Roof team to develop a solution to block out the noise pollution before installing a roof system on a new building.

The team brought in several partners to design a roof system that addresses three fundamentals to reducing sound transmission through a roof assembly: adding mass, adding absorption and decoupling.

“Although we were familiar with a number of roofing products that had sound blocking properties, we looked to several manufacturers to help us dig into the product specifications and come up with a fully warrantable system that also met the acoustical needs of the building owner,” says Michael Johannes, president of Nations Roof—East.

The Nations Roof team called in ROCKWOOL,® Milton, Ontario, for help with increasing the sound transmission class rating. The ROCKWOOL building science team used the results from its highest-performing assembly to model a further improved roof assembly. The analysis predicted an STC rating of 55, a robust rating that met the client’s demanding requirements. The team also evaluated the thermal performance of the roof system and estimated an R-value of 38, exceeding the minimum requirement of 30.

To provide mass, the ROCKWOOL team recommended Georgia-Pacific DensDeck® Roof Boards. For sound absorption, ROCKWOOL Toprock® B-Deck Flute Filler and Toprock DD insulation were recommended. The manufacturing team also recommended adhering the top layer of DensDeck Prime Roof Boards and the roof membrane to decouple them from the fasteners and layers below.

Once the acoustical design was accepted by Great Point Studios, the Nations Roof team brought the assembly to Carlisle® SynTec Systems, Carlisle, Pa., to ensure it met warranty requirements. The Carlisle SynTec Systems team recommended 80-mil-thick Sure-Weld® Extra TPO for the membrane and offered the client a 20-year system warranty.

