NRCA has conducted limited R-value testing of high R-value rigid board insulation. The tests' results show R-values lower than the products' published long-term thermal resistance (LTTR) values. If you design roof systems using high R-value rigid board insulation, you should be aware of this data.

NRCA testing

NRCA obtained 15 samples of new (uninstalled) 2-inch-thick, felt-faced polyisocyanurate insulation from NRCA contractor members throughout the U.S.

The samples were provided to R & D Services Inc., Cookeville, Tenn., for R-value testing conducted according to ASTM C518, "Standard Test Method for Steady-State Thermal Transmission Properties by Means of the Heat Flow Meter Apparatus." The samples' R-values were tested as received, meaning without any additional aging. The samples ranged in age from four to 13 months.

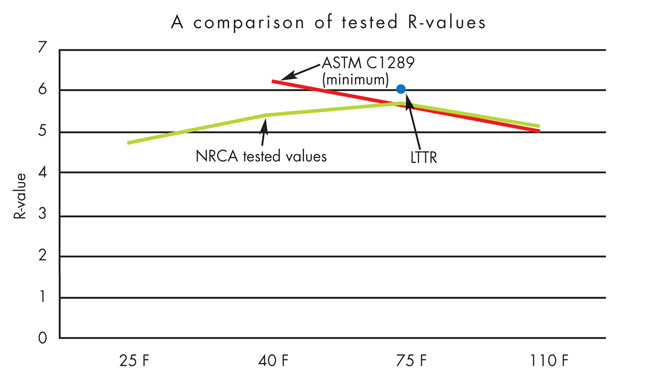

R-values were tested at a 75 F mean reference temperature, as well as at 25 F, 40 F and 110 F. NRCA views these additional test temperatures as being more representative of actual in-service conditions than the 75 F reference temperature typically used for product comparison and labeling.

A graph of mean tested R-values is provided in the figure.

Comparing R-values

LTTR is intended to represent the R-values of specimens tested after five years of aging when stored in a controlled laboratory environment. This five-year figure corresponds closely to a predicted 15-year, time-weighted average of R-values.

NRCA's tested data, LTTR and ASTM C1289's minimum required R-values

ASTM C518—the same test method used in NRCA's testing—is the preferred test method for determining specimen R-values in the LTTR methodology. However, in the LTTR methodology, the foam material's thickness is reduced (sliced and scaled) to accelerate aging before testing. (For additional information, see "Testing LTTR," January 2006 issue, page 30.)

Review of NRCA's test results reveals tested R-values lower than the predicted five-year-old value in laboratory conditions (LTTR = 6.0). Also, NRCA's tested values are somewhat lower than those of ASTM C1289, "Standard Specification for Faced Rigid Cellular Polyisocyanurate Thermal Insulation Board," at 40 F.

What to do?

NRCA maintains its longstanding recommendation that designers determine polyisocyanurate board insulation's total inservice thermal resistance on the basis of an R-value of 5.6 per inch.

However, based on NRCA's testing, it may be prudent for designers to use an even lower R-value when designing for cold conditions, such as in northern climates or cold-storage applications.

Mark S. Graham is NRCA's associate executive director of technical services.