In late 2014, NRCA conducted limited R-value testing of polyisocyanurate insulation products. The test results show R-values lower than the product manufacturers' published long-term thermal resistance (LTTR) values.

2014 testing

NRCA obtained seven samples of newly manufactured (uninstalled) 2-inch-thick, permeable-facer-sheet-faced polyisocyanurate insulation made by six U.S. manufacturers. The samples were obtained from NRCA contractor members throughout the U.S.

The samples were provided to a nationally recognized R-value testing laboratory, R & D Services Inc., Cookeville, Tenn., for R-value testing according to ASTM C518, "Standard Test Method for Steady-State Thermal Resistance Properties by Means of the Heat Flow Meter Apparatus." The samples were tested "as received," meaning without additional aging. The samples ranged in age from three months to 19 months at the time of testing.

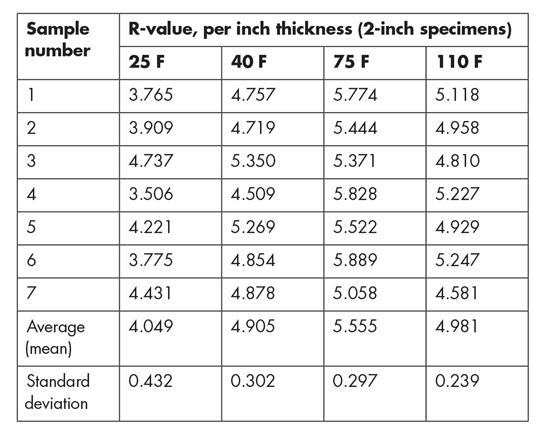

Data from NRCA's 2014 polyisocyanurate R-value testing

R-values were tested at a 75 F mean reference temperature, as well as at 25 F, 40 F and 110 F. Although R-values tested at the 75 F mean reference temperature typically are reported in insulation product manufacturers' literature, NRCA views the additional test temperatures as being more representative of actual in-service conditions.

Data from this testing is provided in the figure.

Analysis

Review of the 75 F data reveals the average of the results are less than the products' published LTTR values. Only three of the seven specimens have R-values greater than 5.7 per inch for a 2-inch-thickness.

The LTTR concept is intended to replicate a 15-year time-weighted average of a product's R-value, which corresponds to a product's R-value after five years of aging. Because none of the products tested were even close to 5 years old at the time of testing, all their tested R-values at 75 F should be somewhat above their published LTTR values.

In 2009, NRCA conducted similar R-value testing of polyisocyanurate insulation samples, and the results were much the same.

Review of the current test data at 25 F, 40 F and 110 F shows tested R-values are notably lower than those tested at 75 F.

Comparing current test data with the 2009 test data reveals the current test values are somewhat lower. For example, the average of the current 25 F R-values is 4.049 compared with 4.744 in 2009. At 40 F, the average of the current R-values is 4.905 compared with 5.39 in 2009.

NRCA's recommendations

Although the 75 F mean test temperature may be useful for product comparison and labeling purposes, based on NRCA's testing, it is clear this parameter is not representative of in-service conditions. For this reason, NRCA recommends designers consider polyisocyanurate insulation products' in-service R-values for the specific climate where a building is located.

NRCA recommends designers using polyisocyanurate insulation determine thermal insulation requirements using an in-service R-value of 5.0 per inch thickness in heating conditions and 5.6 per inch thickness in cooling conditions.

Furthermore, NRCA recommends designers specify polyisocyanurate insulation by its desired thickness rather than its R-value or LTTR value to avoid possible confusion during procurement.

Additional information regarding the use of polyisocyanurate insulation is provided in The NRCA Roofing Manual: Membrane Roof Systems—2015.

Mark S. Graham is NRCA's associate executive director of technical services.

For an article related to this topic, see: "R-value concerns," May 2010 issue, page 24