This month, the NRCA Repair Manual for Low-slope Membrane Roof Systems, Second Edition will be published. The new manual updates and replaces the ARMA/NRCA/SPRI Repair Manual for Low-slope Membrane Roof Systems published in 1997.

The repair manual is an unbiased, authoritative reference guide of industry best practices for the maintenance and repair of low-slope membrane roof systems, including built-up roofing, polymer-modified bitumen, thermoplastic and thermoset roof membrane systems.

Scope and audience

Repair procedures contained in the manual are based on information collected by NRCA from knowledgeable, practicing roofing contractors located in the U.S. and Canada. The procedures reflect the consensus of the consulted roofing contractors, but the manual is not intended as an exhaustive reference for all practices or applications. Other repairs not noted in the manual, such as repairs based on time-tested area practices, may be acceptable. The procedures in the new manual are intended for the identification and permanent repair of low-slope roof membrane deficiencies.

The manual presents NRCA's best practice recommendations for maintenance and permanent repairs that may be completed by a field crew of roofing workers during a service call to a customer's location. Repairs requiring additional evaluation, design work and/or tools, training, or materials that are unconventional or uncommon for roofing service crews in their geographic areas are outside the manual's scope. In such instances, the manual recommends service crews collect additional information about existing conditions and return it to management. Project-specific designs then may be developed with bids provided to building owners.

Some examples of work outside the manual's scope include roof deck repairs; design, installation and flashing of supports for improperly supported and flashed rooftop mechanical units and connections between dissimilar roof systems; and replacement of missing or damaged roof edge metal.

The manual primarily is intended for professional roofing workers. Knowledge of roofing materials, application techniques and safety practices is essential for successful completion of repairs addressed in the manual. Although the manual also may be used by building maintenance personnel trained in common roof system repair scenarios and roof safety, users should note roof system repair proficiency requires hands-on experience. If building maintenance personnel have little to no experience with needed repairs, it is best to hire professional roofing contractors to perform the work.

Development

NRCA's Repair Manual Task Force developed the manual. The task force was composed of the following experienced roofing contractors who have been active as volunteer members of NRCA committees for many years: Scott Baxter, president of Nations Roof of Oregon LLC, Tualatin; Dane Bradford, president of Bradford Roof Management, Billings, Mont. (Bradford also was involved with developing the 1997 manual); Stephen Teal, manager of Flynn Group of Companies, Rocky View, Alberta; Kyle Thomas, owner and vice president of Thomas Roofing Co. Inc., Mobile, Ala.; and Bob Willis, vice president of Dayton sales, Tecta America Zero Company LLC, Dayton, Ohio.

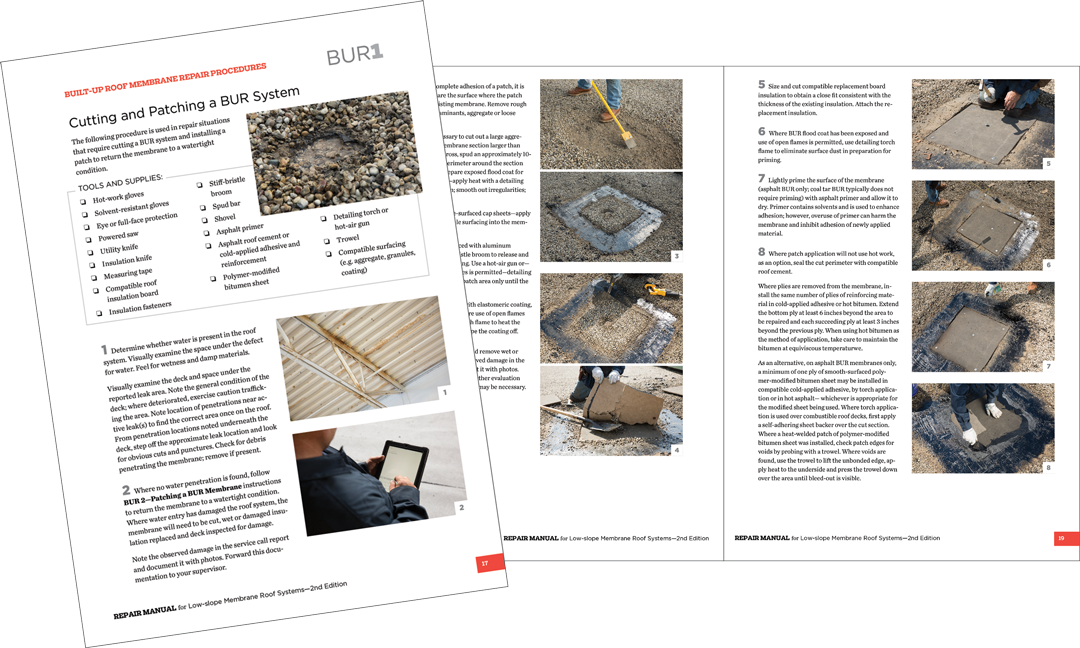

The repair manual's latest edition features step-by-step instructions. |

The task force first met in July 2015 to review its objectives and establish milestones. During the following 18 months, the task force reviewed and updated the 1997 text. Because the original instructions were developed during the 1990s, updating the manual was a considerable undertaking requiring a deliberate, meticulous process. The revisions had to address more than two decades of technological evolution of materials and methods used for low-slope roof membrane application and maintenance. Some current commonly used materials and techniques were not available in the 1990s, so new recommendations had to be developed.

