NRCA has conducted limited R-value testing of polystyrene insulation products used as roof system components. The polystyrene insulation was tested to determine whether the tested values meet ASTM International's recognized values.

According to the U.S. product standard for polystyrene insulation, ASTM C578, "Standard Specification for Rigid, Cellular Polystyrene Thermal Insulation," 15 types of polystyrene insulation are manufactured in the U.S. ASTM C578, Type VIII, designates 1.25 pounds per cubic foot nominal density expanded polystyrene (EPS) insulation typically used in roof system installation. ASTM C578, Type IV, designates 25 pounds per square inch compressive strength extruded polystyrene (XPS) insulation typically used in below-membrane roofing applications.

NRCA testing

NRCA obtained multiple samples of new (uninstalled) 2-inch-thick EPS and XPS insulation from various manufacturers. The samples were provided to R&D Services Inc., Cookville, Tenn., for R-value testing conducted according to ASTM C518, "Standard Test Method for Steady-State Thermal Transmission Properties by Means of the Heat Flow Meter Apparatus." The samples' R-values were tested without additional aging. The samples ranged from three to eight months old.

NRCA's tested R-value data

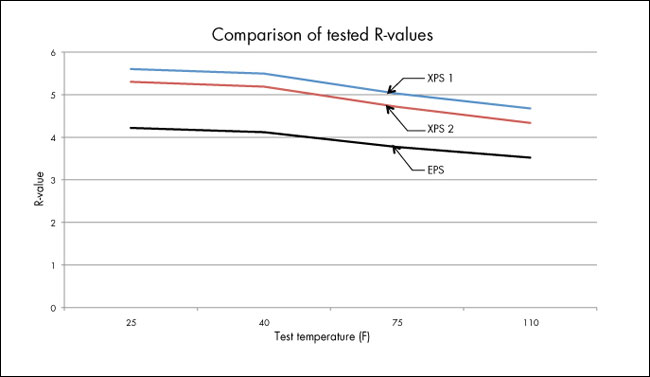

R-values were tested at a 75 F mean reference temperature, as well as 25 F, 40 F and 110 F. The 75 F reference temperature is used to determine compliance with ASTM C578, as well as for product comparisons. NRCA considers R-value testing at the other temperatures to be useful because they better represent actual in-service conditions.

A graph of tested R-values is provided in the figure.

Analyzing results

For compliance, ASTM C578 requires a minimum R-value of 3.8 per inch thickness for Type VIII (EPS) and 5 per inch thickness for Type IV (XPS) tested at 75 F.

The EPS sample NRCA tested had an R-value of 3.771 per inch thickness at 75 F. This test value is slightly lower than the minimum requirement in ASTM C578; however, the difference is within the range of the test method's allowed precision.

Regarding the XPS samples, a sample from one manufacturer exceeded the ASTM C578 minimum requirement with a tested R-value of 5.025 at 75 F. However, a sample from another manufacturer was noticeably lower than the ASTM C578 requirement with a tested R-value of 4.677 at 75 F.

The R-values tested at the 25 F, 40 F and 110 F test temperatures tracked largely as expected. Polystyrene is recognized to have slightly higher R-values at test temperatures lower than 75 F and slightly lower R-values at test temperatures higher than 75 F.

What to do?

NRCA urges polystyrene insulation users to consult with polystyrene insulation manufacturers about their specific recommendations regarding R-values.

For additional information about EPS and XPS insulations used in roof systems, see The NRCA Roofing Manual: Membrane Roof Systems—2011, Chapter 3—Rigid Board Insulation, pages 49-55.

Mark S. Graham is NRCA's associate executive director of technical services.