When it comes to the Occupational Safety and Health Administration (OSHA), it seems the agency always has something new in store for roofing operations.

Roofing contractors who operate in states that enforce federal OSHA regulations certainly are familiar with OSHA's construction rules under 29 CFR §1926; they also need to follow OSHA's general industry rules under 29 CFR §1910. In particular, roofing contractors need to comply with general industry rules applicable to construction operations involving hazard communication, respiratory protection and forklift requirements.

OSHA issued another final rule that took effect Jan. 17 that affects a majority of building owners for whom roofing contractors provide services and also may affect some roofing contractors' work. The regulation revises OSHA's general industry rule in Subpart D that addresses slips, trips and falls on walking and working surfaces in all general industry workplaces. In a positive development, the new rule contains some innovative concepts regarding worker safety and fall hazards along with a fall-protection system that has its origins in an established system for roofing work found in the construction regulations.

This new regulation marks one of the few instances where OSHA has placed an affirmative burden on building owners to test, certify and maintain fall-protection anchorages used with a specific fall-protection system. It also may serve to initiate a more comprehensive dialogue among business operators and OSHA to prod the agency to clarify the meaning of "repair" work as the term is used in the construction rules and the concept of "maintenance activities," which OSHA casually uses to outline a segment of the general industry rules, so employers better understand the applicability of both sets of rules.

The history

The general industry regulation relating to fall protection on walking and working surfaces was adopted in 1971 and has not been revised until this year. The original rule generally limits fall-protection system options to the use of guardrails at fall hazards that are 4 feet high or higher. Under the new regulation, the fall-protection system options in general industry more closely mirror those applicable to the construction industry since 1994 except for the retention of the 4-foot threshold as the trigger height.

Conventional fall-protection systems specified under the construction industry rules now are available as general industry options. These include guardrails, safety nets and personal fall-arrest (PFA) systems—with added provisions for the use of travel-restraint systems, positioning systems and a fall-protection plan.

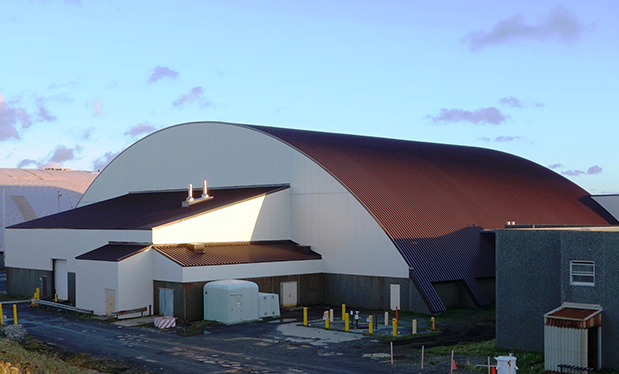

Most significantly, in certain instances on low-slope roofs (4-in-12 or less), a general industry employer may protect workers by establishing a designated area, which is a distinct portion of a walking or working surface delineated by a warning line in which employees may perform work without additional fall protection. This new option clearly is based on the warning-line system available for roofing work on low-slope roofs that has been part of the construction rules for years.

A key benefit promoted by OSHA under the new rule is the flexibility offered to employers to select the fall-protection system most appropriate for the fall hazard involved. Although noting this idea comes from the construction regulations, OSHA has moved to reduce fall-protection systems options available in construction during the past few years by, for example, rescinding slide guard use in steep-slope roofing. This new rulemaking is something of an anomaly with respect to past agency actions.

The new regulation is critical for a number of entities. OSHA was given authority under the Occupational Safety and Health Act of 1970 to develop and enforce rules covering various industries, including construction, maritime and general industry. The general industry rules apply broadly to employers in manufacturing, warehousing, retail and industrial workplaces (the rules' applicability is determined not by an agency definition of "general industry" but more by the work that remains after defining the scope of the other named industries). Application of maritime rules for ship building and repair clearly is mandated, and "construction work" is less clearly defined as "work for construction, alteration, and/or repair, including painting and decorating." OSHA historically has considered "maintenance activities" to be covered under general industry rules.

A 2003 OSHA letter of interpretation relied on a definition in the Davis-Bacon Act when the agency was struggling to distinguish repair work from maintenance activities. The letter cited that law's equally vague definition of construction work: "In essence, 29 CFR 5.2(i) defines construction work as 'generally includ[ing] construction activity as distinguished from manufacturing, furnishing of materials, or servicing and maintenance work. …'"

In the letter, OSHA explains maintenance means "keeping equipment working in its existing state, i.e., preventing its failure or decline." But a project's scale and complexity may indicate a construction characterization. Complexity is assessed based on the steps involved to accomplish a task and the tools and equipment needed to perform the work. It doesn't matter to OSHA whether workers performing the tasks are employed by an outside contractor or in-house employees of the building or property owner; the rules apply uniformly. The significance of these distinctions for roofing contractors relates to the specific work a contractor may perform before determining whether general industry or construction fall-protection options are appropriate.

System specifics

The new OSHA rule requires employers to provide fall protection for any employee on a walking or working surface with an unprotected side or edge that is 4 feet high or higher above a lower level using one or more of the following: guardrails, safety nets, PFA systems, travel-restraint systems or positioning systems. As in construction, for residential roofs, if an employer can show those systems are infeasible or create a greater hazard to workers, the employer must develop and implement a fall-protection plan that complies with the elements of 29 CFR §1926.502(k).