At every in-person task force meeting, NRCA board members were in attendance to ask questions, offer advice and encourage progress. The task force received feedback indicating roofing company service departments frequently use the 1997 manual, and contractors wanted new and updated repair guidelines.

NRCA received critically important assistance from the Chicago Roofers Joint Apprenticeship & Training Program, Indian Head Park, Ill., and Ridgeworth Roofing Co. Inc., Frankfort, Ill. These organizations donated use of their locations, equipment and materials and the help of their skilled staffs for staging the repairs photographed for the manual.

By January 2017, work on the updated procedures text was finished, and the task force turned its attention to developing the photography. A majority of photo content used in the new manual was shot during the summer of 2017. NRCA engaged a professional photographer to produce high-quality images. For a few repair procedures, the task force determined the 1997 photos (in color) provide suitable, accurate depictions. Additional photos also were provided by task force members.

During the fall of 2017, the task force reviewed combined text and photographs and made final recommendations for edits. Illustrations for a few repair procedures were unattainable because suitable conditions could not be located and photographed. However, the task force wished to deliver a much-needed resource in a timely manner, so NRCA proceeded with publishing the manual. Electronic updates will be issued as they become available.

Content

Repair procedures in the manual are organized into sections that specifically address built-up, polymer-modified bitumen, thermoplastic and thermoset roof membranes, as well as mechanically attached metal flashings.

Those who used NRCA's previous repair manual will find the format familiar. Step-by-step repair and maintenance instructions are photo-illustrated in full color (the previous photos were black and white).

There are 90 repair and maintenance procedures in the manual. Each includes a checklist of tools and supplies. Membrane cutting and patching repairs are placed at the beginning of each membrane-specific section—these are the most frequently performed repairs. They are used for membranes that have suffered mechanical damage from impacts, rooftop traffic, dropped tools and/or abuse by other trades.

Next are repairs intended to correct common membrane application deficiencies and maintenance items that ordinarily are observed during roof system inspections or may develop when roof membrane inspections are neglected. Common application deficiencies targeted depend on membrane type. For example, bituminous membrane fishmouths, dry laps, open flashing laps and blisters are addressed. Missing T-joint covers and open laps and splices are addressed for single-ply membranes. Instructions for maintenance items address membrane surfacing erosion, surface contamination, fastener back-out, loose base and wall flashings, membranes bridging over displaced or damaged insulation, and membrane tenting, as well as other conditions.

About two-thirds through the inventory of procedures in each membrane type-specific section are instructions for the most complex—and typically most time-consuming—repairs addressed in the manual. They include repairs for metal edge flashings, installation of penetration pockets, roof drain testing, and installation of new roof drain flashings and liquid-applied flashing applications for penetrations and scuppers. Many of these incorporate steps from less involved repair and maintenance procedures either by reference or verbatim.

Introduction to each membrane type-specific section provides additional guidance regarding common industry work practices and design best practices helpful for repair crews but not addressed at length as part of repair instructions. For example, practices for preparing bituminous membranes for coating are discussed. Also, specific NRCA construction details are recommended for repairs requiring additional design work.

Metal flashings are common maintenance items with all types of membrane roof systems. The final section in the manual addresses maintenance for metal copings, counterflashings, termination bars and expansion joint covers.

Three appendixes contain checklists that may be used to help manage service crews: a checklist of information collected from an incoming call; a checklist of information brought back from a service call; and an inventory of service truck materials and tools.

Put it to work

The NRCA Repair Manual for Low-slope Membrane Roof Systems, Second Edition is a valuable tool for roofing contractors. It may be used to help grow your service department at your business and set it apart from your competition.

In addition to its primary use as a work and training aid for field roofing workers, the manual is a resource to be used when communicating with building owners. For example, when owners raise questions about correct procedures or the scope of work for a specific task, the manual can be referenced as a source of best practice recommendations.

If your company operates service crews—as most roofing contractors do—I encourage you to add the new manual to your technical library.

NRCA intends to periodically update the manual as industry technology evolves, improved practices are developed and opportunities for photoshoots become available. To get your copy, visit NRCA's online bookstore at www.nrca.net/store.