With the proliferation of the sustainability movement within the construction industry, green roofing is touted as one of the ways to make roof systems more environmentally friendly. Recognizing this trend, NRCA began developing a green roofing manual in 2004. And in 2007, NRCA published The NRCA Green Roof Systems Manual—2007 Edition.

The manual provides in-depth information about green roof system projects. The information contained in the manual was developed by NRCA member contractors and applies to roofing contractors, designers, manufacturers, and third-party individuals involved with green roof system design and installation.

Although some information is provided about green roof system components, such as drainage layers, moisture-retention layers and filter fabric, if you use the manual, you primarily will find specific information about selection, design and installation of waterproofing membranes appropriate for green roof systems.

The manual

The manual is divided into four main sections: General Green Roof Project Considerations, Green Roof System Guidelines, Green Roof System Construction Details and Glossary.

Considerations

The General Green Roof Project Considerations section provides an overview of general information concerning the design and installation of quality green roof systems. The information is intended to complement The NRCA Roofing Manual series and should be used as a guideline to prepare proper specifications.

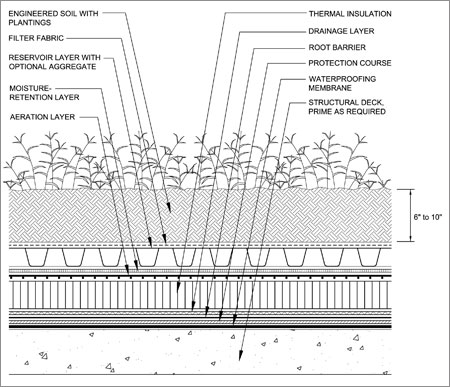

The manual defines a green roof system as "a roof area of plantings/landscaping installed above a waterproofed substrate at any building level that is separated from the ground beneath it by a man-made structure. A green roof system consists of a waterproofing system and its associated components—such as protection course, root barrier, drainage layer, thermal insulation and aeration layer—and an overburden of growth medium and plantings."

As with all roof system types, proper design, quality materials and quality workmanship are needed to achieve a green roof system that will perform satisfactorily for its anticipated service life. Appropriate maintenance during a green roof system's service life also is necessary to ensure its success.

Also provided in the General Green Roof Project Considerations section is information about pre-bid and pre-job conferences; material storage and handling; temporary green roof waterproofing systems; weather considerations (such as high- and low-temperature installation, wind and precipitation); deck and structural design considerations; surface inspection; slope and drainage; expansion joints and control joints; curbs and penetrations; flashings (such as membrane base flashings, sheet-metal counterflashings and terminations); quality assurance and water testing; overburden; warranties; and recommendations for building owners.

Guidelines

The Green Roof System Guidelines section provides in-depth technical information about green roof systems' design and installation; however, NRCA recognizes green roof system practices vary considerably throughout the U.S. because of the variety of conditions that exist and various roofing materials available.

Selected plant varieties commonly dictate a green roof system's necessary depth of growth medium. This also helps guide the specific component design.

Of course, when reroofing with a green roof system, a roof deck's structural capacity should be considered. Because of the varying depths of growth medium, NRCA's manual divides green roof systems into the following three primary categories:

- Extensive (shallow): a green roof system with an engineered soil-based growth medium approximately 2 to 6 inches deep

- Semi-intensive (moderate depth): a green roof system with an engineered soil-based growth medium approximately 6 to 10 inches deep

- Intensive (deep): a green roof system with an engineered soil-based growth medium greater than 10 inches deep

A fundamental idea behind the manual's development is that a green roof system is a combination of waterproofing and roofing concepts. Because a green roof system is likely to have moisture present within the system most or all the time, NRCA considers a waterproofing membrane appropriate. And because green roof systems include detailing similar to all other roof system types (parapet walls and roof drains, for example), construction details for green roof system waterproofing membranes are based on termination concepts NRCA considers appropriate for all roof system types.

A semi-intensive (moderate depth) green roof system

Performance attributes, environmental features and common system components for green roof systems are included in the manual, as well. Possible performance attributes include increased thermal efficiency, noise reduction and extended membrane service life. Likely performance attributes are stormwater management, increased efficiency of roof-mounted photovoltaic panels and aesthetic benefits. Economic benefits, as well as LEED® (Leadership in Energy and Environmental Design) benefits, also may be realized.