The roof assembly

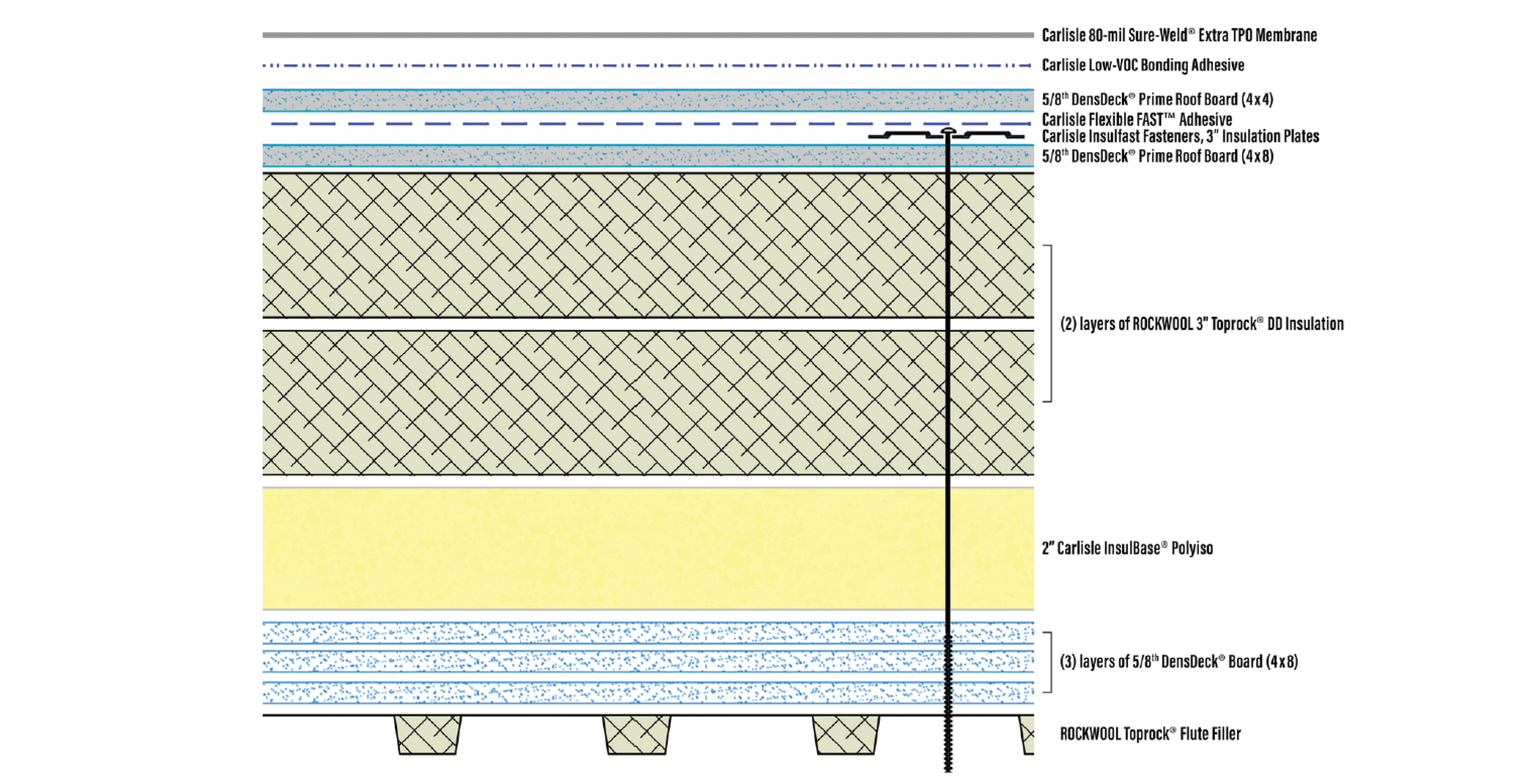

The final roof system (not including the steel deck) measures more than 11 1/4 inches deep.

“It was a little bit daunting to say the least when we saw everything it was going to take to be able to control sound in addition to being able to control water getting into the system,” Johannes says.

In February 2023, the Nations Roof crew began the task of installing the following roofing materials on top of the roof deck (see figure):

- ROCKWOOL Toprock B-Deck Flute Filler

- Three layers of 5/8-inch-thick, 4- by 8-foot Georgia-Pacific DensDeck Roof Boards

- One layer of 2-inch-thick Carlisle InsulBase™ polyisocyanurate insulation

- Two layers of 3-inch-thick ROCKWOOL Toprock DD insulation

- One layer of 5/8-inch-thick, 4- by 8-foot Georgia-Pacific DensDeck Prime Roof Boards

- Carlisle Insulfast™ Fasteners with 3-inch Insulation Plates

- Carlisle Flexible FAST™ Adhesive

- One layer of 5/8-inch-thick, 4- by 4-foot Georgia-Pacific DensDeck Prime Roof Boards

- Carlisle Low-VOC Bonding Adhesive

- One layer of Carlisle 80-mil-thick Sure-Weld Extra TPO Membrane in gray

Nations Roof also partnered with Beacon Building Products, Herndon, Va., local distributor for Carlisle SynTec Systems.

“On a complex system like this, it’s challenging to have everything show up on time and in the proper sequence so the roofing team can load the roof properly and meet the production schedule work without delay,” Johannes says. “Beacon Building Products coordinated the delivery of 16 truckloads of materials and did an excellent job of coordinating deliveries and lifting materials to the rooftop.”

Safety

Adding to the project’s complexity, Lionsgate Studios is located on a busy urban street.

“The safety of our crews is paramount, and safety was the first component that went into this project even before materials were ordered,” says Arios Geci, Lionsgate Studios project manager for Nations Roof. “This project required a unique plan to accommodate the loading of a large amount of materials required for the roof assembly.”

The Nations Roof team created a site-specific safety plan that included a safety railing and orange netting on all sides of the building, barriers to separate workers from street traffic, daily on-site safety “huddles” and posted safety information with emergency contacts. As a result of diligent safety measures, the crew worked more than 2,800 man-hours on the project without incident.

“The project presented unique safety challenges to the crew on-site,” Johannes says. “We were confident in our planning and preparation to address any issues before they resulted in an incident. We fulfilled our goal to keep our team safe and able to go home to family and loved ones at the end of each workday.”

Quiet on set

In May 2023, the Nations Roof team completed a substantial amount of the roofing work on Lionsgate Studios with final details finished in August 2023. Thanks to a mobilized team of partners who each contributed unique expertise to solving Great Point Studios’ sound dilemma, the team successfully delivered a strong, durable, soundproof roof system while protecting the building envelope.

“Our crew was able to draw on experience installing all the individual components to complete an innovative assembly,” Johannes says. “When you watch a Lionsgate film recorded in Yonkers, you’ll only hear the sounds that were meant to be heard inside the studio thanks to the roof system.”

For its work on Lionsgate Studios, Nations Roof—East received a 2024 NRCA Gold Circle Award in the Innovative Solutions category.

PROJECT NAME: Lionsgate Studios

PROJECT LOCATION: Yonkers, N.Y.

PROJECT DURATION: February-August 2023

ROOFING CONTRACTOR: Nations Roof—East, Yonkers, N.Y.

ROOF SYSTEM TYPE: TPO membrane

ROOFING MANUFACTURERS: Carlisle® SynTec Systems, Carlisle, Pa.; Georgia-Pacific Gypsum, Atlanta; ROCKWOOL,® Milton, Ontario

CHRYSTINE ELLE HANUS is Professional Roofing’s associate editor and an NRCA director of communications.