In “An evolution of knowledge,” February 2022 issue, I discussed NRCA’s research examining roofing-related problems with moisture in concrete roof decks. One area where NRCA considered additional research to be necessary was addressing the adequacy of vapor retarder adhesion to newly placed concrete roof decks.

NRCA has since undertaken this research, which provides designers with some guidance for proper vapor retarder selection.

Adhesion research

NRCA contracted with SRI Consultants Inc., Waunakee, Wis., to oversee test specimen preparation and conduct vapor retarder adhesion testing.

Ten 6-inch-thick concrete roof deck specimen sets were poured using normal-weight structural concrete. The top surfaces of the concrete specimens were float-finished.

After 28 days of curing at standard laboratory conditions, a two-ply built-up membrane was applied to two of the concrete roof deck specimens and four different manufacturers’ self-adhering vapor retarder products were applied to the remaining concrete roof deck specimens in two specimens sets. For each of the self-adhering vapor retarder types, the manufacturer’s recommended primer was used, and installations were done in accordance with manufacturers’ installation instructions by an experienced roofing contractor.

One set of each of the concrete roof deck and vapor retarder specimens were conditioned at standard laboratory conditions for 60 days. For the remaining concrete deck and vapor retarder sets, insulated enclosures were constructed on the bottoms of the specimens and heat was applied, resulting in a 30-degree Fahrenheit temperature differential across the bottom to the top of the specimens. This temperature differential created a net vapor pressure drive from the bottoms to the tops of the specimens. This same net vapor pressure assessment concept also was used in NRCA’s earlier research.

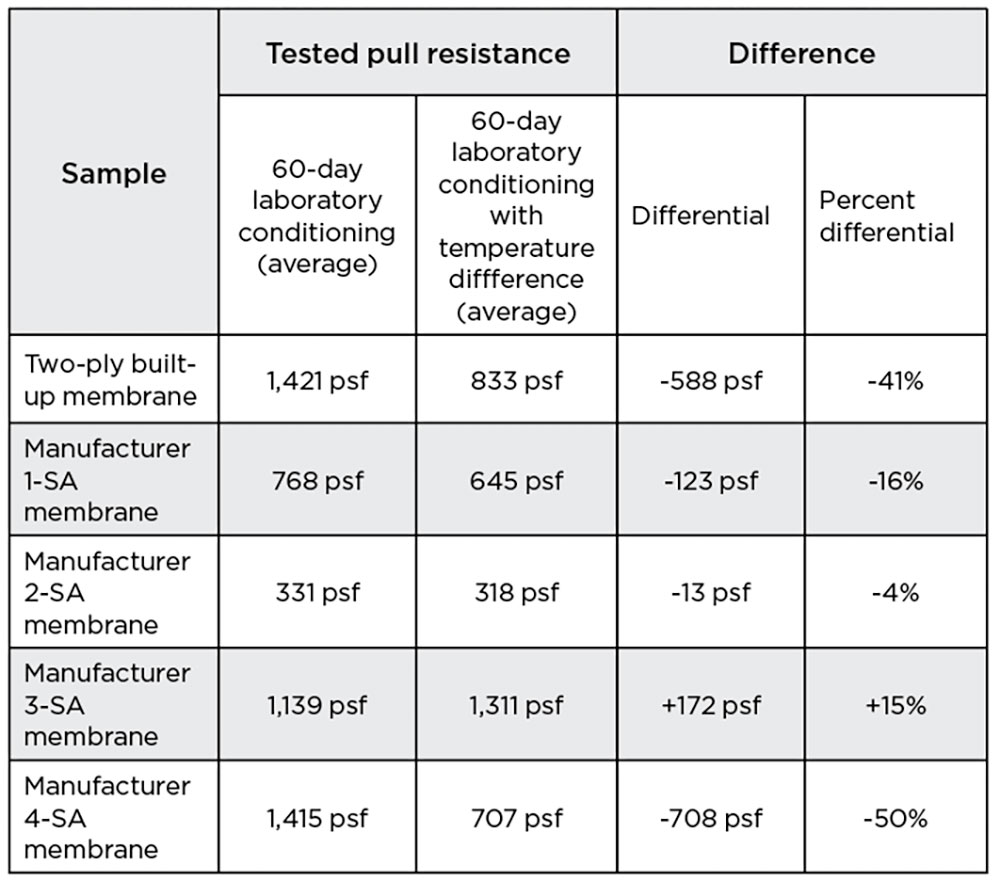

After 60 days of conditioning, the vapor retarder specimens were cut to size, a load frame was applied and a calibrated pull tester was used to test the adhesion of the vapor retarders to the concrete roof deck specimens. Five specimens of each vapor retarder type and condition were tested. The average of the five specimens’ results are shown in the figure.

