Faced rigid board polyisocyanurate insulation is the most common type of thermal insulation used in the U.S. roofing industry; as such, the proper specification of polyisocyanurate insulation is an important consideration for successfully performing roof systems. Following are some considerations and NRCA’s recommended guidelines for specifying polyisocyanurate insulation.

Considerations

The U.S. product standard for polyisocyanurate insulation is ASTM C1289, “Standard Specification for Faced Rigid Cellular Polyisocyanurate Thermal Insulation Board.” ASTM C1289 addresses 18 compositions of polyisocyanurate insulation by using specific types, classes and grades. Type and class designations generally define specific facers, and grade classifications indicate the minimum compressive strength of the polyisocyanurate foam. For example, polyisocyanurate insulation with reinforced, cellulosic mat facers that has a minimum 20-psi compressive strength is designated as ASTM C1289, Type II, Class 1, Grade 2.

Polyisocyanurate insulation is commonly available in 4- by 4-foot and 4- by 8-foot board sizes. 4- by 4-foot boards generally are used when the boards are adhered or serve as a substrate for adhered membrane applications. 4- by 8-foot boards generally are used for loosely laid and mechanically attached membrane systems. Manufacturers’ specific UL and FM Approvals certifications typically designate specific board size requirements.

Polyisocyanurate thermal insulation is available in thicknesses ranging from 1 to about 4 inches in 0.1-inch increments. Tapered polyisocyanurate insulation also is available. High-density polyisocyanurate cover boards typically are available in 1/4-, 3/8- and 1/2-inch thicknesses.

Polyisocyanurate insulation’s thermal resistance (R-value) correlates to its thickness. Polyisocyanurate insulation manufacturers generally use the long-term thermal resistance method for reporting R-values in product literature and markings. Minimum LTTR values typically are 5.6 per inch thickness for 1-inch-thick products, 5.7 per inch thickness for 2-inch-thick products, 5.8 per inch thickness for 3-inch-thick products and 5.9 per inch thickness for 4-inch-thick products.

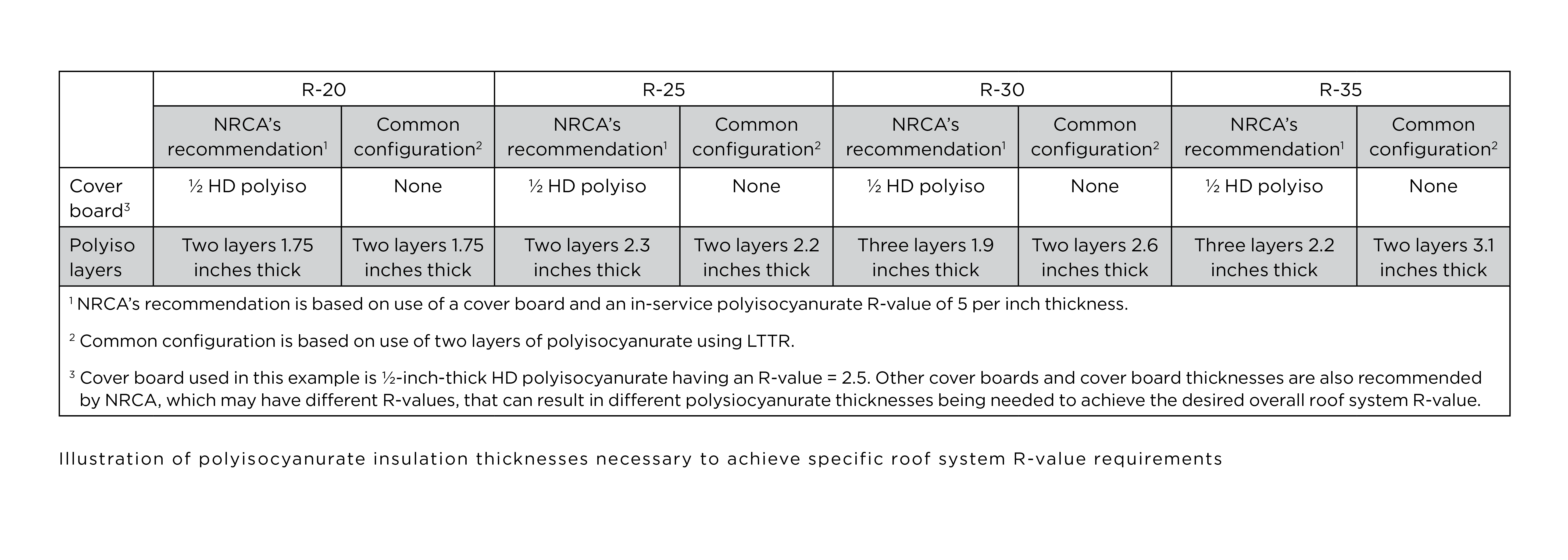

Instead of using the LTTR method, NRCA recommends designers specifying polyisocyanurate insulation determine insulation R-value using an in-service R-value of 5 per inch thickness of polyisocyanurate insulation. This reduced R-value (from LTTR) accounts for known losses in polyisocyanurate insulation’s R-value over time and in changing temperature conditions.

NRCA recommends polyisocyanurate insulation be installed in multilayer applications, especially when the total thickness of polyisocyanurate insulation is more than 2 1/2 inches. NRCA’s maximum 2 1/2-inch-thick recommendation is based on dimensional stability and facer sheet delamination concerns.

NRCA also recommends designers specify a suitable cover board over polyisocyanurate insulation for all low-slope membrane roof systems.

The figure compares polyisocyanurate insulation thicknesses necessary to achieve specific roof system configuration and R-value requirements.

Specifications

NRCA recommends designers specify polyisocyanurate insulation using the ASTM C1289 designation followed by the specific type classification and, if applicable, class and grade classifications necessary to identify the intended products’ compressive strength and facers.

NRCA recognizes some designers will choose not to use NRCA’s best practice in-service R-value, maximum board thickness and cover board recommendations. Although specifying polyisocyanurate insulation based on its LTTR, using manufacturers’ available thicknesses and, sometimes, omitting cover boards are not consistent with NRCA’s best practice guidelines, these should not be considered as unacceptable.

To avoid possible confusion, NRCA recommends polyisocyanurate insulation be specified based on its thickness and not its LTTR or R-value. Board size also should be specified.

Additional information regarding the use of polyisocyanurate insulation in membrane roof systems is provided in The NRCA Roofing Manual: Membrane Roof Systems—2019’s Chapter 4—Rigid Board Insulation, Section 4.9—Polyisocyanurate Insulation.

Mark S. Graham is NRCA's vice president of technical services.

@MarkGrahamNRCA

For articles related to this topic, see the Tech Today columns in the March 2013 and August 2013 issues.

This column is part of Research + Tech. Click here to read additional stories from this section.