Specific requirements of a guardrail system generally match those in the construction rule: A guardrail must be 39 to 45 inches tall; its top rails must withstand a force of 200 pounds in a downward or outward direction; its midrails must be installed at the midpoint between the top rail and walking or working surface; and midrails must be at least 1/4 of an inch thick to allow for the use of rope or wire rope (no flagging is required as under the construction rule).

The requirements for safety nets are the same as in the construction rule. PFA system components must be able to sustain a minimum tensile load of 5,000 pounds, and anchorages supporting the system must be capable of supporting 5,000 pounds per employee attached. The same 5,000-pound requirement applies to travel-restraint lines though OSHA offers no specifics for the other components of a restraint system. Self-retracting lifelines must limit a free fall to 2 feet or less and be capable of sustaining a minimum tensile load of 3,000 pounds. Also, the agency gives no direction regarding rescue from an arrested fall. Rather, it duplicates the vague requirement from the construction rule that an employer must provide for the prompt rescue of a worker in the event of a fall.

With regard to low-slope roof systems, one of the fall-protection systems described must be used if workers are less than 6 feet from the roof edge. When work is at least 6 feet but less than 15 feet from a roof edge, one of those systems must be used or the employer may implement a designated area if the work is infrequent and temporary. A designated area is part of the walking or working surface delineated by a warning line within which employees may perform work without additional fall protection. The warning line of the designated area must be visible from a distance of 25 feet and from anywhere within the designated area.

Warning-line height, strength and support requirements from the construction rule also apply to general industry use as do the distances from the edge for warning-line placement when mechanical equipment is used: 6 feet from the edge parallel to equipment travel and 10 feet from the edge perpendicular to equipment travel. Importantly, when work is performed 15 feet or more from a roof edge, workers may be protected with guardrails, safety nets, PFA systems, travel-restraint systems or a designated area; however, if work is infrequent and temporary, no fall protection is required provided the employer implements and enforces a work rule prohibiting employees from going within 15 feet of the roof edge unless they use a fall-protection system.

The new general industry rule also contains a provision similar to one found in the construction rule for workers who inspect, investigate or assess the work to be performed or workplace conditions before work starts or after work has been completed. These workers are not required to have fall protection unless fall-protection systems or equipment have been installed and are available. This is an important provision most likely to be applied to building engineers and maintenance personnel who previously had never been covered by such an exception.

Ladders

OSHA essentially has copied the portable ladder use provisions from the construction rules into the new general industry ladder requirements. This includes the confusing and poorly worded rule that "no employee carries any object or load that could cause the employee to lose balance and fall while climbing up or down the ladder." The new rules related to fixed ladders will require action on the part of many building owners, and roofing contractors need to be aware of the consequences of the rule, as well.

Under the rule, fixed ladders extending more than 24 feet from the level below and installed before Nov. 19, 2018, must be equipped with a PFA system, ladder safety system, cage or well. Fixed ladders installed on or after that date must be equipped with a PFA or ladder safety system. OSHA defines a ladder safety system as one designed to eliminate or reduce a fall and usually consisting of a carrier, safety sleeve, lanyard, connectors and a body harness. The rule states "the employer must ensure" one of the fixed ladder fall-protection systems is in place, which generally puts the compliance burden on the building owner to protect all users of the fixed ladder.

However, roofing workers engaged in construction work must ensure a fixed ladder with a height greater than 24 feet above the lower level is equipped with a ladder safety device, self-retracting lifeline, or cages and wells. Rest platforms are required at different heights depending on the nature of the fixed ladder. If none of these systems is in place on a fixed ladder, a roofing contractor must make alternative arrangements for access or ensure compliance through use of a ladder safety device or self-retracting lifeline by workers using the fixed ladder. A fixed ladder also must not be used if OSHA specifications for rung or tread dimensions and clearances, access distances, and cage and well dimensions are noncompliant.

Anchorages

Under the rule, rope descent systems (RDSs), such as those used for window washers, must have anchor points capable of supporting 5,000 pounds per worker attached. OSHA has established an affirmative obligation on the part of the building owner to identify, test, certify and maintain each RDS anchor point used with RDSs. No employer may allow a worker to use an RDS anchor unless the employer has received written information from the building owner that the anchor meets the strength requirements. A similar provision is in the powered platform regulation in Subpart F of the general industry rule. However, no comparable requirement can be found in the construction regulations that requires a building owner to verify the strength of permanent anchor points for fall-protection equipment contractors may use.

Follow the rules

Many of the new general industry fall-protection provisions appear similar to construction regulations, but roofing contractors must rely on the OSHA rules specific to construction for fall hazards and control methods.

Specifically, absent further direction from the agency as to what might constitute maintenance activity (general industry rules apply) versus repair (construction industry rules apply), roofing contractors should be particularly wary when attempting to use the designated area options under the new rule for work that could be characterized as construction or repair. This is true even if the activity clearly meets the accompanying regulatory requirement of being temporary and infrequent. To ensure OSHA compliance and maintain the safety of roofing workers, the designated area option and fall-protection exemption at distances of 15 feet or greater are best viewed under the narrow scope of where they are found—as a general industry provision alone.

Safety often can be a casualty when OSHA issues new regulations that cause confusion about the work operations covered and the precise nature of the worker protection to be enforced. When properly implemented, established fall-protection systems provide trained roofing workers with familiarity, ease of setup and use, and dependability to deliver a safe work area.

Harry Dietz is an NRCA director of risk management.

To read more about this topic, see "So … you think you know safety?", November 2016 issue.