When you are preparing to begin a roofing job, you must assess potential hazards at the job site and require that each worker use personal protective equipment (PPE) to maintain a safe working environment. General PPE includes gloves, American National Standards Institute (ANSI)-approved hard hats, eye protection with side shields and protective footwear.

But often, specific roofing activities require additional types of PPE. An example would be the use of respiratory protection by roofing workers applying solvent-based bonding adhesive on a fully adhered single-ply roof membrane and substrate in a poorly ventilated roof area. Another example would be the use of full-face shields and hard hats by kettle operators to protect their faces from hot bitumen splashes. However, one potential job-site hazard often is overlooked—noise.

Addressing noise

Ten million Americans have suffered irreversible noise-induced hearing loss, and 30 million more are exposed to dangerous noise levels each day, according to the National Institute on Deafness and Other Communication Disorders. Noise hazards at construction sites can originate from a variety of sources, including equipment operated by roofing workers during roof system installation, retrofit or tear-off. Sometimes, noise levels generated from other heavy construction equipment, such as pile drivers, material handlers, concrete breakers and earthmovers, can exceed permissible noise levels as defined by the Occupational Safety and Health Administration (OSHA). The obligation placed on you to protect your employees from all noise exposures is clear, regardless of the source of noise or the trade responsible for loud equipment operation.

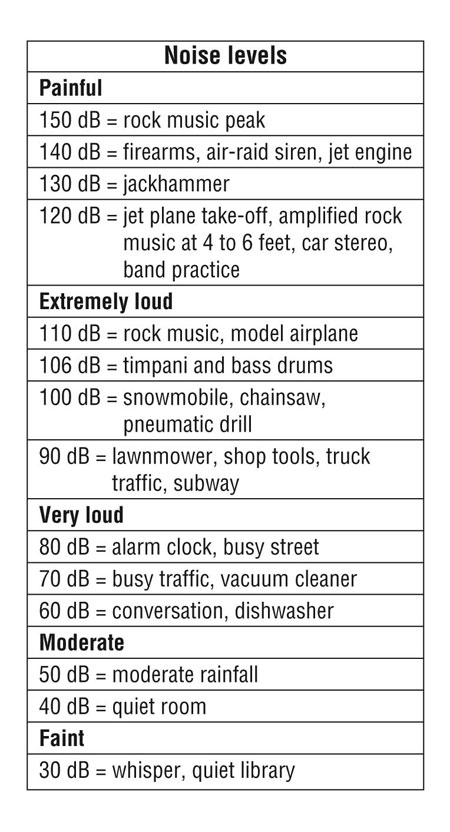

Some types of power tools and hand tools also can generate noise that exceeds permissible exposure levels. Examples include powder-actuated tools and pneumatic nail guns, roof cutters and generators. Hot bitumen kettle operators can be subjected to higher than permissible noise levels from motorized pumps and active propane burners. And roofing workers who cut counterflashing receivers or reglets into masonry or concrete walls can incur higher than permissible noise exposures from masonry saws. Generally, the louder a noise—as measured in decibels (dB)—the shorter the exposure time before hearing protection is required.

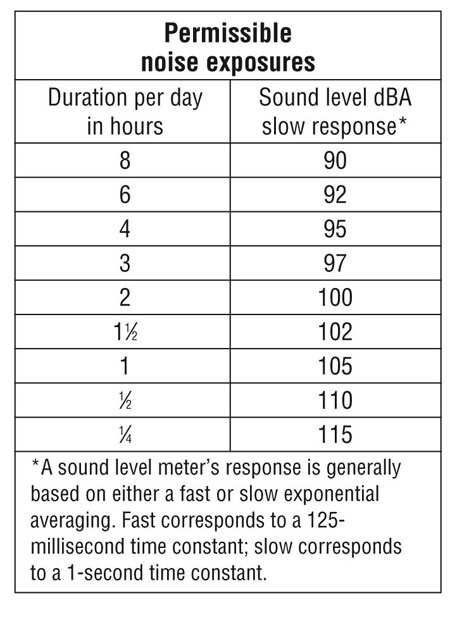

Figure 1: According to the Occupational Safety and Health Administration, protection against the effects of noise exposure must be provided when sound levels measured in decibels with an "A" sound level filter (dBA) exceed those shown in the table.