The testing shows adhesion of vapor retarders to concrete decks varies widely. For four of the five vapor retarders, the results of the temperature differential-conditioned samples were lower than the laboratory-conditioned samples. For sample manufacturer 3-SA membrane, the temperature differential-conditioned test specimens tested higher than the specimens that had been laboratory-conditioned.

I consider the two-ply built-up roof membrane samples to be somewhat baseline control samples. Historically, the U.S. roofing industry has successfully used two-ply BUR membranes as adhered vapor retarders over concrete roof decks. In the laboratory-conditioned testing, the two-ply BUR membrane sample exhibited greater adhesion than the self-adhering vapor retarder samples. Only sample manufacturer 3-SA membrane exhibited greater adhesion than the two-ply BUR membrane samples after temperature differential conditioning.

It should be noted all samples exhibited adhesion well in excess of what is necessary to achieve Class 90 (FM 1-90) uplift.Recommendations

Because adhesion of vapor retarders to concrete decks varies, designers should specify vapor retarders after considering vapor retarder adhesion at the time of application and while in service.

Also, manufacturers should incorporate some form of vapor drive conditioning assessment in their product developments and assessments and make that information available to specifiers. The vapor drive conditioning used in this testing is one possible assessment method.

NRCA continues to recommend roof system designers use caution when specifying the installation of membrane roof systems over newly poured normal-weight and lightweight structural concrete roof decks. When adequate dryness of concrete roof decks cannot be reasonably ensured, NRCA recommends a well-adhered, low-perm-rated vapor retarder be specified for installation directly over the concrete roof deck. Then, an adhered or loosely laid ballasted roof system can be specified over the vapor retarder, preferably installed the same day or within several days of vapor retarder installation.

Roof system types that involve mechanical fasteners that would penetrate the vapor retarder should be avoided to ensure vapor retarder performance. The purpose of the vapor retarder is to isolate a concrete deck’s free water within the concrete and minimize the potential for moisture vapor transport into the roof system.

NRCA also maintains its long-standing recommendation that the use of curing and finishing compounds be avoided when placing and finishing structural concrete roof decks as these compounds are known to retard moisture release and can affect adhesion of roofing materials.

In addition, NRCA suggests roof system designers minimize the use of materials and products with organic content over concrete roof decks to decrease the potential for microbial growth in the event moisture from a concrete roof deck infiltrates the roof system. Examples of roofing products with organic content include fiberglass-reinforced, cellulosic mat-faced polyisocyanurate; perlite board; and wood fiberboard. Coated, fiberglass mat-faced polyisocyanurate insulation is preferred over fiberglass-reinforced, cellulosic mat-faced polyisocyanurate in concrete roof deck applications.

For reroofing situations over existing concrete roof decks where there is evidence of concrete deck-related moisture problems, NRCA suggests roof system designs similar to those recommended for newly placed concrete roof decks.

Additional information about moisture migration in roof assemblies is provided in the Condensation and Air Leakage Control section of The NRCA Roofing Manual: Architectural Metal Flashing and Condensation and Air Leakage Control. Additional information about concrete roof decks and vapor retarders is provided in Chapter 2—Roof Decks and Chapter 3—Air and Vapor Retarders, respectively, of The NRCA Roofing Manual: Membrane Roof Systems.

NRCA members can download both manuals free from shop.nrca.net. Hard copies also are available to purchase.

MARK S. GRAHAM is NRCA’s vice president of technical services.

@MarkGrahamNRCA

This column is part of Research + Tech. Click here to read additional stories from this section.