The manual's green roof system details provide design and installation information for:

- Hot-fluid-applied polymer-modified asphalt membranes

- APP and SBS polymer-modified bitumen sheet membranes

- EPDM membranes

- Polyvinyl chloride membranes

- One- and two-component fluid-applied elastomeric membranes

Specific installation parameters, including minimum membrane thickness and ambient temperature recommendations, are provided for each recommended green roof system waterproofing membrane type. ASTM International standards for materials and application are provided where appropriate.

NRCA recommends membranes be adhered to decks to provide the most stable substrate for green roof system waterproofing membranes. Therefore, thermal insulation used in a green roof system is installed above the membrane or below the roof deck. Positive drainage should be provided by sloping the structural deck.

Construction details

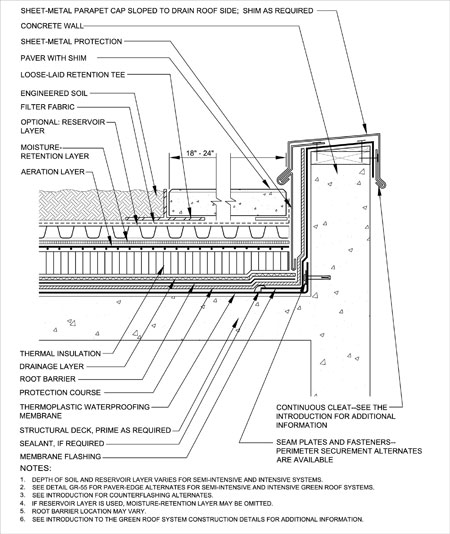

The manual's Green Roof System Construction Details section provides technical information and construction details concerning the design and installation of quality green roof systems. The section's introduction is intended to supplement the special notes on the individual construction details by providing additional information about green roof system components and deck types.

For each membrane type, construction details are provided for eight common conditions. The details are arranged according to membrane type to assist roofing contractors with the submittal process. Additionally, details are provided for substrate crack preparation, nonmoving cold joints, cementitious board joints, sidewall penetrations, area dividers and paver edges.

Low parapet flashing for thermoplastic waterproofing membrane—extensive (shallow) green roof system

Construction detail concepts for green roof waterproofing membranes are similar to those pertaining to common roof system types. Some similarities follow:

- Membrane base flashings are recommended to be a minimum of 8 inches above the surface of the membrane and 4 inches above the overburden's top surface. For green roof systems, mechanical protection is recommended.

- Sheet-metal rain collars are recommended for penetration details, and soft-metal pipe flashing is recommended for vent stacks.

- Sheet-metal counterflashing is recommended for membrane terminations at skylights, scuttles and smoke vents.

- Sheet-metal expansion joint covers that provide movement capability are recommended; however, for green roof systems, expansion joints should be formed of concrete.

- Drain details include membrane compressed between the drain bowl and clamping ring.

- Sheet-metal copings are recommended to include a continuous front cleat and appropriate fastening in the back face. The coping's uplift resistance should meet building code requirements.

NRCA believes an important part of a green roof system project is the verification of the integrity of the system's waterproofing membrane. Before subsequent application of necessary components—from root barrier to growth medium—NRCA strongly recommends a water test be performed.

A water test may consist of a flood test or flowing water test depending on the structural capacity of the deck and slope; each typically lasts a minimum of 24 hours. A water test documents the performance of a green roof system's waterproofing membrane before placement of system components. A water-test verification form is provided in the manual.

A valuable resource

I encourage specifiers, manufacturers and installers of green roof systems to reference The NRCA Green Roof Systems Manual—2007 Edition when designing and constructing green roof systems.

The manual also is available on CD-ROM. The CD-ROM version contains CAD-formatted construction details intended to be altered to meet specific project parameters. To purchase the manual, log on to shop.nrca.net or call NRCA's Customer Service Department at (866) ASK-NRCA (275-6722).

James R. Kirby, AIA, is NRCA's associate executive director of technical communications.