OSHA requires hearing protection when "it is not feasible to reduce the noise levels or duration of exposures" below prescribed limits. Permissible noise levels and durations are outlined in OSHA standard Subpart D, 29 CFR 1926.52, "Permissible noise exposures," Table D-2. (See Figure 1.)

The first line of defense OSHA requires roofing contractors to take when sound levels exceed those listed in Table D-2 is to implement feasible administrative or engineering controls, such as a muffler on a gas-powered piece of equipment to reduce noise levels. If such controls fail to reduce a noise level to within the limits set in Table D-2, PPE—as described in OSHA standard Subpart E—must be provided and used to reduce noise levels.

If you wish to take a proactive approach to monitoring and managing job-site noise levels, you can purchase sound level meters, or dosimeters, from safety equipment suppliers. These hand-held units generally have measuring ranges from 20 to 140 dB. Use of a dosimeter is the most effective method of ascertaining whether job-site equipment is producing noise at a level that must be addressed through the use of engineering or administrative controls or PPE.

Protect your workers

There are various warning signs workers may exhibit to indicate job-site noise levels are approaching a hazardous level, including:

- Raising their voices to be heard

- Inability to clearly hear somebody standing a few feet from them

- Difficulty hearing immediately after leaving a noisy area

- Ringing in their ears after being exposed to high noise levels

Tear-off and demolition crews are more prone to overexposure to high noise levels from mechanized equipment, such as roof cutters, gravel sweepers and vacuums, which generate noise from engine operations and contact with roofing material being removed. If you use the same crew to tear off and reinstall roof systems, provide workers with appropriate PPE and consider rotating workers' activities to prevent overexposure to high noise levels.

Figure 2: Average decibel (dB) levels for everyday sounds Provided by the American Speech-Language-Hearing Association

There are various types of hearing protection available. For example, single-use earplugs are made from foam, silicone or rubber. They are self-forming and, when properly inserted, work as well as preformed plugs. Molded earplugs are fitted by a professional and can be reusable or disposable. Earmuffs are another option. They cover the entire ear but must create a seal to work properly—eyeglasses, long hair and even facial movement can diminish their effectiveness.

All hearing protection devices should have a noise reduction rating (NRR) stamped on them or their packaging. This numeric rating indicates a device's effectiveness in reducing the amount of noise transmitted to a wearer's ear. The higher the number, the greater the theoretical protection afforded by the device. The NRR is a simple way to compare the protective capabilities of the many products available for worker hearing protection.

A proposal

In March, The Bureau of National Affairs Inc. reported that the American Industrial Hygiene Association (AIHA) had asked OSHA to lower the permissible exposure limit for occupational noise from a 90-dB time-weighted average during an eight-hour workday to an 85-dB time-weighted average. Further supporting AIHA's cause, ANSI proposed a modified standard addressing identification of situations, tools, tasks and work areas that, based on their documented typical noise levels, require efforts to minimize noise exposure. This proposal would then require administrative or engineering controls to restrict exposure or, if not feasible, the distribution and use of PPE. It is expected this proposed standard will be published and printed sometime this summer.

Be proactive

Effectively managing noise-related issues on roofing job sites requires assessing workers' actual noise exposures, a listing of equipment that produces noise and the decibel level for each piece of equipment. You can then determine a compilation of possible administrative and engineering controls to reduce worker exposures, select appropriate hearing protection devices, and provide workers with training regarding noise hazards and proper use of PPE to reduce overexposure to noise.

Chuck Scislo is NRCA's director of training.